Drum-type evaporator for making snow and ice

A drum-type, evaporator technology, applied in the field of refrigeration equipment, can solve the problems of large size, slow speed of snow making and ice making, poor snow fineness, etc., and achieve the effect of exquisite appearance, convenient installation and simple production structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

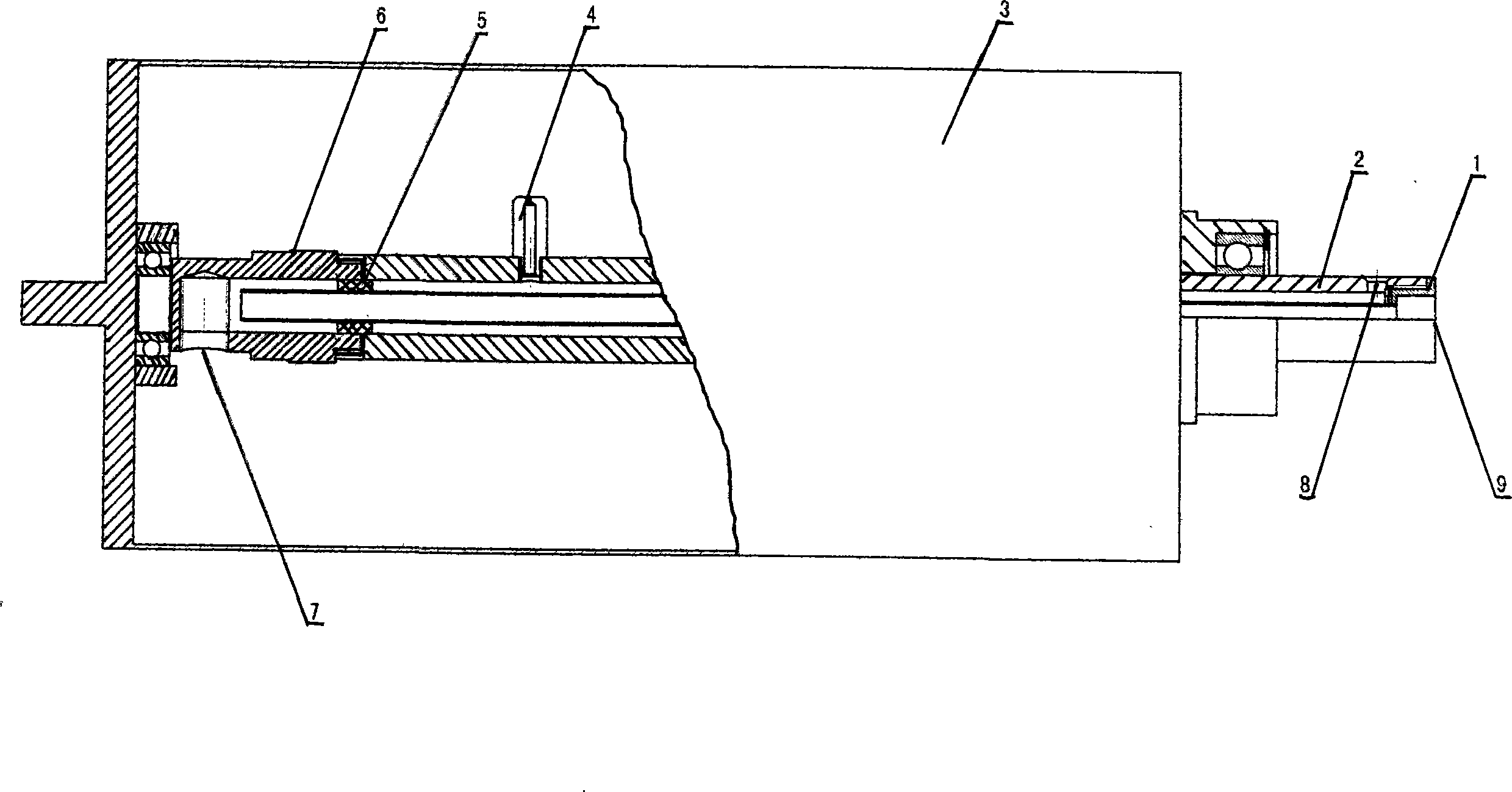

[0013] The drum and the shaft 2 are connected to form a closed and rotatable drum body 3, the right plug 1, shaft 2, nozzle 4, and inner plug 6 are connected as one, and the nozzle 4 and the inner plug 6 can also be retracted and merged with the shaft 2 As an integrated structure, the seal 5 separates the connecting pipe of the right plug 1 and the inner cavity of the shaft 2 into two independent sealing chambers.

[0014] When energized and working, the high-temperature and high-pressure gas compressed and discharged by the compressor is cooled by the condenser, and then passes through the dry filter. The high-pressure refrigerant liquid flows into the shaft 2 through the liquid inlet 8, and passes through the nozzle 4, and the flow is divided into low-pressure and low-temperature ones. The steam is sprayed on the inner wall of the drum body 3 to absorb heat and cool down, so that the filtered water in direct contact with the outer surface of the drum body 3 is rapidly cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com