Air cleaner of engine and air cleaner mounting device for mounting air cleaner on engine

A technology of air filter and installation device, which is applied in the direction of fuel air filter, combustion air/combustion-air treatment, engine components, etc., which can solve the problem of increased air filter cover and difficulty in ensuring air filter support Rigidity, low efficiency of fastening work, etc., to achieve the effect of improving the support rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

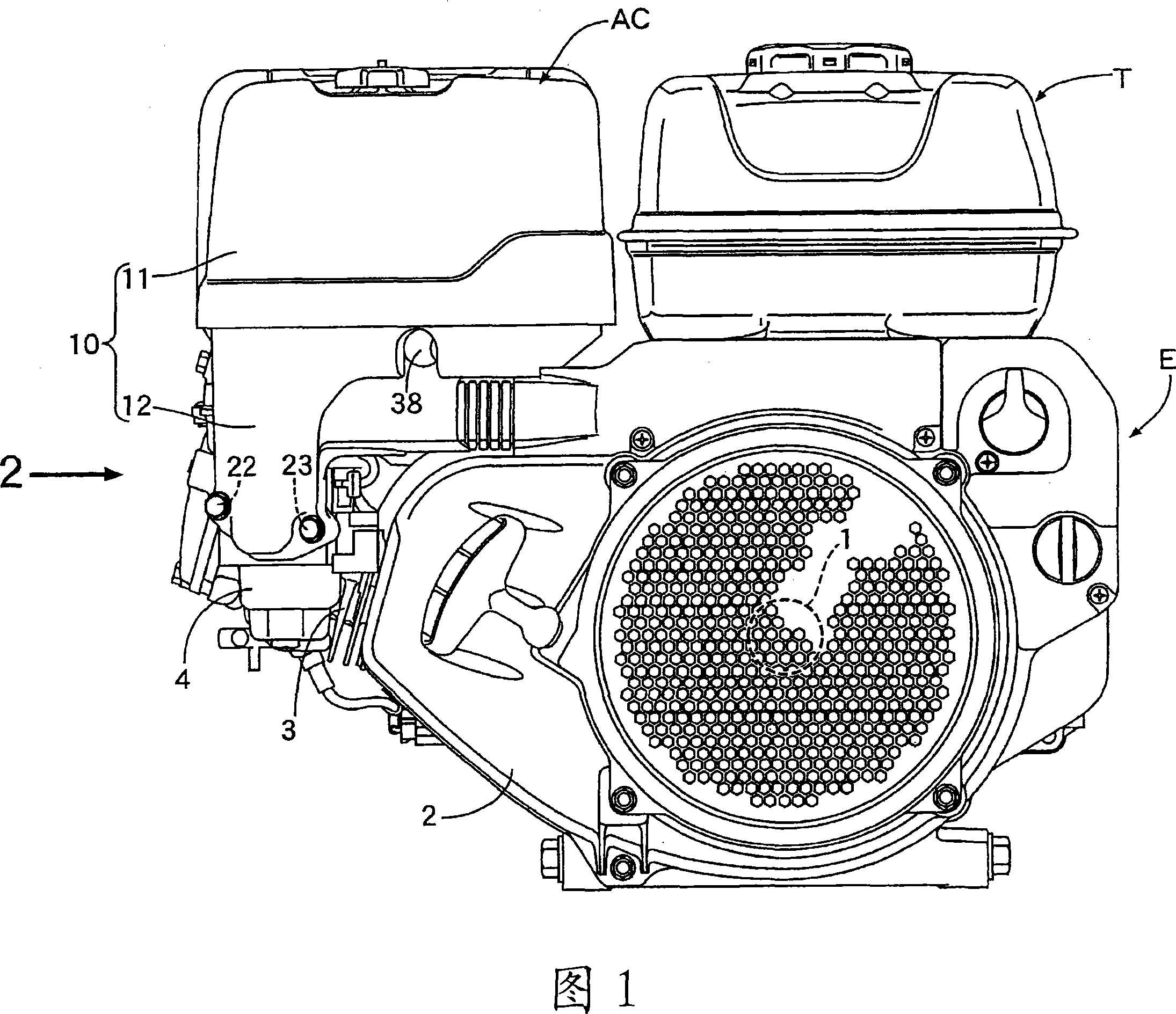

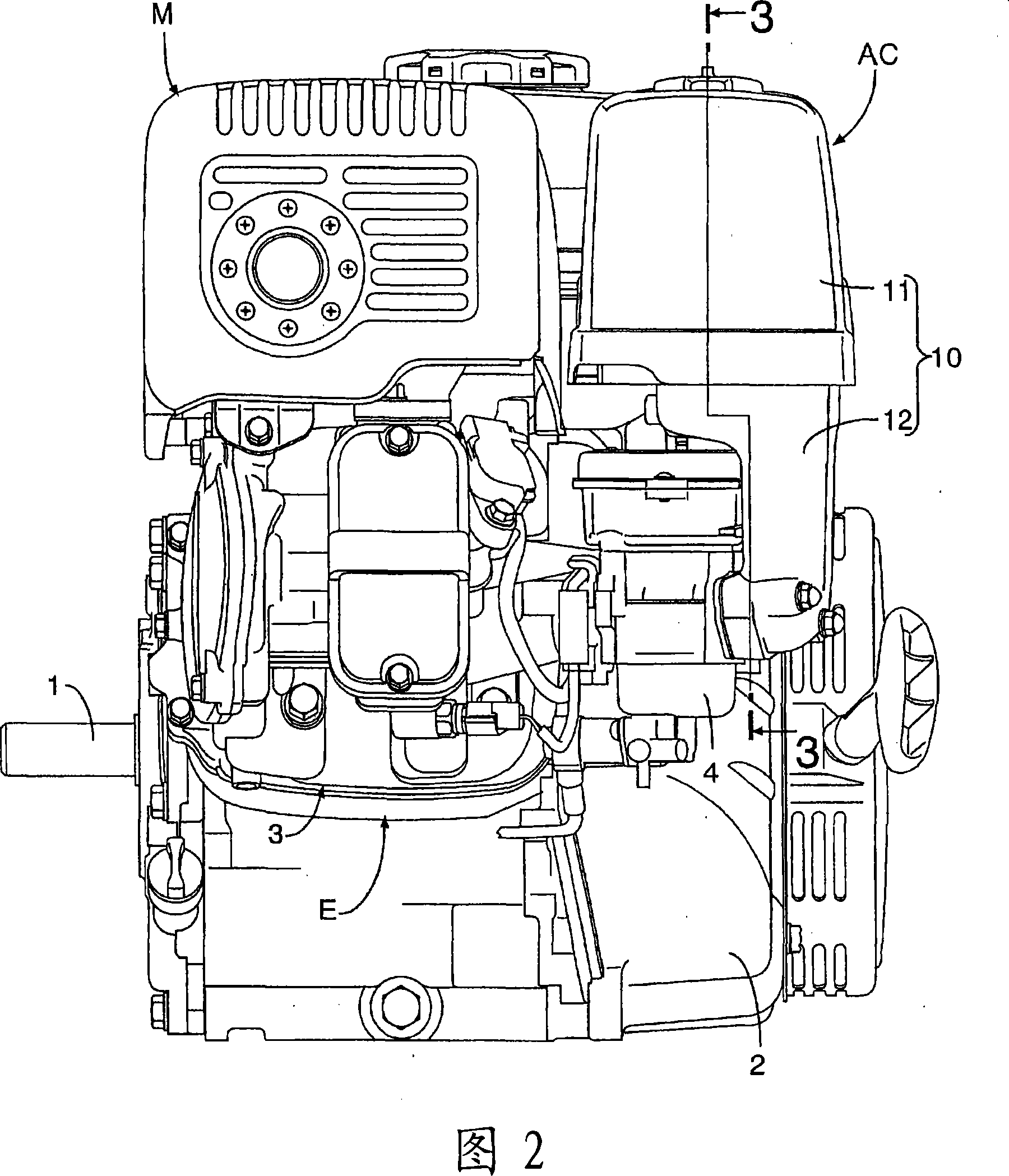

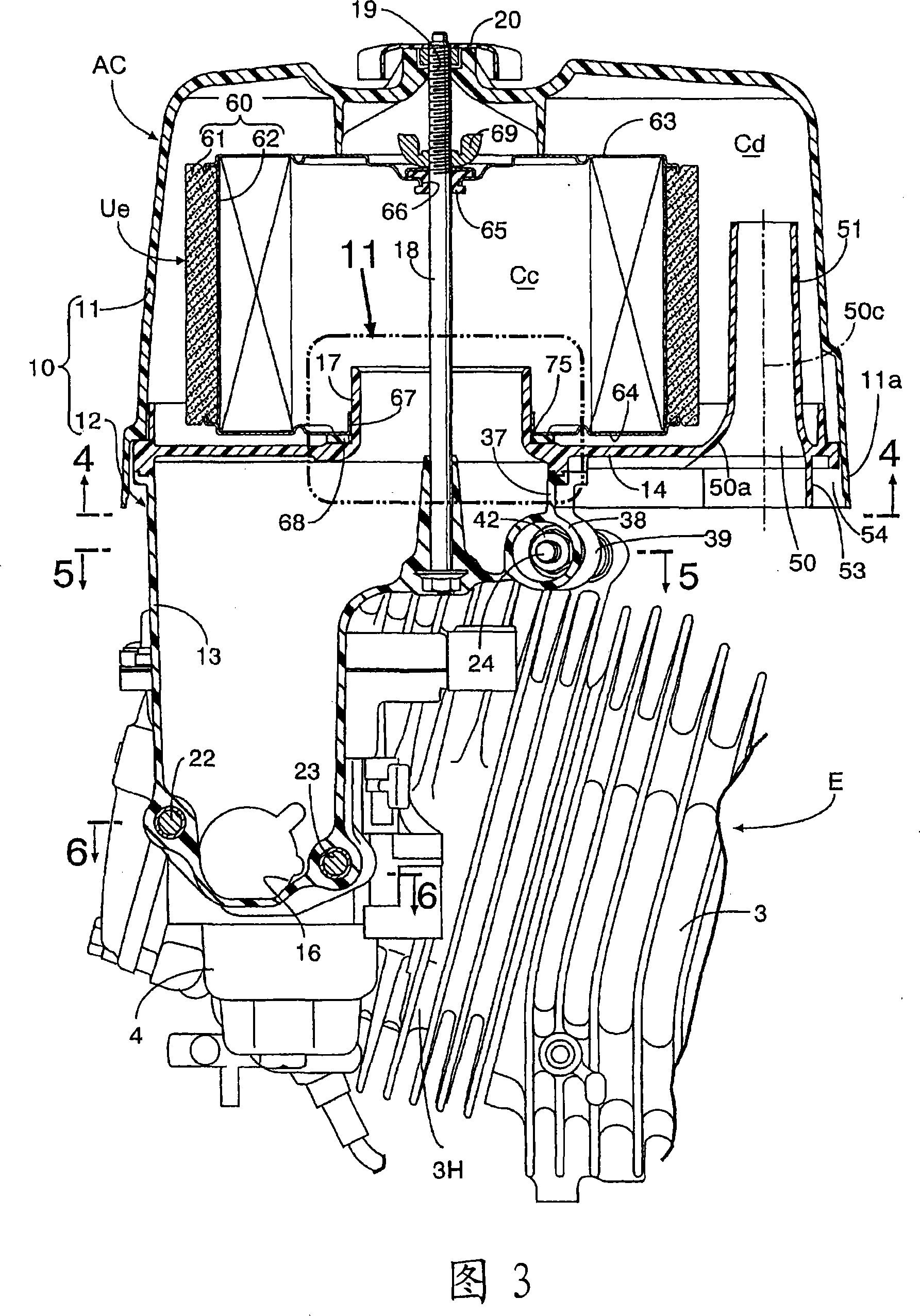

[0091] First, refer to Figures 1 to 11 A first embodiment of the present invention will be described.

[0092] exist figure 1 , 2 Among them, the general-purpose engine E serving as a power source of various working machines in the general-purpose engine unit is a four-stroke engine, and the general-purpose engine E has a crankcase 2 supporting a crankshaft 1 arranged in the horizontal direction and a crankcase 2 extending obliquely upward from the crankcase 2. The protruding cylinder part 3 is provided with a fuel tank T supported thereon directly above the crankcase 2. In addition, a carburetor 4 is installed on one side of the cylinder part 3. The air filter connected to the carburetor 4 The cleaner AC and the exhaust muffler M connected to the other side of the cylinder unit 3 are arranged on the side of the fuel tank T and directly above the cylinder unit 3 .

[0093] Refer below Figure 1 to Figure 11 The structure of the air cleaner AC of this invention is demonstr...

no. 2 example

[0118] Refer below Figures 12 to 14 A second embodiment of the present invention will be described.

[0119] This second embodiment is slightly different from the above-mentioned embodiments in the following respects: a sealing gasket made of a rubber gasket is interposed between the upper surface of the partition wall 14 and the lower surface of the lower plate 64 of the filter element unit Ue 268 and the structure of its installation part. The seal packing 268 is formed in a square ring shape, and is fitted on the base outer peripheral surface of the square tube-shaped intake passage 17 in the same manner as in the first embodiment described above. On the middle part of the width direction of the upper sealing surface 271 and the lower sealing surface 273 of the above-mentioned sealing gasket 268, upper and lower lips 272, 274 with a triangular cross section protrude integrally, and the upper lip 272 is in close contact with the filter element unit. Ue is on the lower sur...

no. 3 example

[0123] Refer below Figures 15 to 17 A third embodiment of the present invention will be described.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com