A cable peeling device

A cable and cable hole technology, which is applied in the field of devices where the skin and core are separated, can solve the problems of hurting people, not easy to cut, thick cable skin, etc., to ensure safety, prevent cable deviation, and fast peeling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

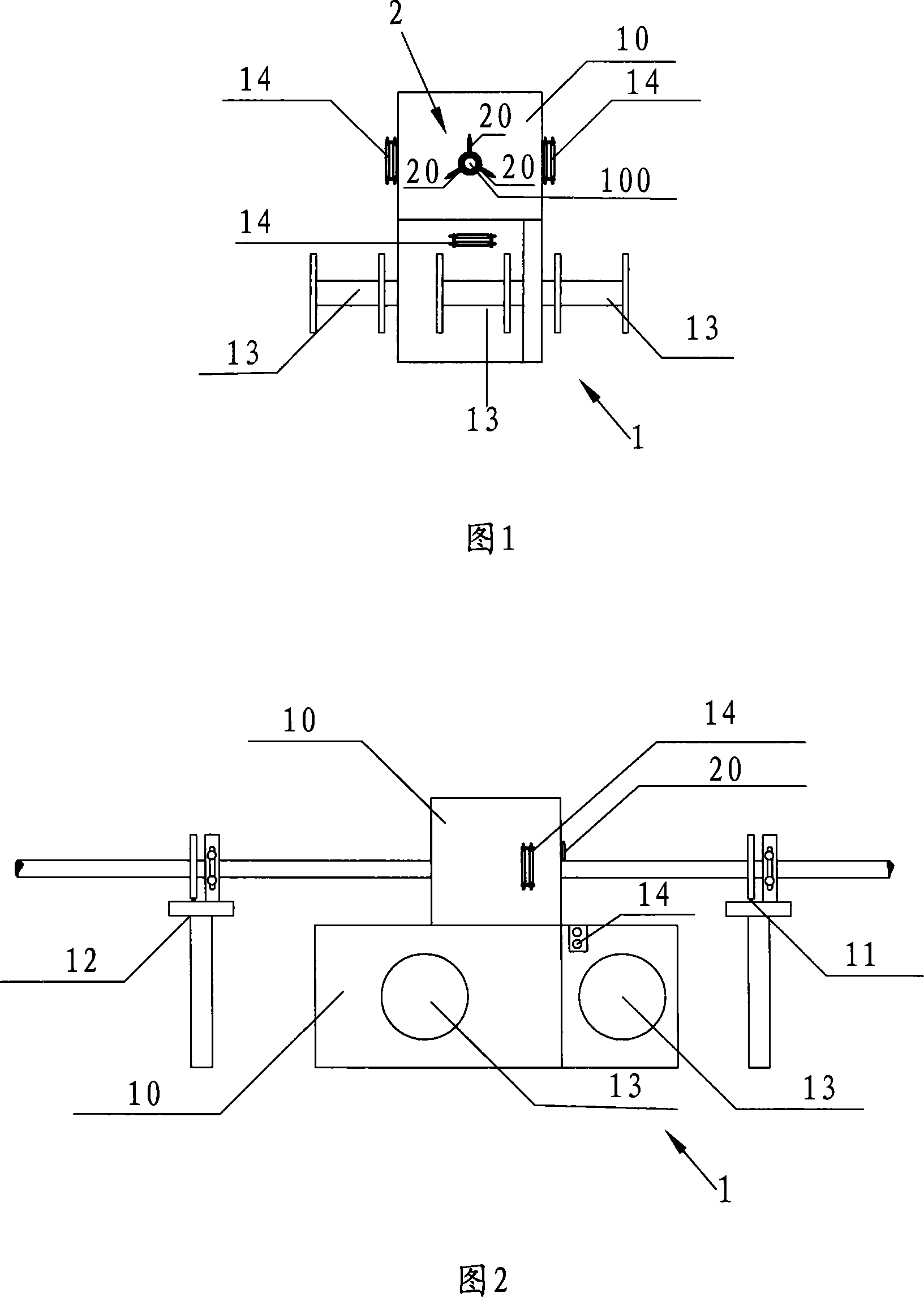

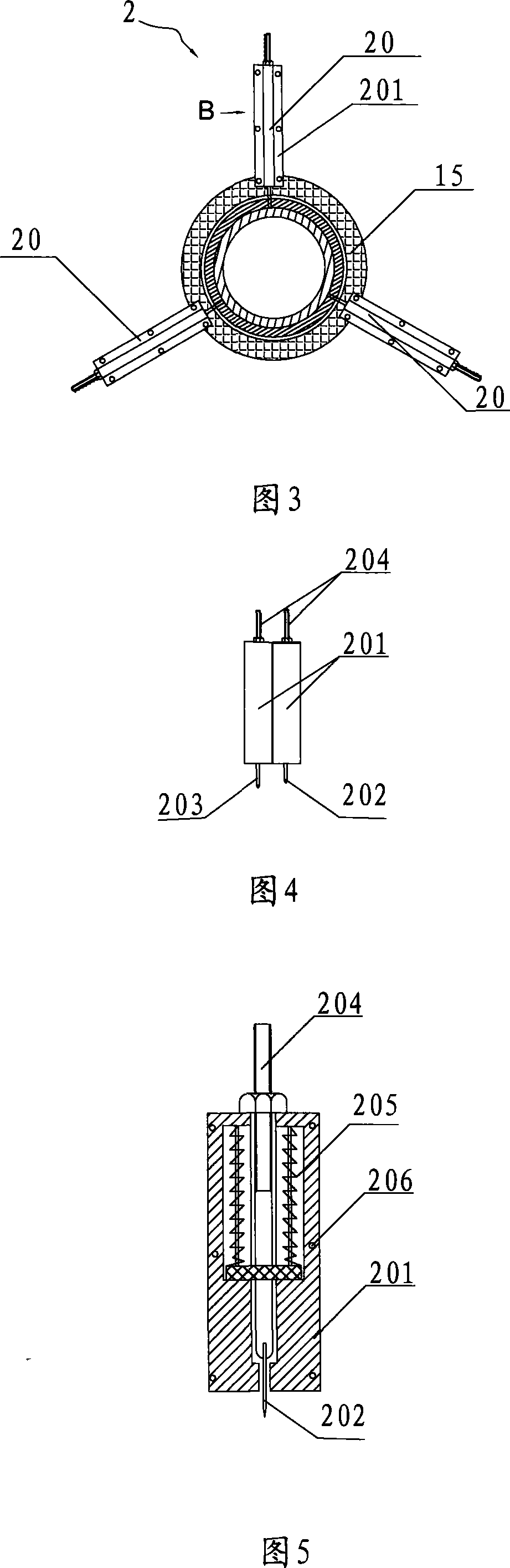

[0018] Referring to Figs. 1 to 5, the cable stripping device according to this embodiment is mainly composed of a fixing device 1 and a stripping knife 2 arranged on the fixing device 1.

[0019] The fixing device 1 includes a fixing seat 10, a front guide roller 11 and a rear guide roller 12 respectively arranged at the front and rear of the fixing seat 10. The front guide roller 11 and the rear guide roller 12 are used to fix the cable to avoid the bending of the cable. The speed of peeling while obstructing.

[0020] A wire take-up wheel 13 is provided on the left and right sides and the front side of the fixed base 10 respectively, and a motor is provided in the fixed base 10 to drive the wire take-up wheel 13. On the left side, right side, and front side of the fixed seat 10, a "well"-shaped guide roller 14 is respectively provided. The guide rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com