Method for preparing novel nylon 12 composite material

A composite material, nylon technology, applied in the field of preparation of new nylon 12 composite materials, can solve the problems of complex process, low efficiency, pollution, etc., and achieve the effect of simple process, high efficiency and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

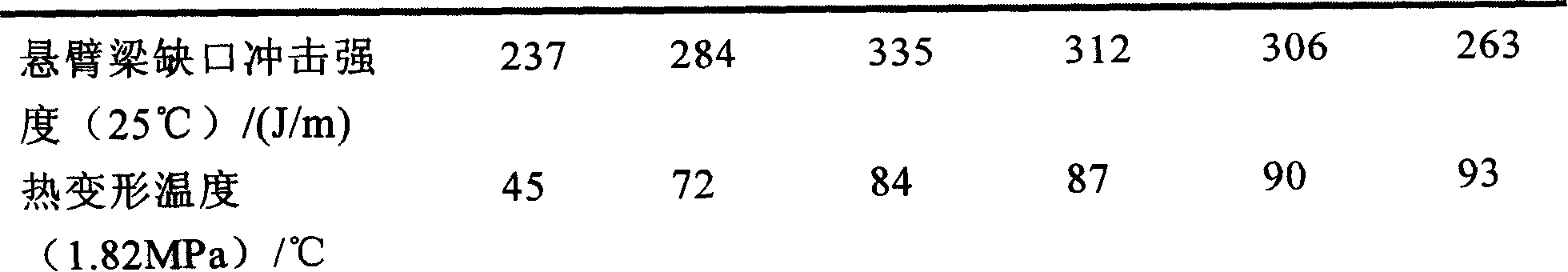

[0019] The content of montmorillonite is 0.5%, the content of maleic anhydride grafted polypropylene is 20%, the content of laurolactam is 77.9%, the initiator is 0.8%, and the activator is 0.8%. Mix the above materials evenly in the mixer Finally, through twin-screw extrusion, the screw temperature is controlled at 200-250°C. The performance of the prepared nylon 12 / polyolefin / montmorillonite composite material is shown in attached table 1

Embodiment 2

[0021] With embodiment 1, montmorillonite content is 1%, the content of maleic anhydride grafted polypropylene is 20%, initiator 0.5%, activator 0.5%, the performance of the nylon 12 / polyolefin / montmorillonite composite material prepared See Schedule 1

Embodiment 3

[0023] Same as Example 1, the content of montmorillonite is 2%, the content of polyolefin is 20%, the initiator is 2%, and the activator is 2%. The properties of the prepared nylon 12 / polyolefin / montmorillonite composite material are shown in attached table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com