Chemical preparing process for flake micron silver powder

A technology of micron silver powder and flake, which is applied in the field of chemical preparation of flake micron silver powder, can solve the problems of poor product performance, complicated process, high energy consumption, etc., and achieve the effect of good crystallization degree, simple preparation process and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1.3 parts by weight of silver nitrate and 18.4 parts by weight of commercially available nitric acid (65-68% in mass concentration) were dissolved in 65.8 parts by weight of water as the bottom solution. 1.3 parts of commercially available L-ascorbic acid (solid) was dissolved in 13.2 parts by weight of water as a reducing solution. Quickly inject the reducing solution into the bottom solution under the condition of stirring; after the addition is completed, stop stirring immediately after the above solution is mixed evenly, and continue to react for 10 minutes. The whole process is carried out at 20±5°C. Then the upper cloudy liquid was poured off. Wash the resulting flaky silver powder with distilled water to neutrality, then wash it with ethanol for one to three times, filter it, and dry it or use other drying methods to dry the product. The scanning electron micrographs of the prepared flake micron silver powder are as follows: figure 1 As shown, the flaky micron...

Embodiment 2

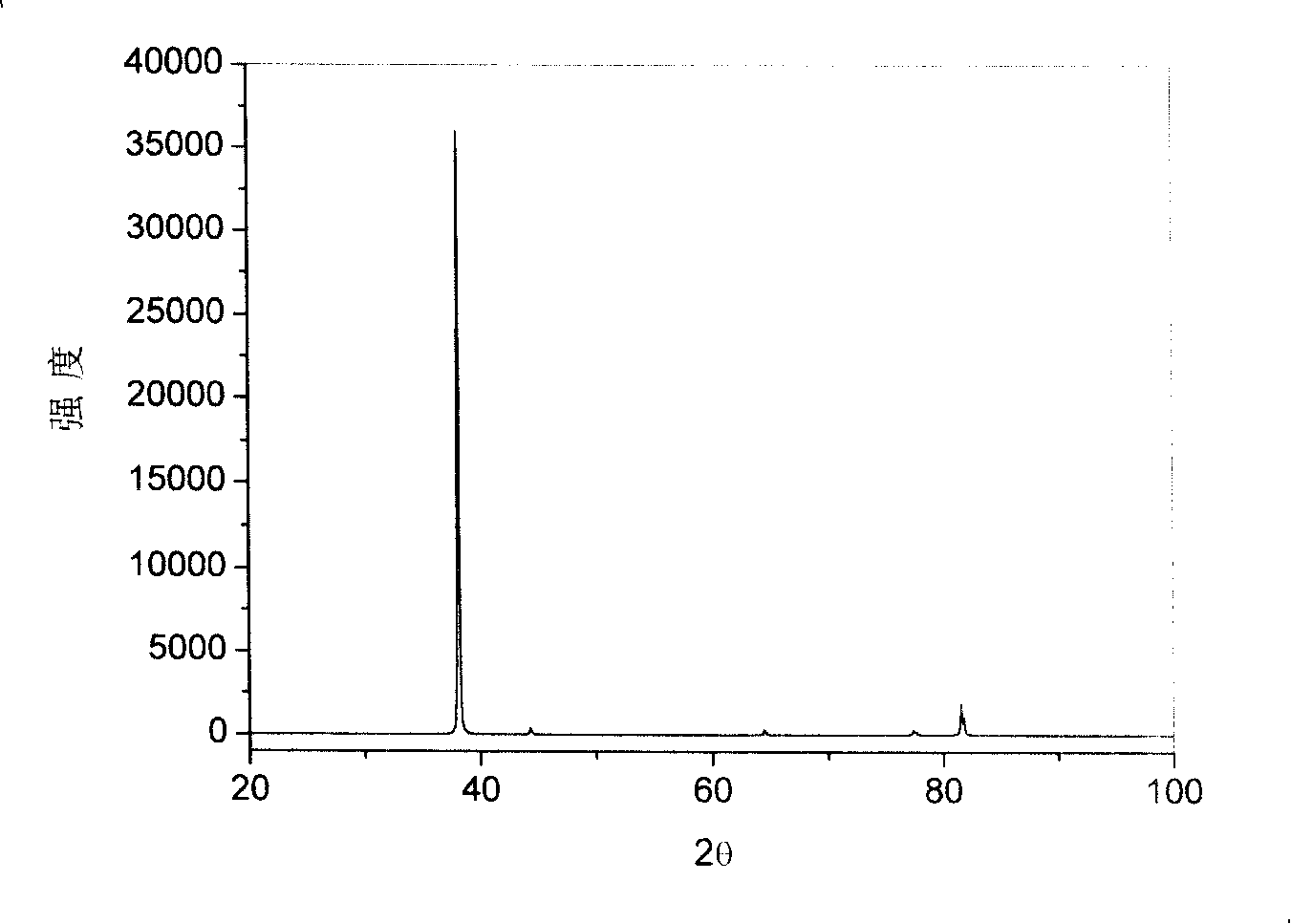

[0034] 1.3 parts by weight of silver nitrate and 11.3 parts by weight of commercially available nitric acid were dissolved in 72.7 parts by weight of water as bottom solution. 1.3 parts by weight of commercially available D-erythorbic acid (solid) was dissolved in 13.4 parts by weight of water as a reducing solution. Under the condition of stirring, quickly inject the reducing solution into the bottom solution; after the addition is completed, stop stirring immediately after the above solution is mixed evenly, and continue to react for 15 minutes. The whole process is carried out at 35±5°C. Then the upper cloudy liquid was poured off. Wash the resulting flaky silver powder with distilled water to neutrality, then wash it with ethanol for one to three times, filter it, and dry it or use other drying methods to dry the product. The granular powder X-diffraction spectrum of the flaky micron silver powder that obtains is as figure 2 As shown, the flaky micron silver powder is ...

Embodiment 3

[0036] 1.8 parts by weight of silver nitrate and 20.3 parts by weight of commercially available glacial acetic acid were dissolved in 58 parts by weight of water as the bottom liquid. 1.5 parts by weight of commercially available L-ascorbic acid was dissolved in 18.4 parts by weight of water; used as a reducing solution. Quickly inject the reducing solution into the bottom solution under the condition of stirring; after the addition is completed, stop stirring immediately after the above solution is mixed evenly, and continue to react for 20 minutes. The whole process is carried out at 15±5°C. Then the upper cloudy liquid was poured off. Wash the resulting flaky silver powder with distilled water to neutrality, then wash it with ethanol for one to three times, filter it, and dry it or use other drying methods to dry the product. The flaky micron silver powder is single crystal, the shape is hexagonal sheet, the average particle diameter of the flaky micron silver powder is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com