Molding condition setting method

A technology of condition setting and mold clamping force, which is applied in chemical instruments and methods, transportation and packaging, plastic recycling, etc., can solve the problems of applying mold clamping force, and achieve the control of mold clamping force and high precision mold clamping force The effect of the control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] One embodiment of the present invention will be described with reference to the drawings.

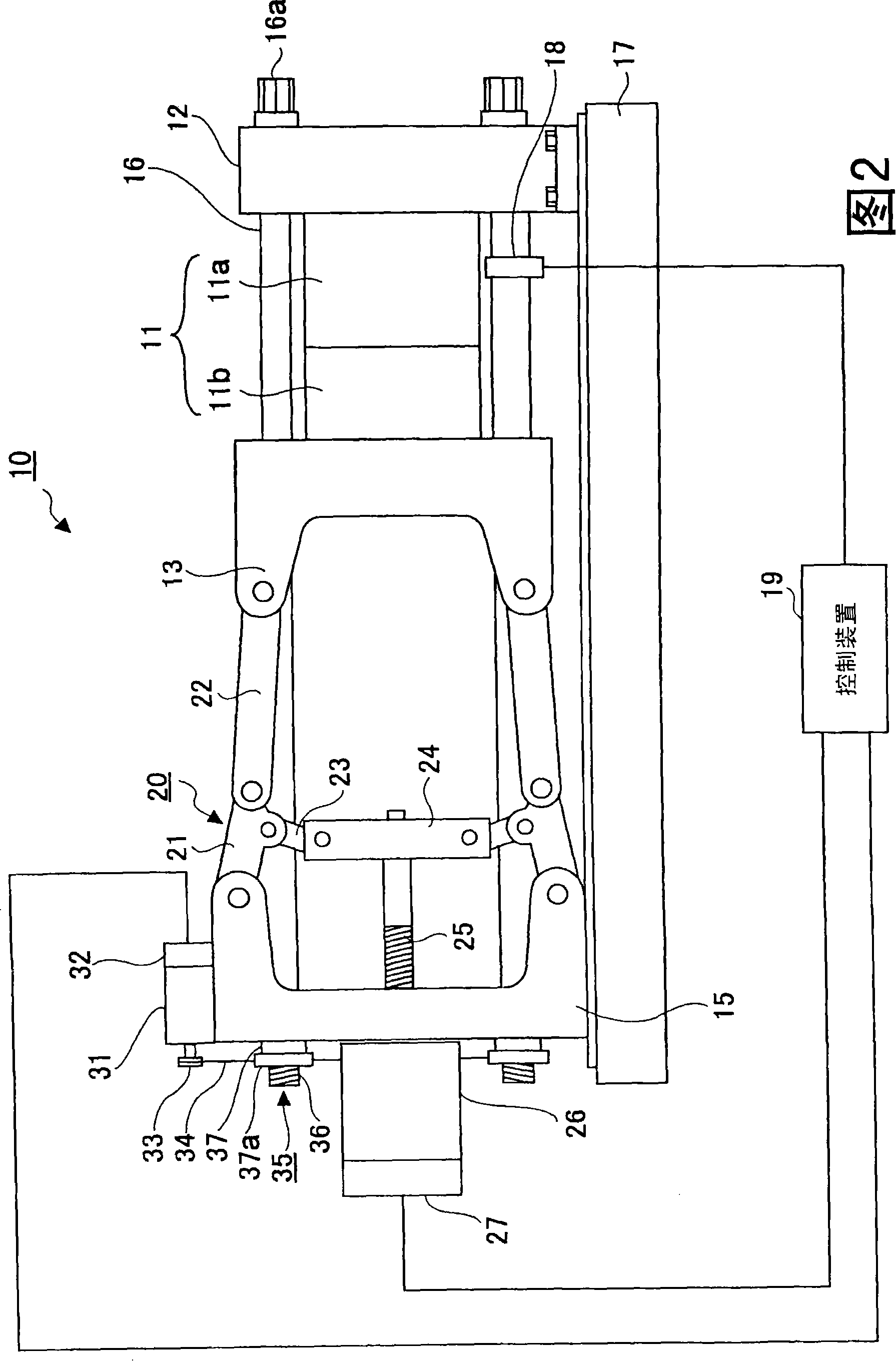

[0041] Fig. 2 is a side view of a mold clamping device of a molding machine for implementing a molding condition setting method according to an embodiment of the present invention. In Fig. 2, the clamping device 10 of the injection molding machine has: a frame body 17; a fixed plate 12 as a fixed mold supporting device fixed on the frame body 17; The substrate is provided so as to move relative to the frame body 17 at a predetermined distance. The toggle support 15 functions as a toggle type mold clamping device support device. Between the fixed plate 12 and the toggle support 15 a plurality of (for example four) connecting rods 16 as guide units extend.

[0042] The movable plate 13 is provided facing the fixed plate 12, and functions as a movable mold supporting device provided so as to be able to move forward and backward (movable in the left-right direction in the figure) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com