Gypsum calcining system

A gypsum and calcination technology, which is applied in the system field of calcination gypsum, to achieve the effect of improving efficiency and quality, improving efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

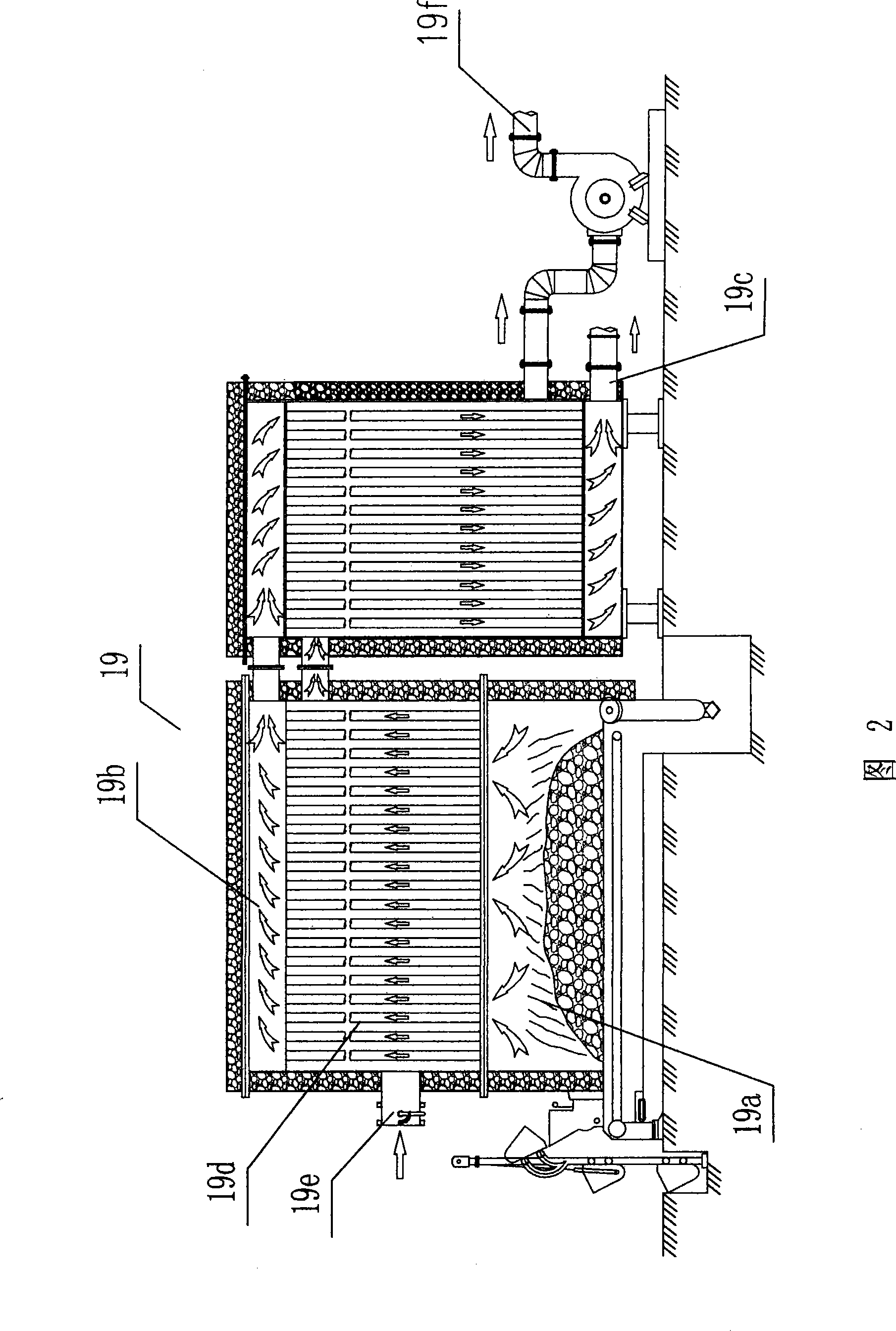

[0028] The gypsum drying device 6 includes a shell 61, the shell 61 is provided with a heat exchange jacket 62, a hot air inlet 63 and a hot air outlet 64 connected to the heat exchange jacket 62, the hot air The inlet 63 is connected to the hot air outlet 19f of the hot blast boiler heat exchanger, and the hot air outlet 64 is connected to the combustion chamber air inlet 19g of the hot blast boiler; the inner cavity of the housing 61 is equipped with a spiral stirring The shaft 65, the stirring blade 65a installed on the spiral stirring shaft 65, the feeding port 66 which is arranged at one end of the housing 61 and communicates with the inner cavity of the housing 61, is arranged at the other end of the housing 61 And the discharge port 67 communicating with the inner cavity of the housing 61, the housing 61 is also provided with an exhaust device 68, and the exhaust device 68 includes a The exhaust pipe is equipped with an induced draft fan, which further improves the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com