Microwave sulphur lamp bulb preparation method

A light bulb and sulfur lamp technology, which is applied in the field of microwave sulfur lamp bulb preparation, can solve the problem that the amount of sulfur and Ar gas charged is not easy to control, and the high vacuum degree of the bulb preparation device, the luminous brightness and efficiency of the sulfur lamp, and the color rendering property cannot be guaranteed. and low service life to achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

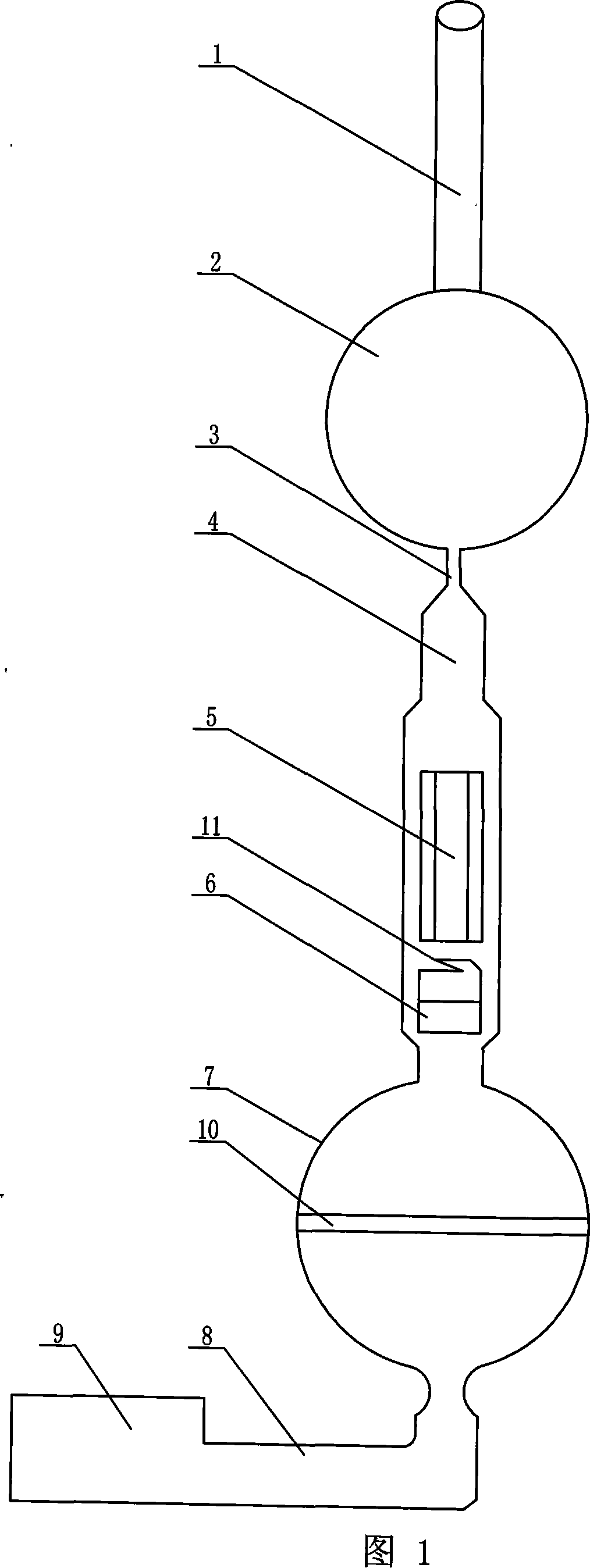

[0012] Specific implementation manner 1: This implementation manner is described in conjunction with FIG. 1 . The steps of the preparation method of the quartz bulb 2 of the present embodiment are as follows:

[0013] Step 1, prepare a device consisting of a solid glass rod 1, a quartz bulb 2, a glass thin tube 3, a transition glass tube 4, a filter ball 7 and a glass tube 8, the quartz bulb 2, the glass thin tube 3, the transition glass tube 4, filter The ball 7 and the glass tube 8 are sequentially connected and communicated from top to bottom, the solid glass rod 1 is set on the top of the quartz bulb 2, the upper part of the transition glass tube 4 is provided with a magnetic weight 5, and the lower part of the transition glass tube 4 is provided with a A glass container 6, the glass container 6 is filled with sulfur powder with a mass of 50-80 mg, a protruding glass tip 11 is arranged on the top of the glass container 6, the filter ball 7 adopts G3 type, and the left open...

specific Embodiment approach 2

[0019] Specific embodiment two: The difference between this embodiment and specific embodiment one is that in step two, heat at 400°C to vacuumize, fully discharge the residual gas in the device, and maintain the vacuum degree in the quartz bulb 2 at 2×10 -4 pa. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 4, the sulfur powder in the glass container 6 is heated to 444°C. Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com