Magnetic drive

A magnetic motive and magnetic ring technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems of complex structure, no magnetic motive, and the power cannot meet the requirements of supporting equipment, and achieve the effect of protecting the ecological environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

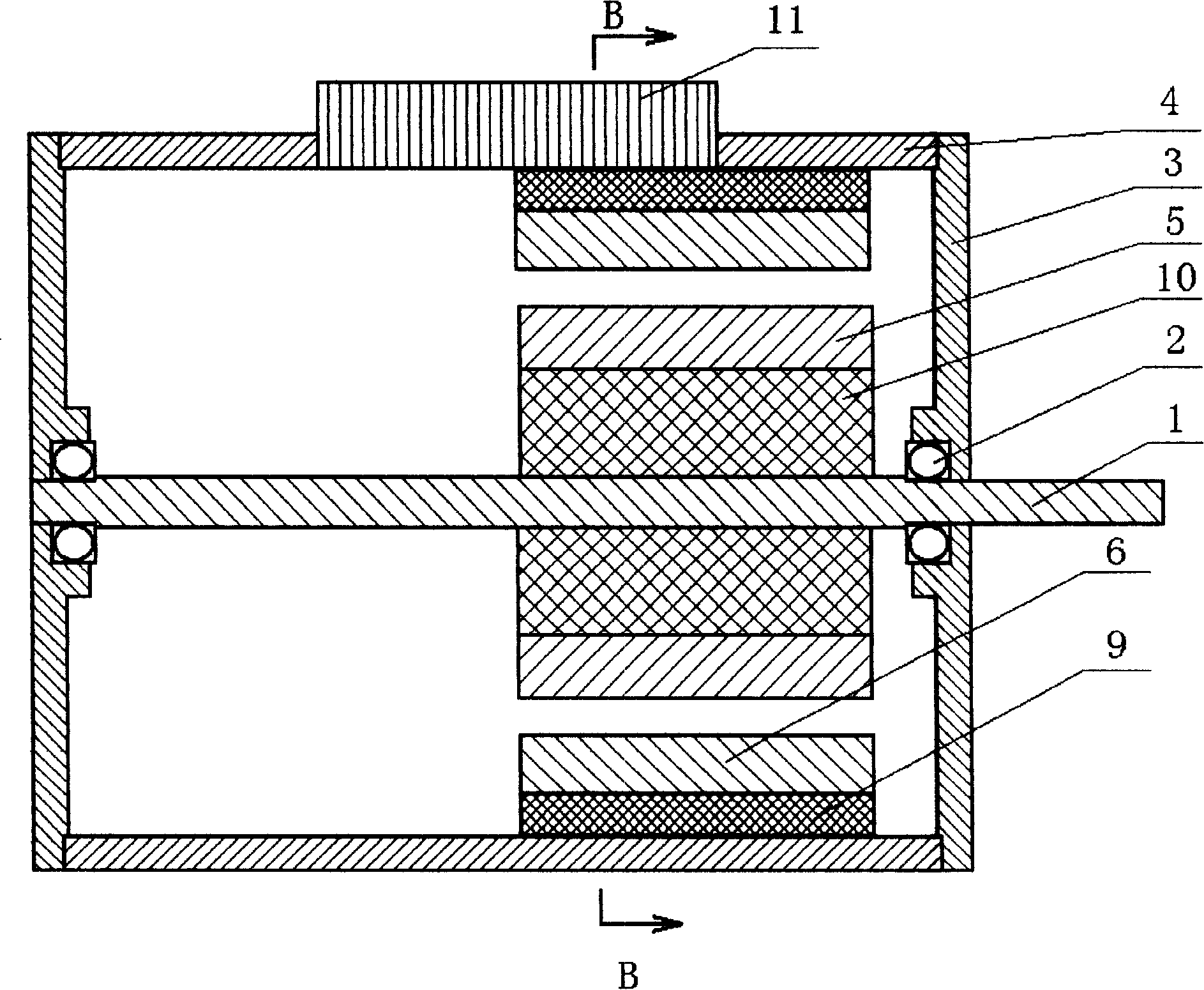

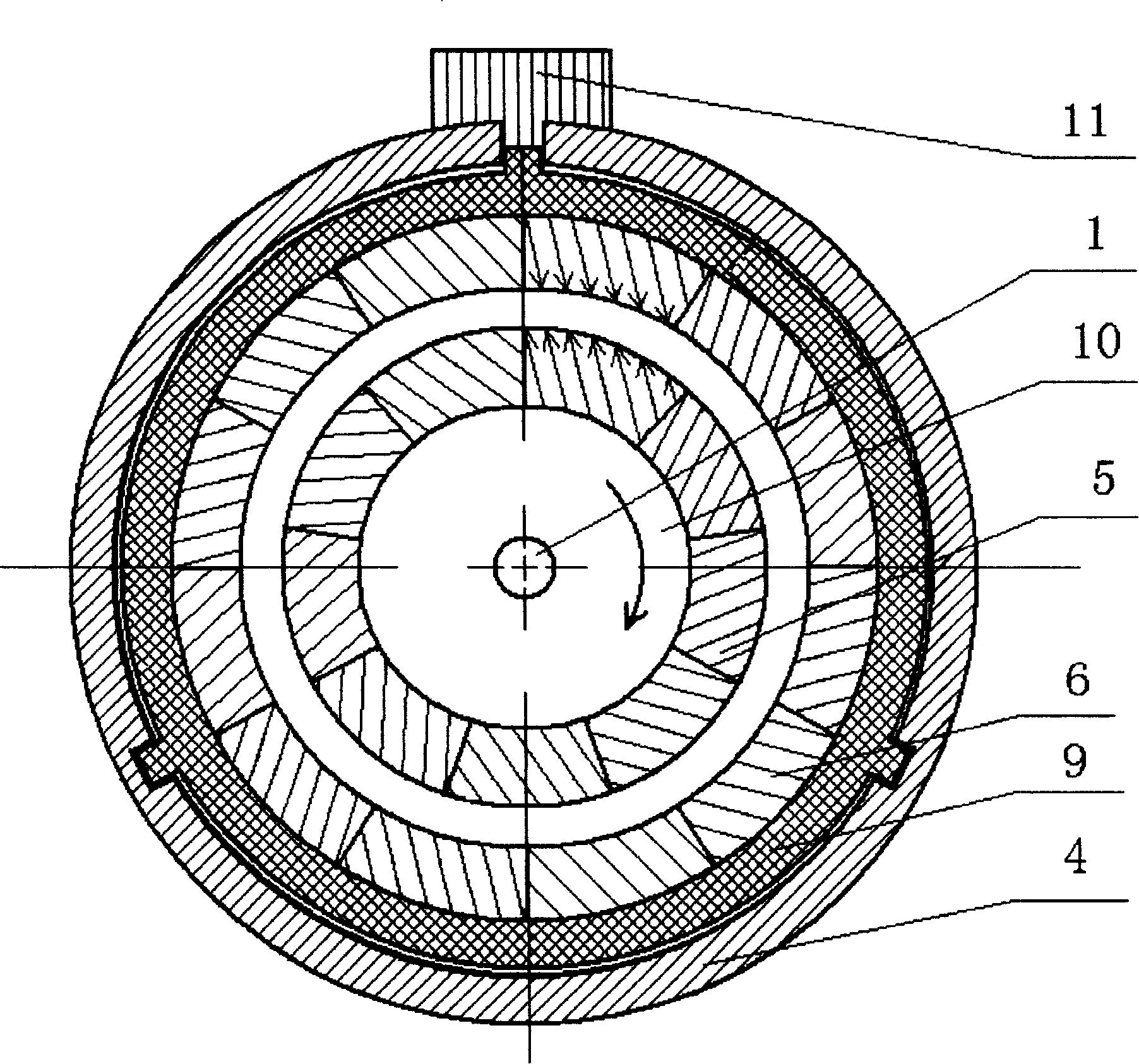

[0026] Such as figure 1 The magnetic motor shown is composed of a rotor assembly a, a stator assembly b, a bearing seat 3, a casing 4, and a speed regulating and positioning device 11, and its characteristics are: the rotor assembly a passes through the bearing seat 3 and is installed on the casing 4 The two ends of the rotor make the rotor circular magnetic ring 5 suspended in the stator circular magnetic ring 6. The speed regulating and positioning device 11 is connected with the stator assembly b through the concave rail at the upper end of the housing 4 . The stator assembly can be moved and positioned along the axial direction in the concave rail of the housing.

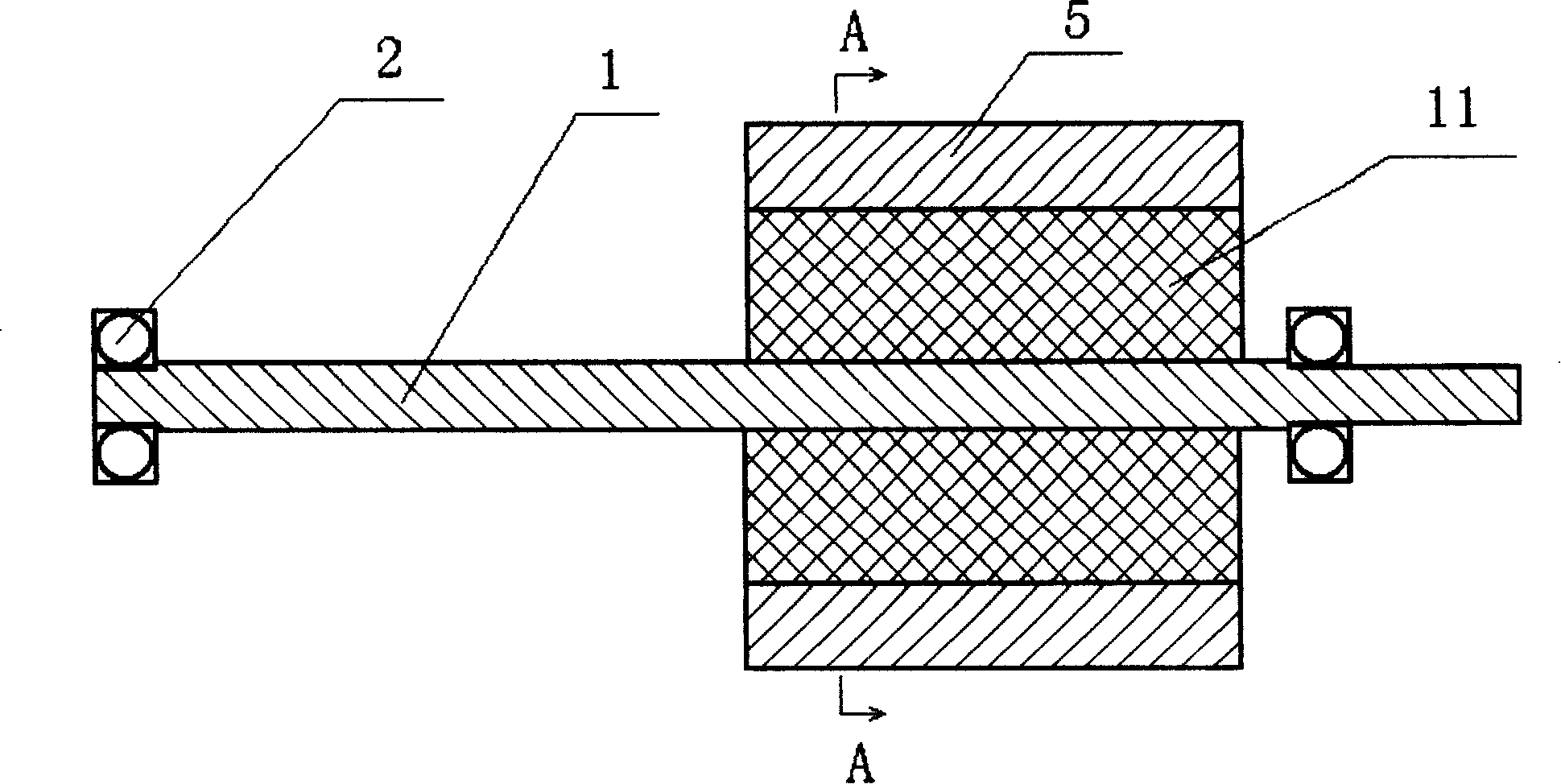

[0027] The rotor assembly a is composed of a rotating shaft 1, a bearing 2, a rotor circular magnetic ring 5, and an inner bushing 10, and is characterized in that: the rotor circular magnetic ring 5 is fixedly connected to the rotating shaft 1 through the inner bushing 10, and There are bearings 2.

[0028] ...

Embodiment 2

[0037] According to the above principles, multiple sets of magnetic power units can also be installed to generate greater power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com