Friction facing and friction clutch with such a friction facing

A friction lining and clutch disc technology, applied in the fields of friction clutches and friction linings, can solve the problem of not being able to completely prevent the warping of friction materials, and achieve the effect of reducing the fiber part, small volume and high bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

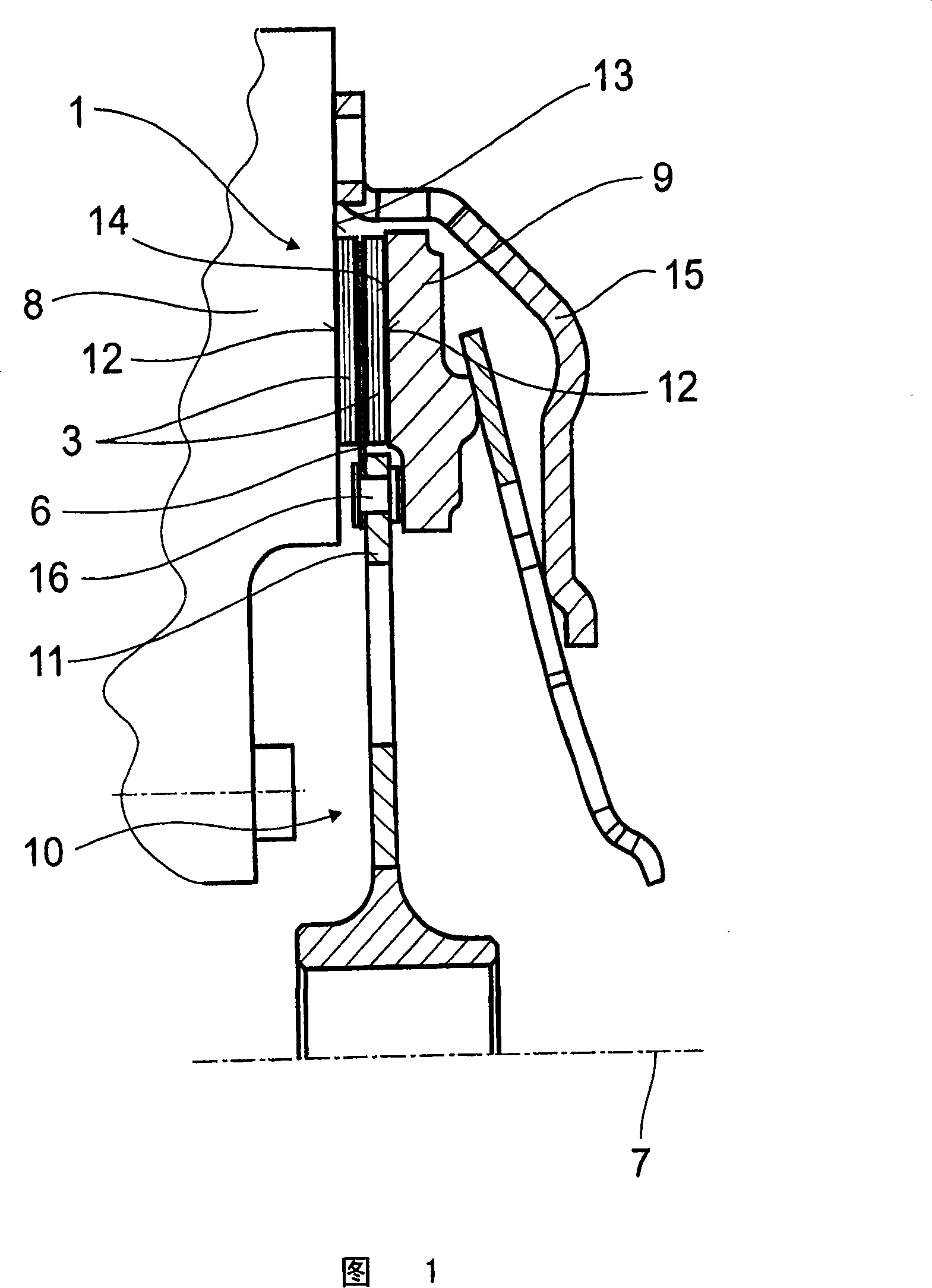

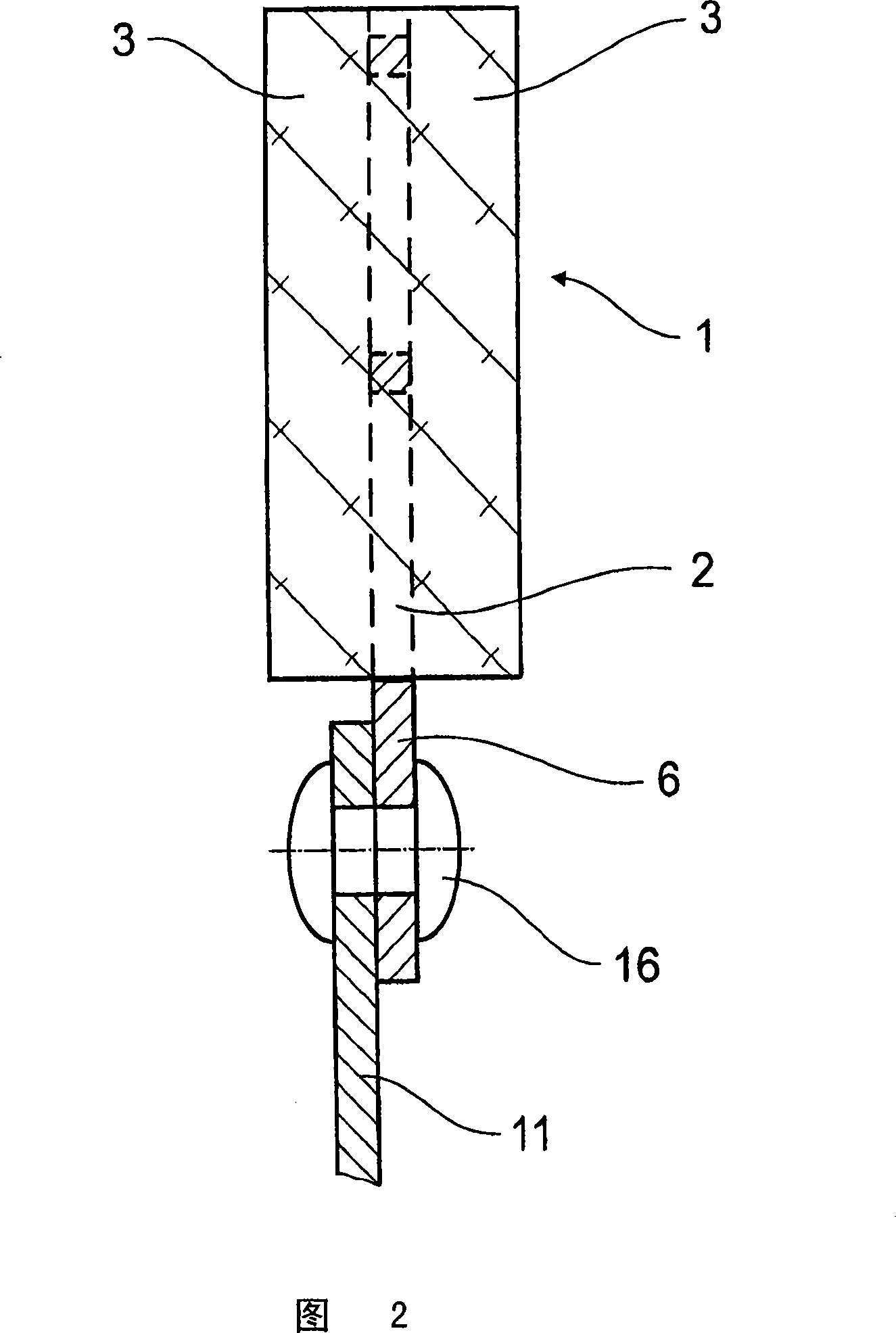

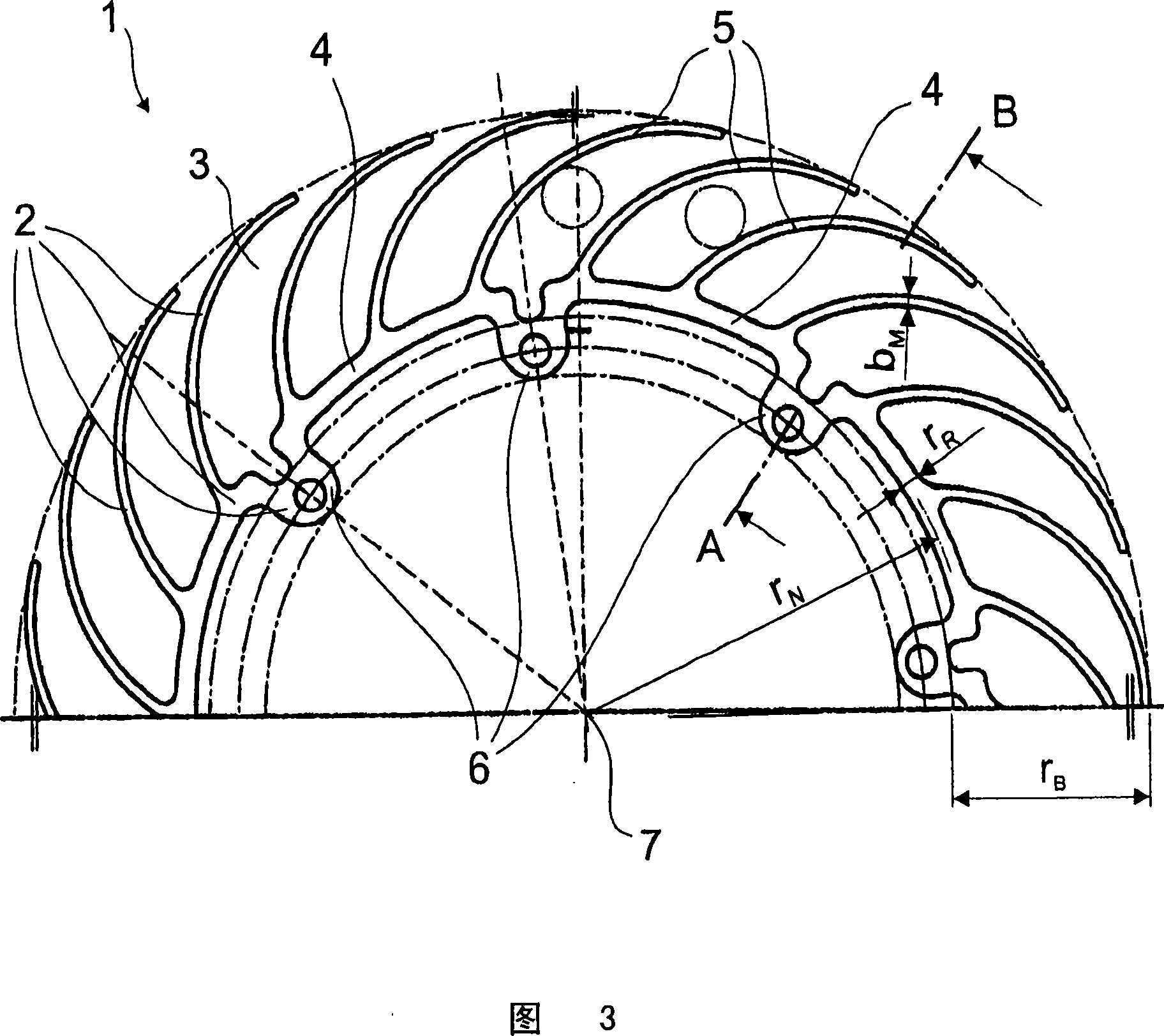

[0045] In FIG. 1 , a radial section through a motor vehicle friction clutch constructed in a known manner can be seen, a clutch disc 10 is arranged between a flywheel 8 and a pressure cover 9 , wherein by applying an axial pressure force , the compression cover plate 9 establishes a frictional connection between itself, the clutch disc 10 and the flywheel 8 . The components rotate about the axis of rotation 7 ; they are covered by the clutch outer body 15 .

[0046] The clutch disk 10 has a carrier disk 11 on the radially outer region of which a friction lining 1 is fastened by means of a riveted connection 16 . When an axial force is applied, the surface 13 of the flywheel 8 presses against the (left) surface 12 of the friction lining 1 and the (right) surface 12 of the friction lining presses against the surface 14 of the pressure plate 9 .

[0047] Here, the friction lining itself consists of a support element with friction material 3 on both sides. Details here are obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com