Method for measuring air leakage in mine

A technology of air leakage and mine, which is applied in the direction of measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc., which can solve the problems of unmeasured air leakage and high gas cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] To illustrate the method, the following example illustrates the principle of the method:

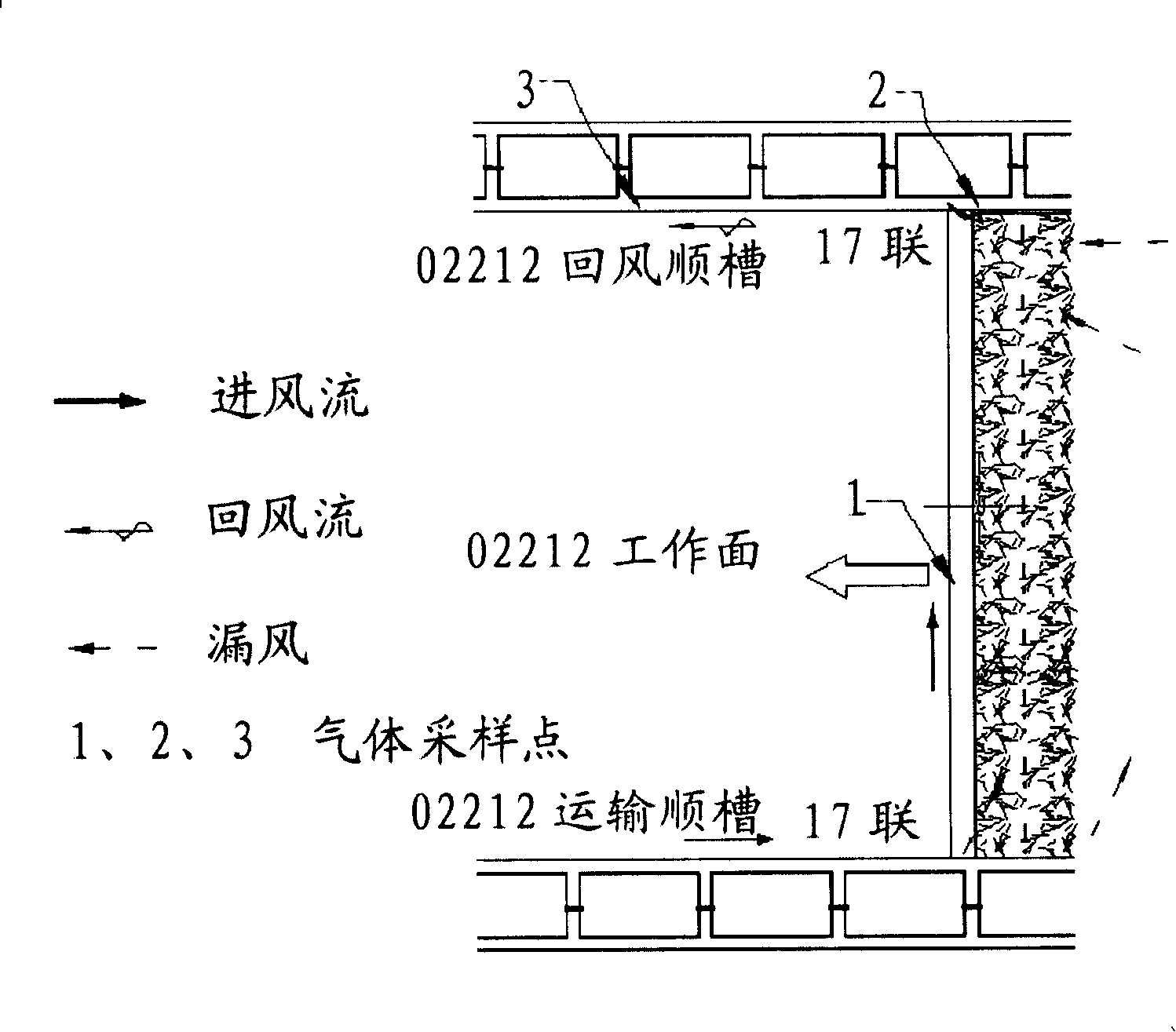

[0027] see figure 1 , taking a coal mine 02212 as an example, the air leakage value of the coal mine was measured.

[0028] 1. Measure the air volume Q at the mining face, the gas concentration at the mining face A1, the air leakage gas concentration A2, and the return air flow at the working face (that is, after the gas at the mining face and the air leakage gas are merged and mixed) the gas concentration A3:

[0029] The air intake Q of the fully mechanized mining face is 2330m 3 / min; three gas sampling points 1, 2, and 3 shown in the figure were selected for gas sampling, and sampling point 1 was located in the air inlet flow stope space of the fully mechanized mining face.

[0030] Gas analysis was carried out by gas chromatography.

[0031] Here, any existing technology can be used to measure the air intake Q of the fully mechanized mining face; gas chromatograph can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com