Sectional material dynamic controllable forming device

A dynamic and profile technology, applied in the field of profile dynamic controllable forming devices, can solve the problems of inability to meet efficiency, processing quality and precision, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

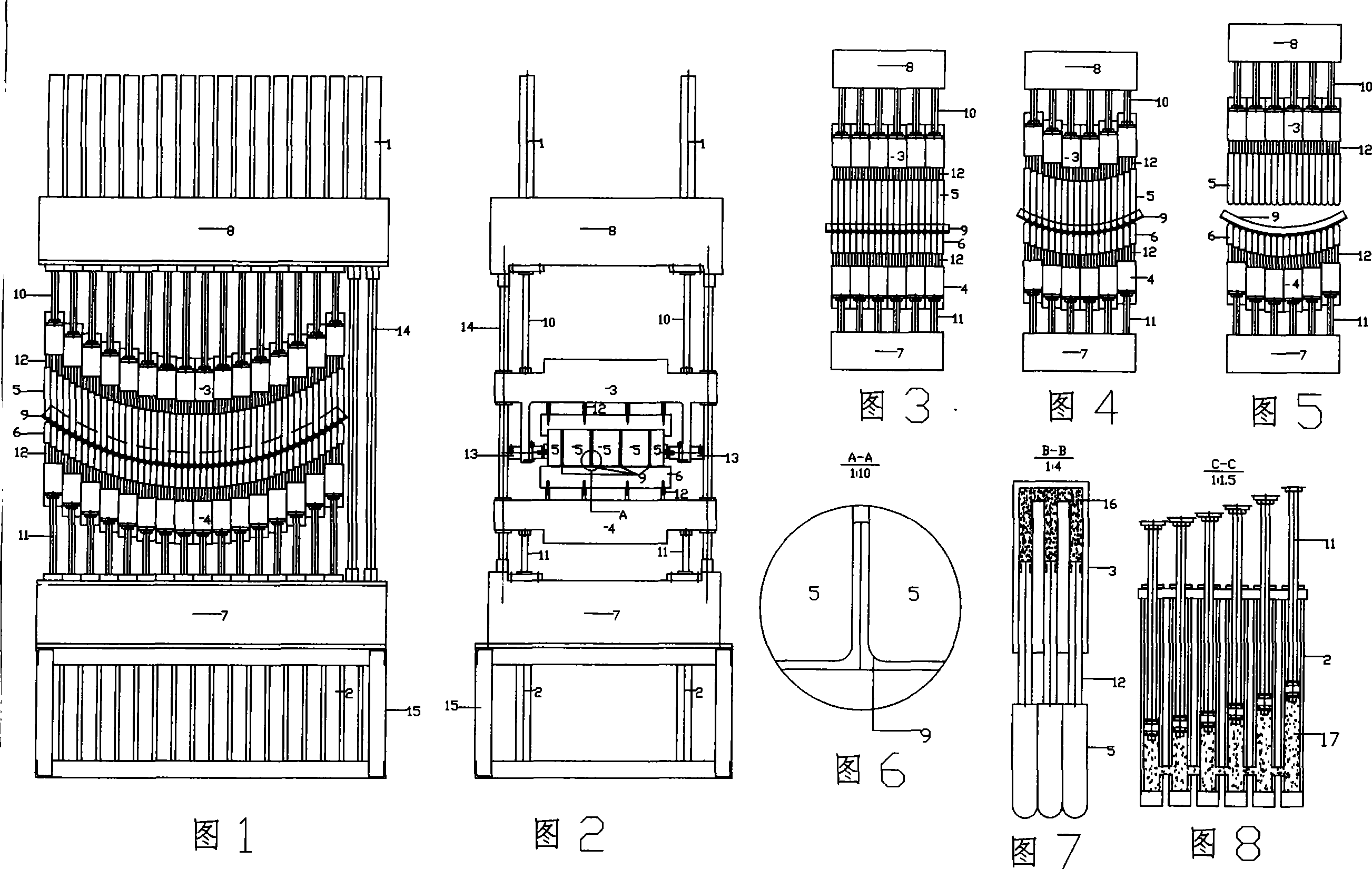

[0019] Referring to Figures 1, 2, 3, 4, 5, 6, 7, and 8, the profile dynamic controllable forming device includes a hydraulic frame 15, and the hydraulic frame 15 is provided with fixed upper and lower beams 8, 7, an upper beam 8 and a lower beam 7 At least two pairs of vertical guide cylinders 14 are installed between them, and each pair of guide cylinders 14 is provided with movable beams 3 and 4 that can slide up and down; the upper beam 8 is equipped with multiple pairs of closely arranged loading hydraulic cylinders 1, each The lower end of the piston rod 10 of a pair of loading hydraulic cylinders 1 is fixedly connected to the corresponding upper movable beam 3. The upper movable beam 3 is provided with four built-in auxiliary hydraulic cylinders 16, and the lower end of the built-in auxiliary hydraulic cylinder piston rod 12 is equipped with an upper mold head 5 The lower crossbeam 7 is also correspondingly equipped with multiple pairs of closely arranged load-bearing hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com