Large heavy workpiece lathe conveying device

A technology for handling devices and workpieces, applied in automatic/semi-automatic lathes, turning equipment, manufacturing tools, etc., can solve the problems affecting assembly accuracy and reliability, long clamping time, affecting the function of the whole machine, etc., to improve work efficiency, The effect of shortening clamping time and avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

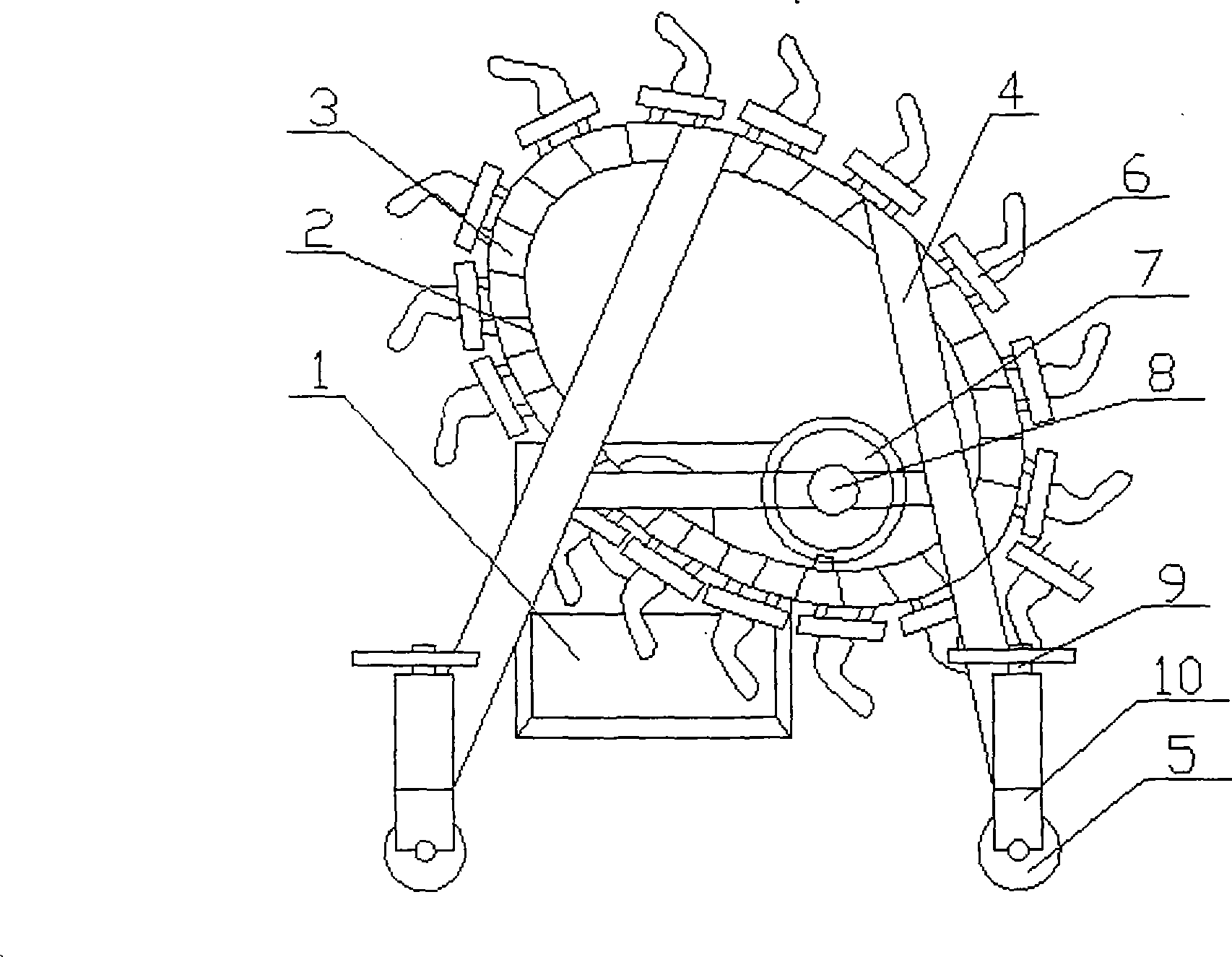

[0011] The accompanying drawing is an embodiment of the present invention, and this embodiment is described in detail in conjunction with the accompanying drawings, including a track 2, a transmission bar 3, a bracket 4, a fastening device 6, a transmission wheel 7, a handle 8, a universal wheel bracket 10 and a universal To the wheel 5, the track 2 is set to an ellipse and one side is provided with an inner groove, the track 2 is set to two and is arranged on the two ends of the transmission bar 3 and is arranged to be fixedly connected with the bracket 4, and the transmission bar 3 is set to multiple pieces and It is bar-shaped and arranged in the inner groove of the track 2, the transmission wheel 7 is set as a gear, the transmission wheel 7 and the handle 8 are set to be fixedly connected with the bracket 4 through a fixed shaft and the handle 8 is set to be fixedly connected to the transmission wheel 7, and the transmission wheel 7 is set to be connected with the inner sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com