Double arm type robot

A robot and dual-arm technology, applied in the field of robotics, can solve problems such as the defects of dual-arm robots, the inclination of the center of gravity of the hand joint 140, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

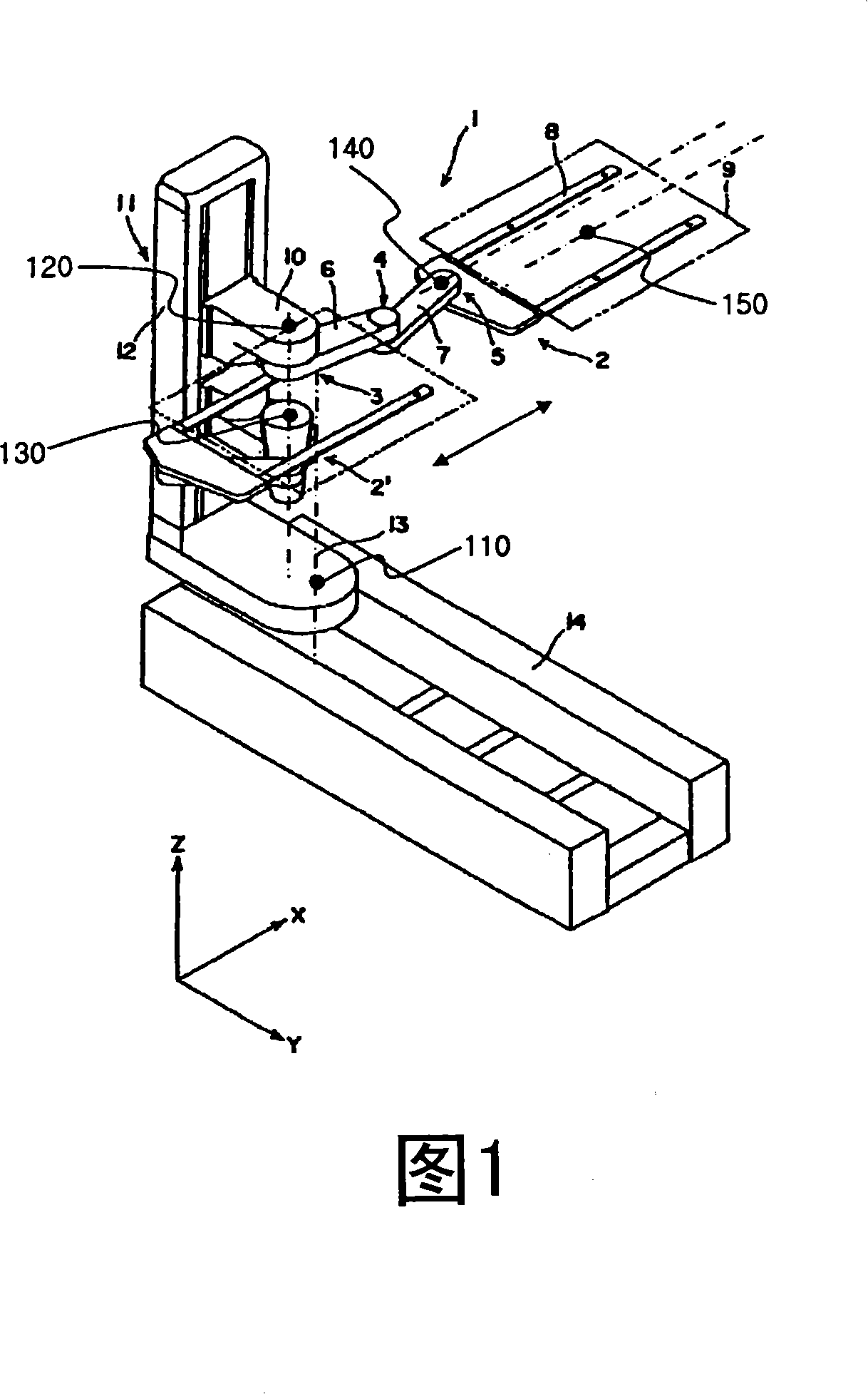

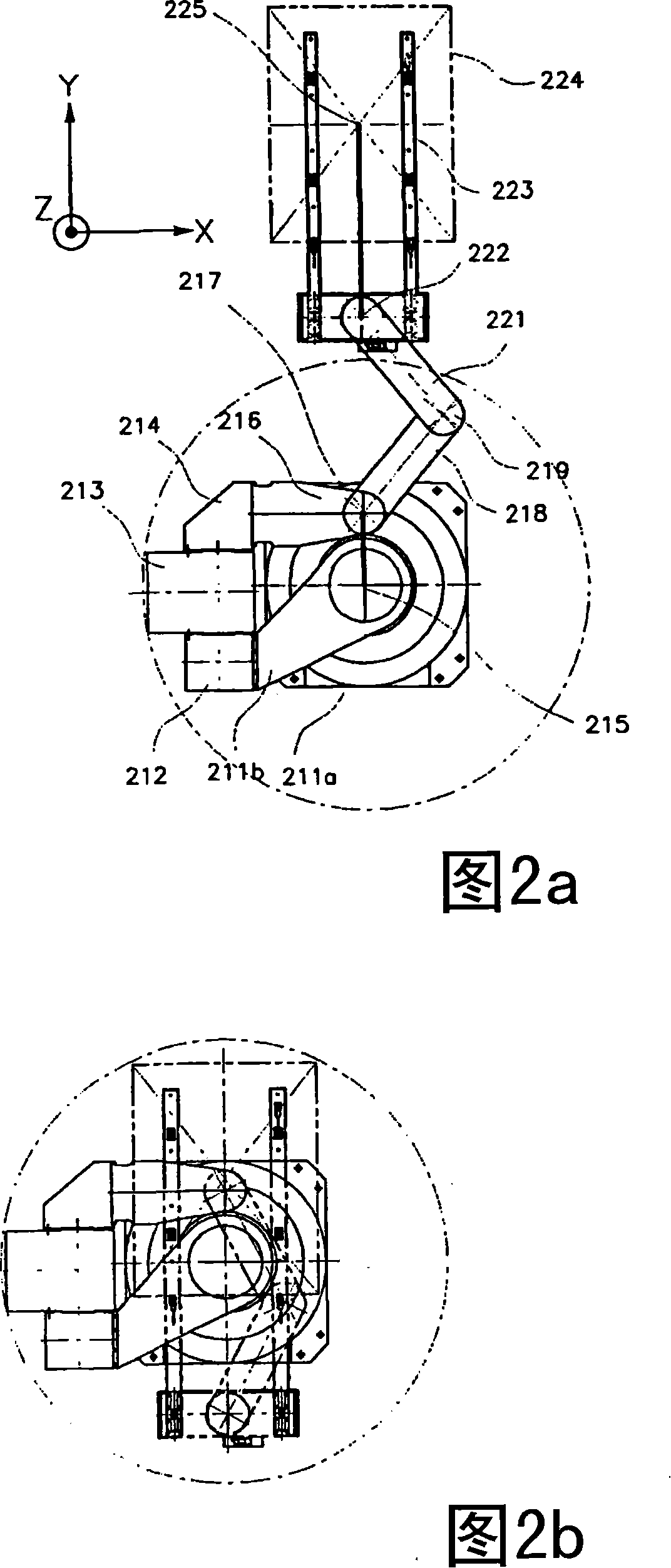

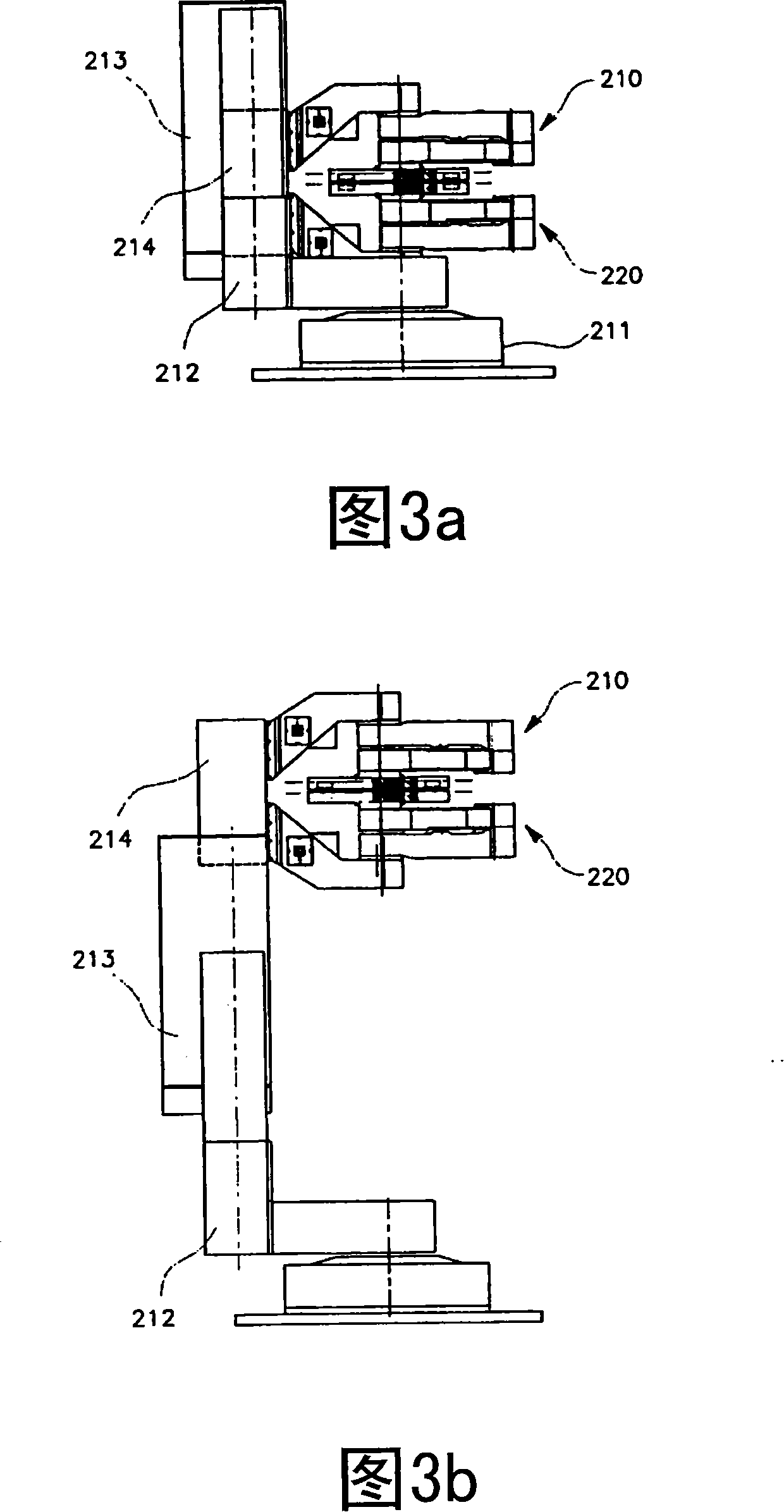

[0034] The dual-arm robot according to the first embodiment of the present invention will be described in detail with reference to FIGS. 2 and 3 .

[0035] 2 is a top view showing the dual-arm robot according to the first embodiment of the present invention, FIG. 2a is a top view when both arms are in an extended position, and FIG. 2b is a top view when both arms are in a retracted position.

[0036] The dual-arm robot has a first arm 210 arranged at the top and a second arm 220 arranged at the bottom.

[0037] The dual-arm robot includes two sets of arms 210 and 220 that are rotatably connected by joints 217 , 219 , and 222 and that transmit rotational force from a rotational drive source (not shown) to perform operations.

[0038] The dual-arm type robot has two sets of robotic arms 210 and 220, one of which is used for feeding and the other is used for taking out, thereby performing the feeding operation and the taking-out operation of the workpiece 224, or is configured to...

no. 2 example

[0050] The second embodiment of the present invention is another embodiment capable of obtaining the same effect as the first embodiment, except that the positions of the rotation centers of the knee joints of the first robot and the second robot are different from those of the first embodiment, and other The structures are all the same.

[0051] 4 is a top view showing a dual-arm robot according to a second embodiment of the present invention, FIG. 4a is a top view when both arms are in an extended position, and FIG. 4b is a top view when both arms are in a retracted position. Refer to Figure 3 for the side view.

[0052] The double-armed robot has a first mechanical arm 210 disposed on the upper part and a second mechanical arm 220 disposed on the lower part, and is connected to be rotatable by joints 417a, 417b, 419a, 419b, 422a, 422b and transmitted by a rotational drive source. (not shown) generates rotational force and performs actions.

[0053] The dual-arm type robot...

no. 3 example

[0064] The third embodiment of the present invention is another embodiment capable of obtaining the same effects as those of the first embodiment, except that the positions of the rotation centers of the knee joints of the first robot and the second robot are different from those of the first embodiment. , all other structures are the same.

[0065] 5 is a top view showing a dual-arm robot according to a third embodiment of the present invention, FIG. 5a is a top view when both arms are in an extended position, and FIG. 5b is a top view when both arms are in a retracted position. Refer to Figure 3 for the side view.

[0066] The dual-arm robot has a first mechanical arm 210 disposed on the upper part and a second mechanical arm 220 disposed on the lower part, and is connected to be rotatable by joints 515a, 515b, 519a, 519b, 522a, 522b and transmitted by a rotational drive source. (not shown) generates rotational force and performs actions.

[0067] The dual-arm type robot h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com