A sealing technology and device for separation film bag

An edge-sealing device and membrane bag technology, applied in the direction of structural parts, electrical components, battery pack parts, etc., can solve problems such as trouble, insufficient strength, troublesome variety replacement, etc., and achieve simple device structure, small edge width, and difficult The effect of the rift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

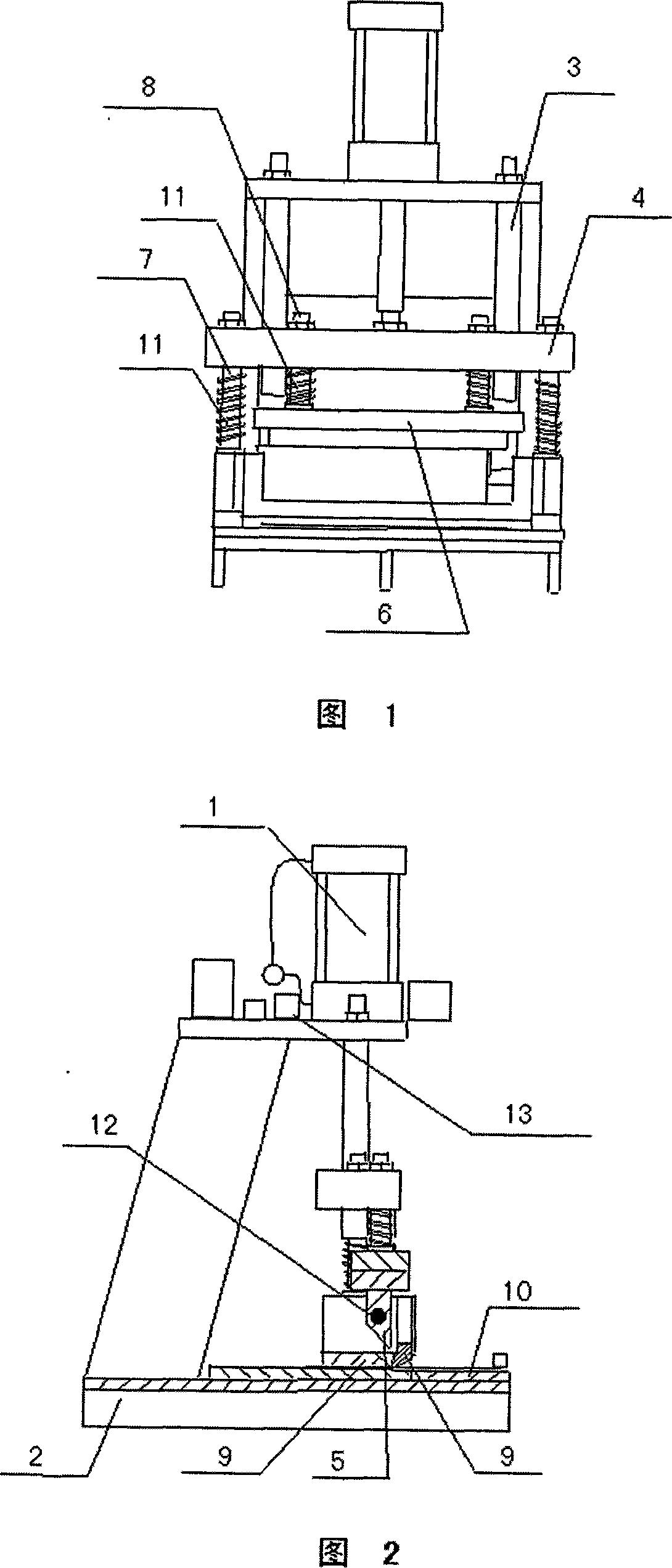

[0026] According to Fig. 1, Fig. 2 shows, a kind of edge banding device of membrane bag, it comprises cylinder 1 and base 2, is provided with guide rod 3, guide rod fixing plate 4, electric heating knife 5 between described 1 cylinder and base 2 , electric heating knife fixed plate 6, pressing plate guide rod 7, electric heating knife guiding rod 8, two pressing plates 9 and backing plate 10. The cylinder base body is provided with a guide rod 3 passing downward through the guide rod fixed plate 4, and when the guide rod fixed plate 4 moves, it slides along the guide rod 3 to prevent horizontal rotation of the guide rod fixed plate 4 when moving.

[0027] The lower end of the cylinder push rod is connected with the guide rod fixed plate 4, and the guide rod fixed plate 4 is connected with a pair of electric knife guide rods 8 and a pair of pressure plate guide rods 7, and two pressure plates 9 are fixed at the lower ends of the two pressure plate guide rods 7, There is a gap o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com