Cutting type silica gel sheet and its processing method

A processing method and technology of silica gel sheets, which are applied to electrical components, electric switches, circuits, etc., can solve the problems of raw material waste, damage, and inflexibility, and achieve the effects of reducing production costs, simple processing methods, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

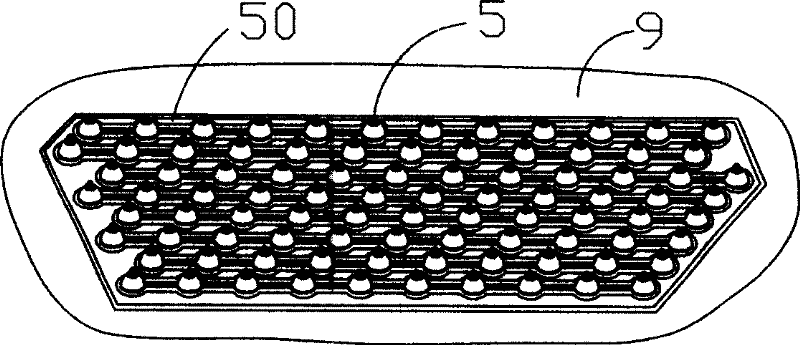

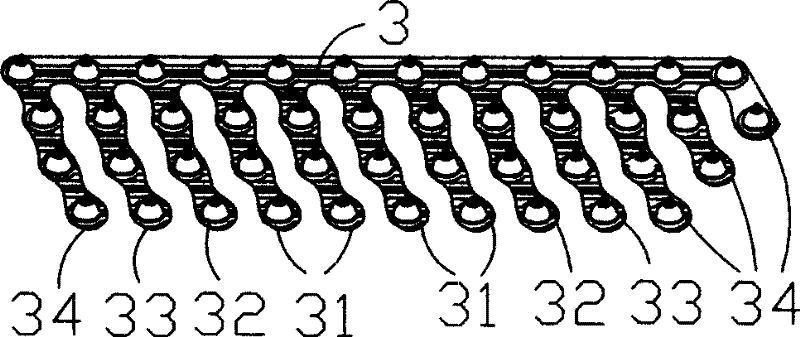

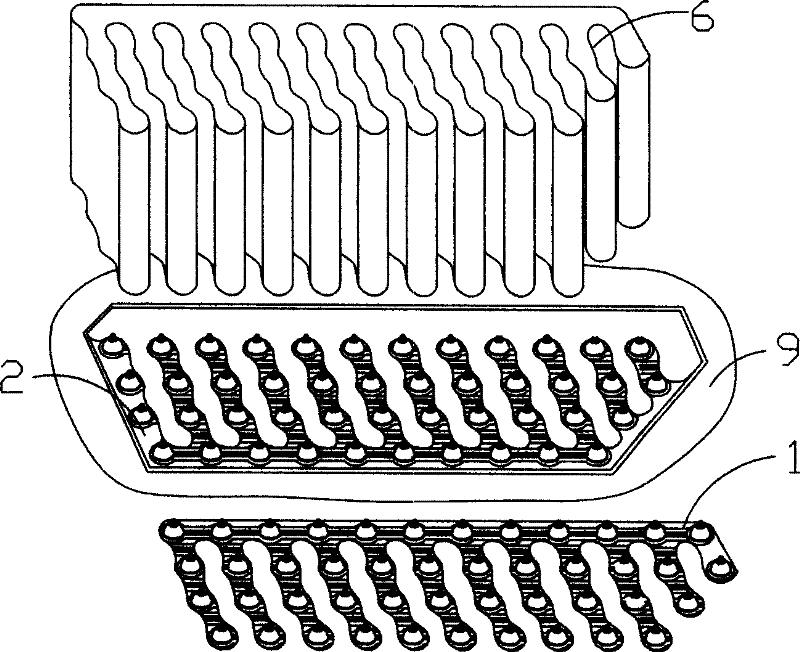

[0022] A cutting-type silicone sheet, including a trunk 3 and a combination of cutting-type strip-shaped rubber caps distributed with several branches on the same side, at least including the index finger corresponding to each index finger button, middle finger button, ring finger button and little finger button in the main keyboard area 4 Rubber cap strap 31, middle finger rubber cap strap 32, ring finger rubber cap strap 33 and little finger rubber cap strap 34, refer to figure 2 shown, and matches the circuit film 30 corresponding to the main keyboard area 4, refer to Figure 4 , Figure 5 shown.

[0023] During specific implementation, the silicone strength of each rubber cap group corresponding to the rubber cap band 31 for the index finger, the rubber cap band for the middle finger 32 , the rubber cap band for the ring finger 33 and the rubber cap band for the little finger 34 is arranged in order from large to small. If the rubber cap silicone force in the index fing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com