Mandrel of printing equipment, printing cylinder and printing equipment

A technology for printing cylinders and printing equipment, applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of complex compression gasket structure, limited clamping force, etc., and achieve improved total indication deviation and high throughput speed , good printing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the present application, similar or corresponding features are indicated by similar or corresponding reference numerals. The description of various embodiments is not limited to the examples shown in the drawings, and reference numerals used in the detailed description are not intended to limit the description of the embodiments. Reference numerals are included to clarify the embodiments by referring to the examples shown in the figures.

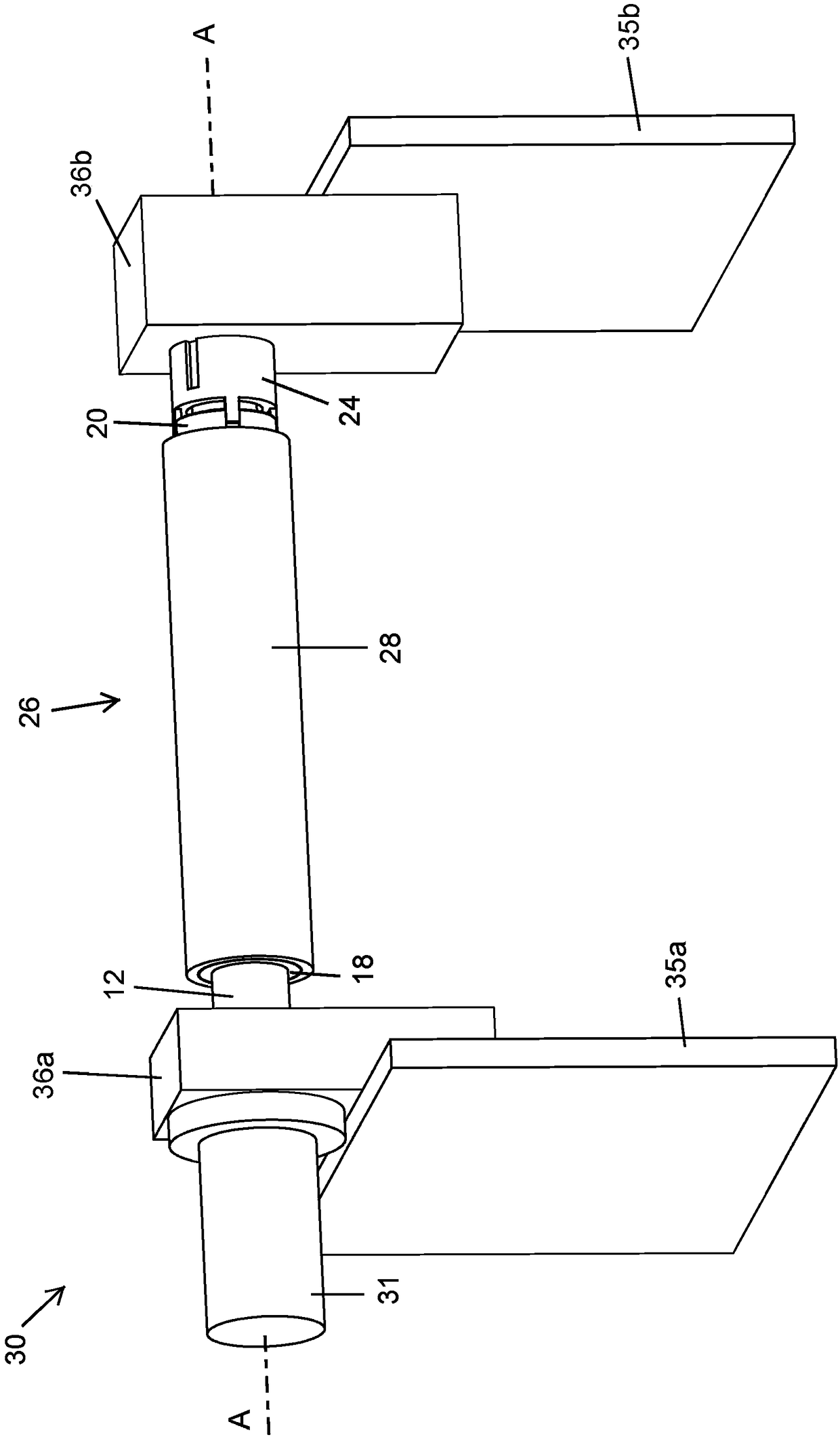

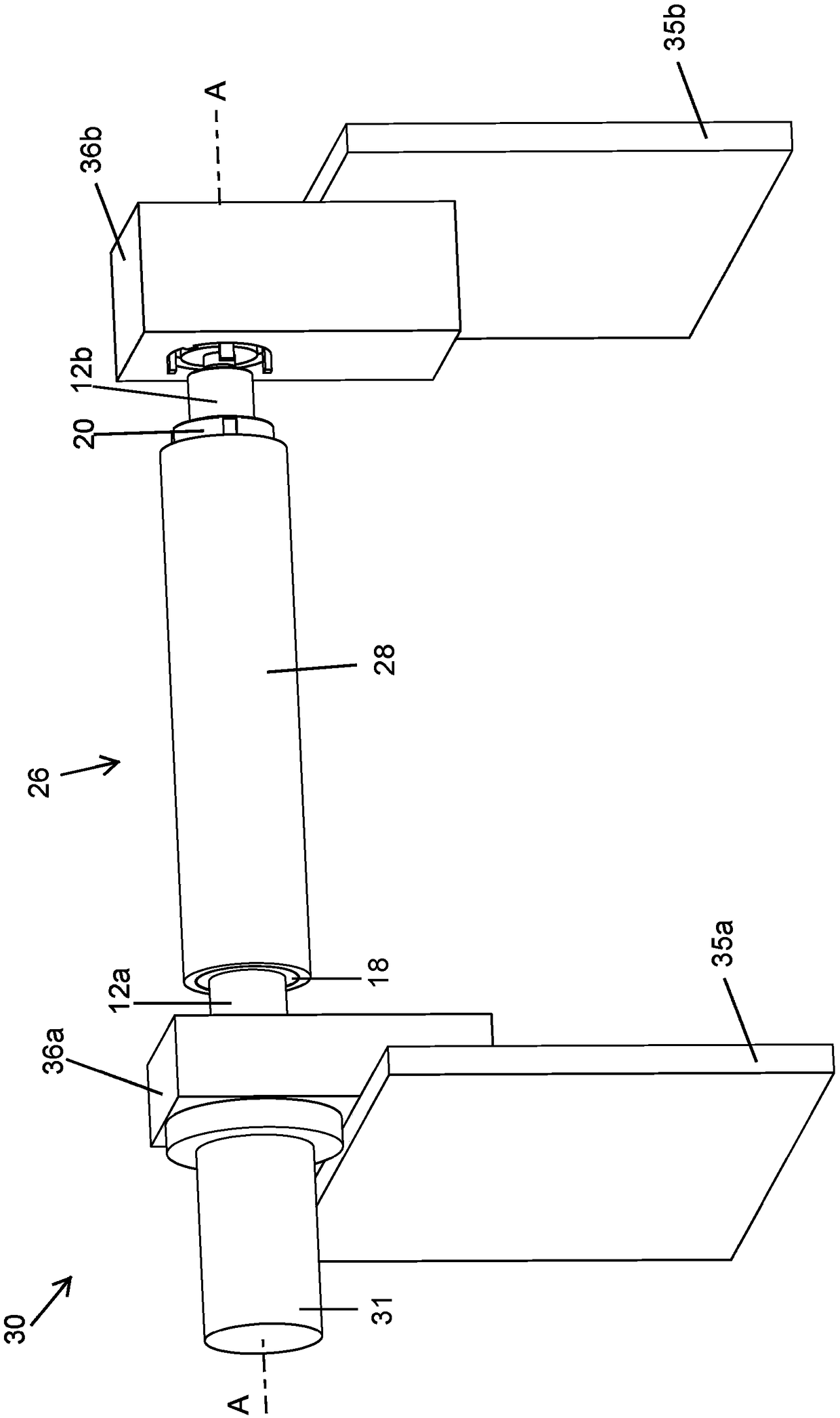

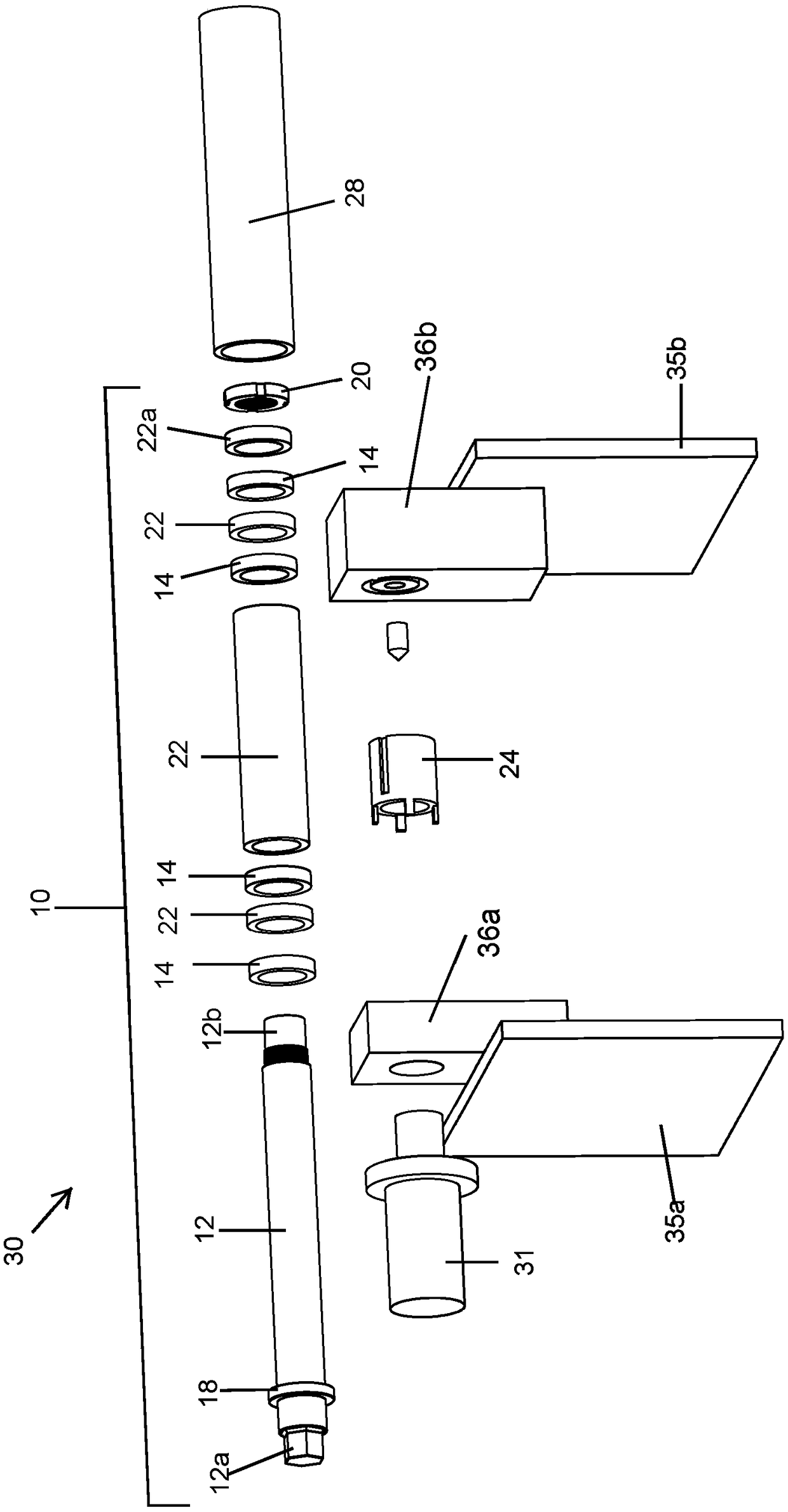

[0046] Broadly, the mandrel 10 includes a generally cylindrical mandrel shaft 12 extending along a mandrel axis A and a plurality of expandable rings 14 slidably and coaxially mounted on the mandrel shaft 12 . Each expandable ring 14 expands radially outward when the expandable rings 14 are axially compressed. The mandrel 10 also includes a locking assembly comprising a stop ring 18 having an axially fixed position on the mandrel shaft 12 adjacent the first end 12a of the mandrel shaft 12, and a locking ring 20 for locking Ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com