On-line tension force detecting mechanism

A technology of tension detection and tension sensor, which is applied in the direction of tension measurement, length measuring device, metal rolling, etc., can solve the problem of low relative control accuracy, and achieve the effect of good tension optimization, accurate calculation and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

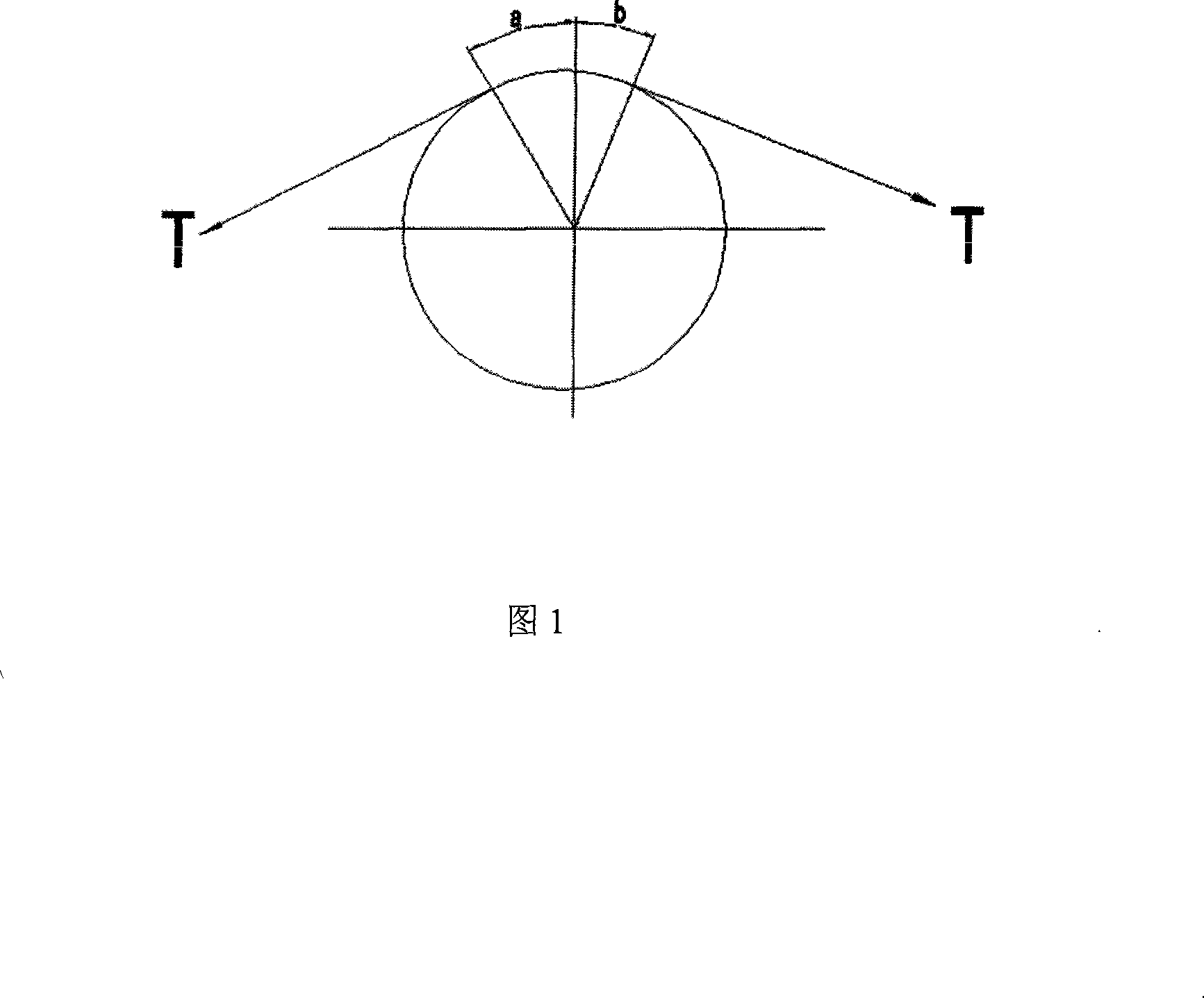

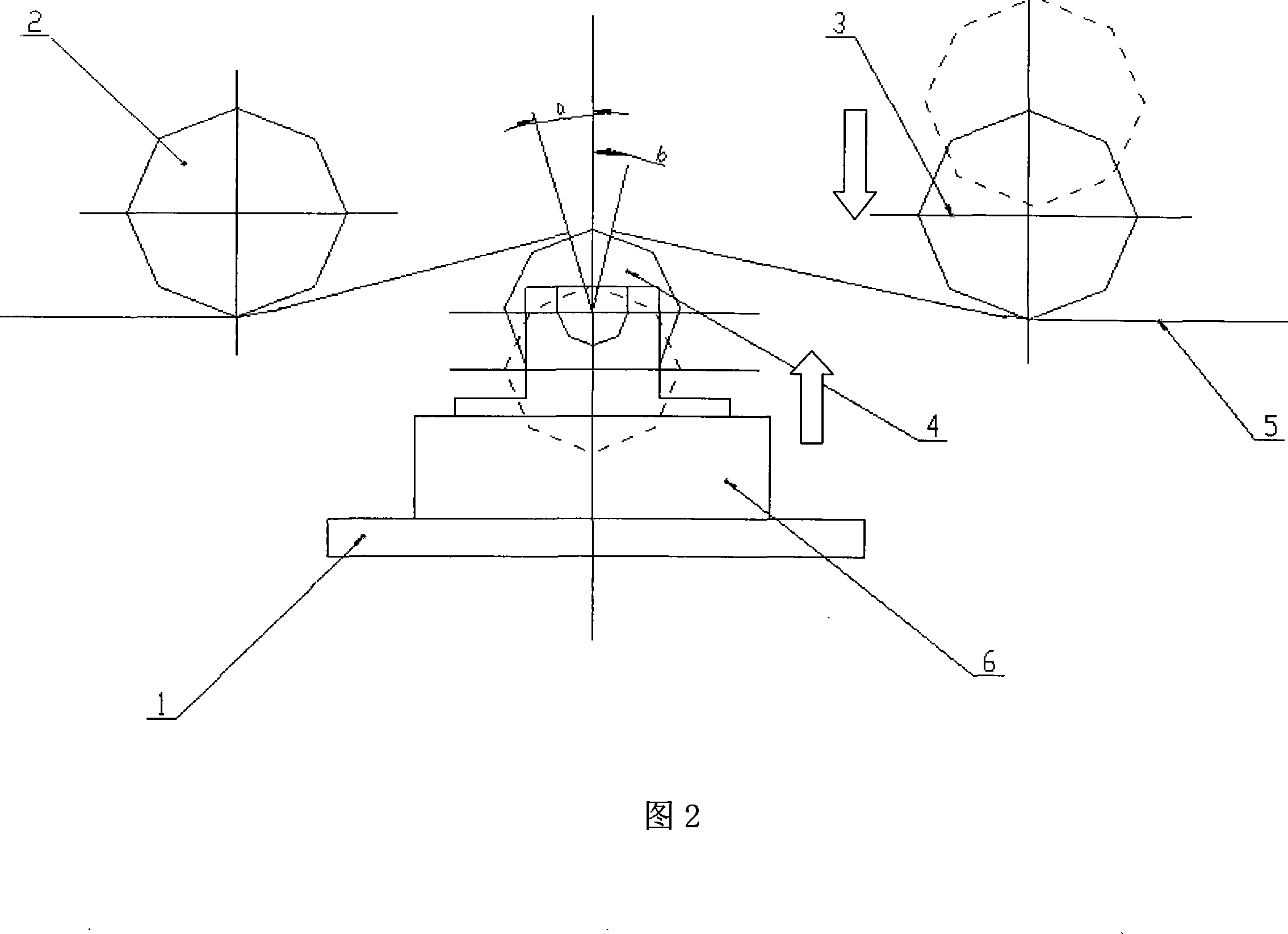

[0012] As shown in Figure 2, the tension measuring roller 4 is fixed on the oil cylinder base 1 with lifting function, and the tension measuring roller 4 is located between the fixed roller 2 and the upper anti-wrinkle roller 3 of the hydraulic shear. When the cold-rolled strip 5 is threaded, the tension measuring roller 4 is lower than the steel strip, and the upper anti-crease roller 3 is higher than the position of the steel strip at the same time, that is, the tension measurement roller 4 and the upper anti-crease roller 3 are not in contact with the steel strip. After the belt threading is finished, the tension measuring roller 4 rises to the limit position under the action of the oil cylinder, and at the same time, the upper anti-wrinkle roller 3 rises to the limit position under the action of the oil cylinder. At this moment, the steel strip is in surface contact with the fixed roll 2, the tension roll 4 and the upper anti-wrinkle roll 3, and the cold-rolled strip 5 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com