Metal V-shaped members and light steel truss connected thereby

A metal and truss technology, applied in truss structures, truss beams, joists, etc., can solve the problem of inconvenient connection between metal V-shaped parts and chords, low local pressure bearing capacity and stable bearing capacity, and reduced components at the joint Bearing capacity and other issues, to achieve the effect of beautiful appearance, large bearing capacity, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

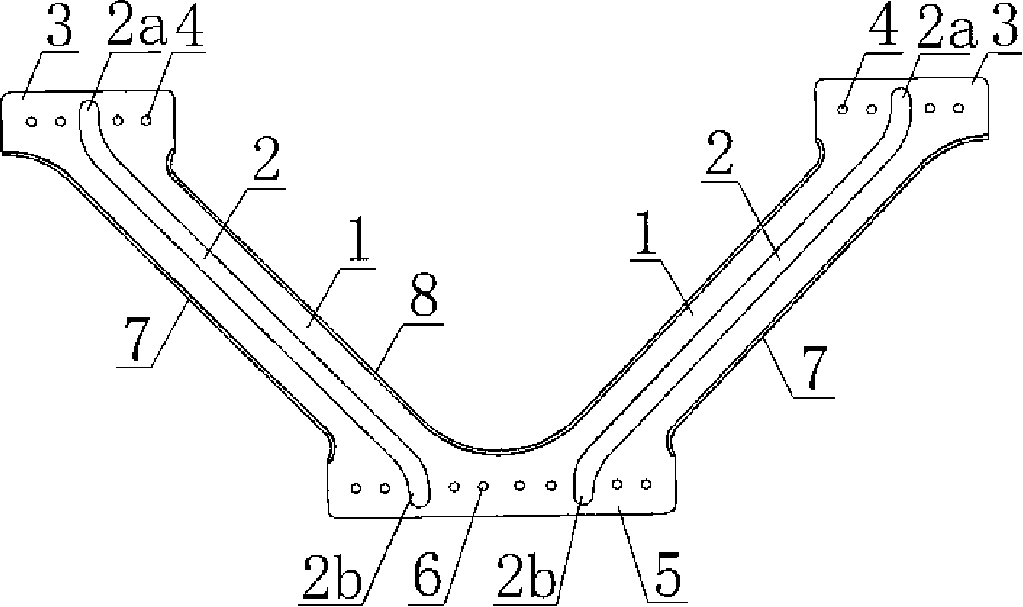

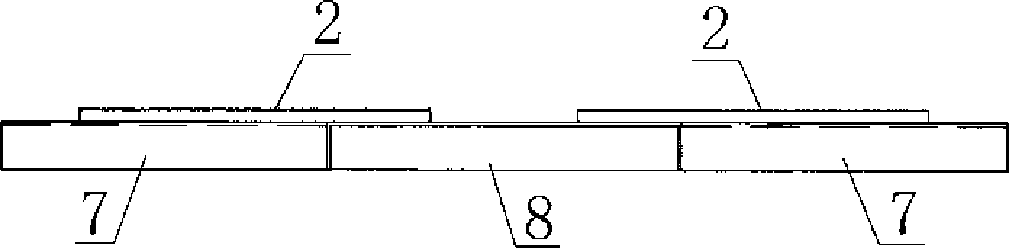

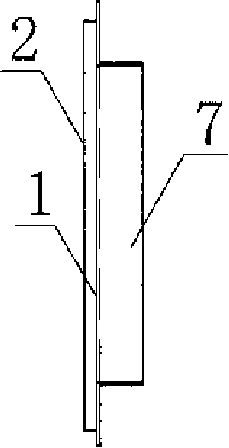

[0033] figure 1 , 2 , 3, and 5 show a typical metal V-shaped embodiment, which is a V-shaped stamped by cold-rolled or hot-rolled thin steel plate or steel strip with a thickness of 0.6-6.0mm (generally 0.8-2.0mm) Integral connectors, the outer edges of the two limb webs 1 have outer flange flanges 7, the inner edges of the two limb webs have inner flange flanges 8, and the cross-sections of the two limb webs are C-shaped; The upper end of the limb forms two upper node planes 3, and the upper node plane 3 has an upper screw hole 4, and the lower ends of the two limbs meet to form a whole lower node plane 5, and the lower node plane 5 has a lower screw hole 6, and the screw hole Various distances should meet the specification requirements. The corners of the upper node plane 3 and the lower node plane 5 form a right angle or an arc angle.

[0034] There are left and right symmetrical indentations in the middle of the abdominal rods of the two limbs, and each limb may have 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com