Slit nozzle

A slit nozzle and slit technology, applied in the field of slit nozzles, can solve problems such as difficult control of discharge pressure, increased volume, insufficient pressurization, etc., to achieve the effect of eliminating uneven film thickness and reducing idle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

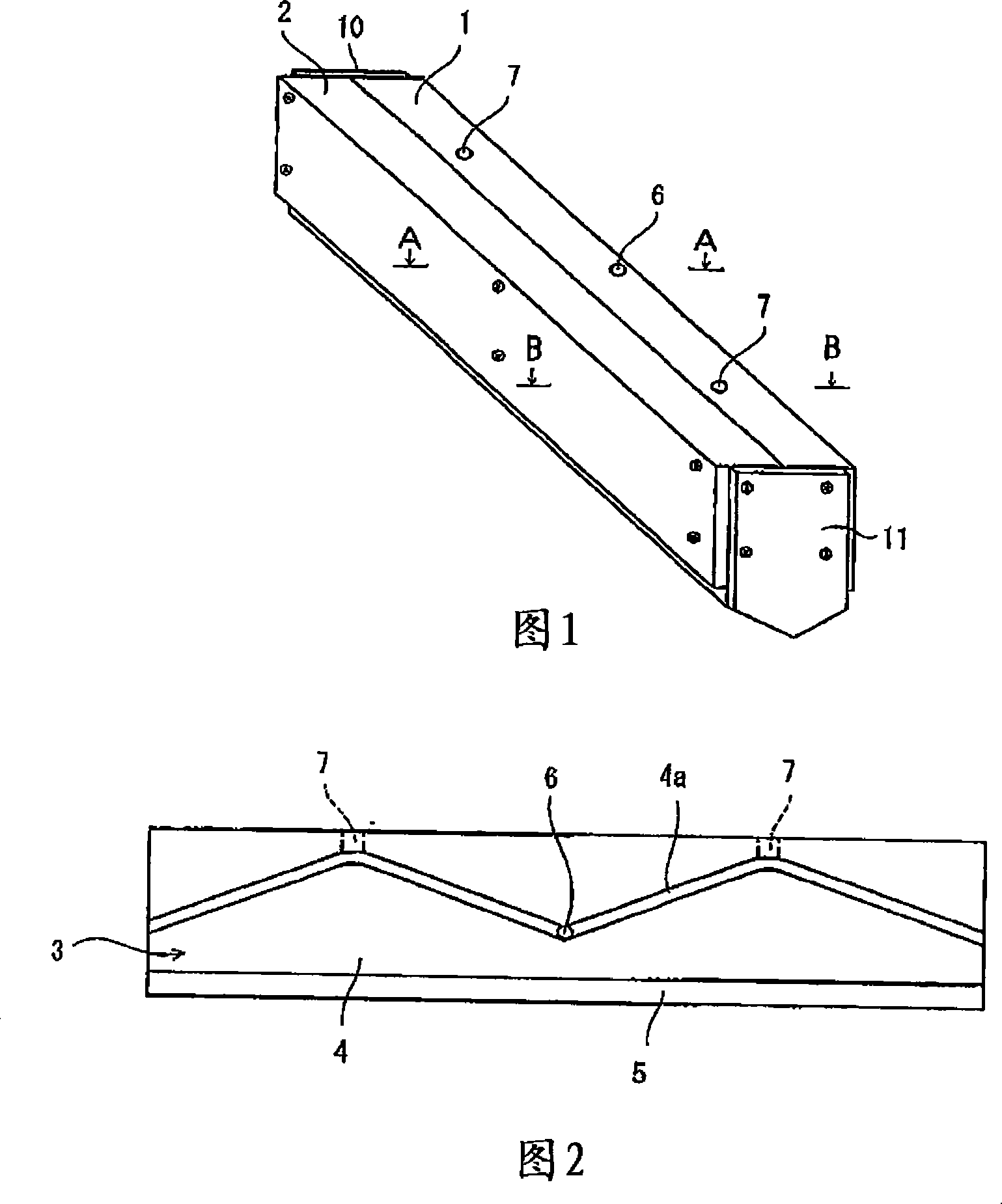

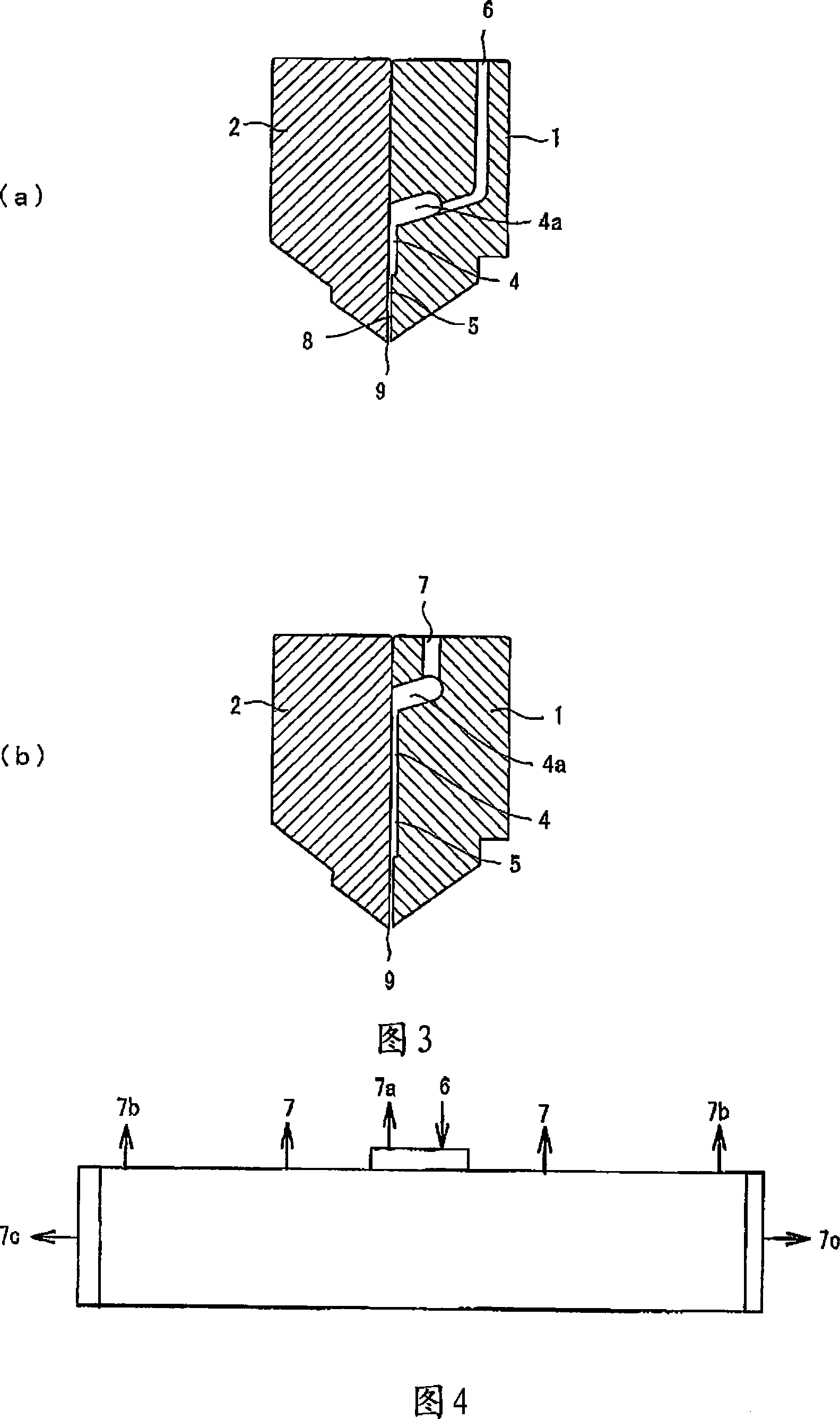

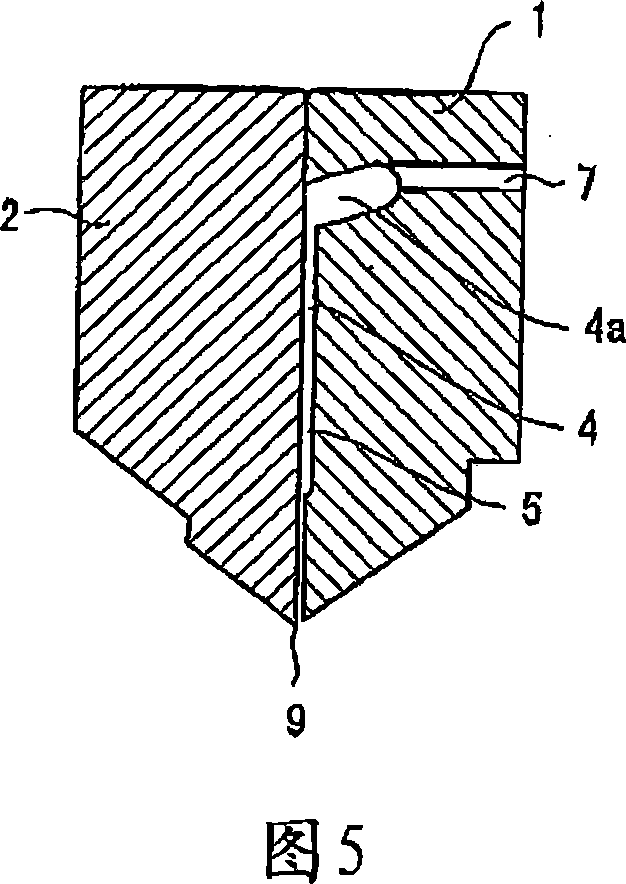

[0024] Hereinafter, preferred embodiments of the present invention will be described based on the drawings. Fig. 1 is the perspective view of the slit nozzle related to the present invention, Fig. 2 is the figure that shows the nozzle half body that constitutes the slit nozzle related to the present invention, Fig. 3 (a) is the sectional view along A-A direction among Fig. 1, ( b) is a cross-sectional view along the B-B direction in FIG. 1 .

[0025] The slit nozzle is formed by butting the left and right nozzle halves 1 and 2 and integrating them with bolts. On the surface of one nozzle half 1 opposite to the nozzle half 2, a coating liquid flow path 3 is formed. The coating liquid channel 3 is formed as a coating liquid channel formed by the first storage part 4 and the second storage part 5 .

[0026] The shed top 4a of the first storage part 4 is pierced to a depth approximately half the size of the nozzle half body 1 in the thickness direction (the left-right direction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com