Gear mechanism for a heald shaft drive

A gear mechanism and gear technology, applied to belts/chains/gears, looms, heddles, etc., can solve problems such as different loads of two planetary gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

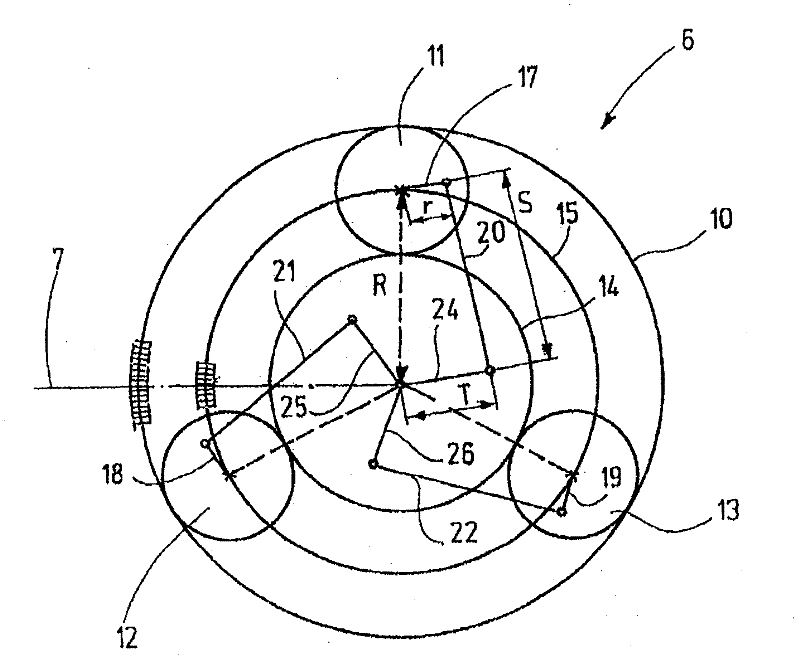

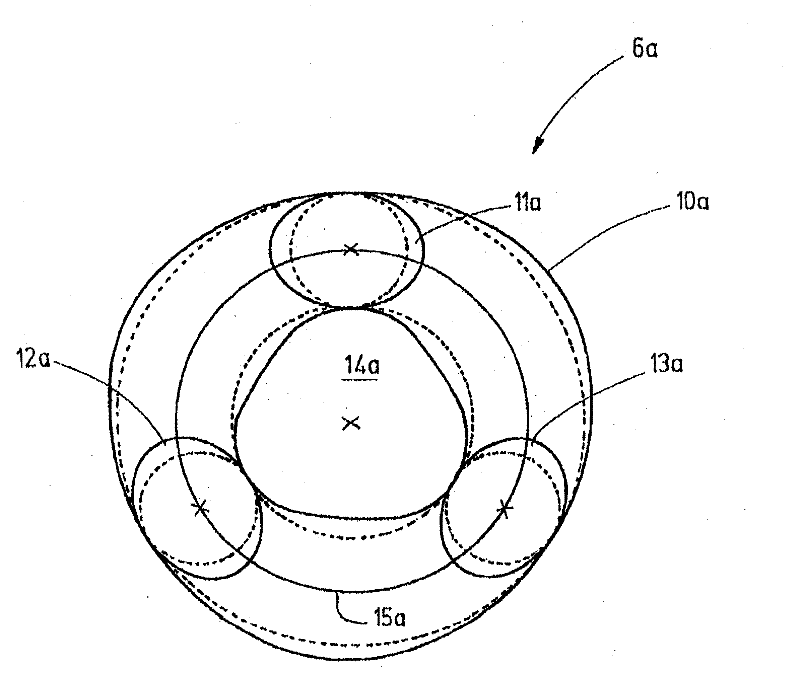

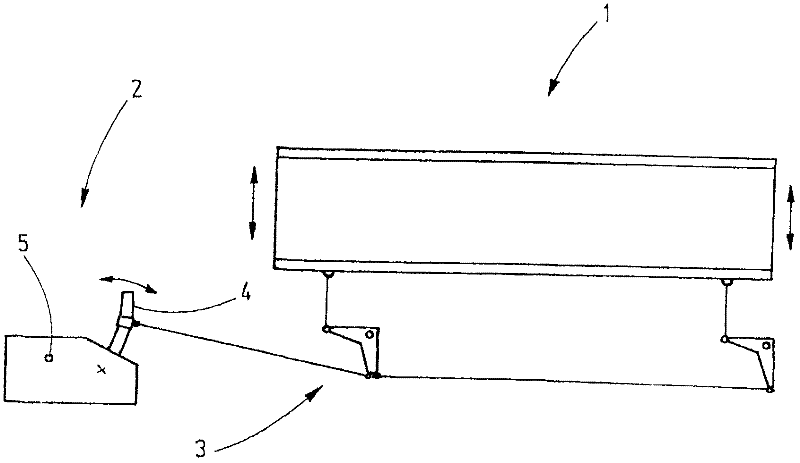

[0065] exist figure 1The corresponding shaft drive 2 of the heald frame 1 is shown in , which causes the vertical movement of the heald frame 1 via the connecting rod 3 as indicated by the two arrows. The shaft drive 2 has a rocker arm 4 that can perform a reciprocating swinging motion. This movement comes from the rotation of the shaft 5 via, for example, an eccentric gear mechanism. If this rotation is a constant accelerated or decelerated rotary motion, then the motion of the heald frame 1 should essentially correspond to a sinusoidal motion. In this case, the sinusoidal form of the deviation, which drives the rocker arm 4 via the connecting rod 3 and the connecting rod, can be ignored. In the shaft drive according to the invention, however, the movement of the shaft 5 is not a constant rotational movement. As an alternative, functioning as a reduction gear, according to figure 2 The gear mechanism 6 produces a rotational movement on an output shaft coincident with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com