Method for synthesizing micro-sphere used for electric paper by titanium dioxide or dye embedding method and application of micro-sphere used for electric paper in medium with low dielectric constant

A technology of electronic paper and embedding method, applied in instruments, optics, identification devices, etc., can solve the problems of heavy pigment ratio, environmental pollution, shortening the life of electrophoretic displays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] The method for synthesizing microspheres for electronic paper by dye embedding method includes the following steps:

[0130] 1) Selection of raw materials

[0131] ①Selection of core monomer: 10-20 parts of methyl methacrylate,

[0132] 10-20 parts of n-butyl methacrylate,

[0133] 3 to 5 parts of allyl methacrylate;

[0134] ②Dye selection: 0.1~1.0 parts of solvent yellow dye 19;

[0135] ③Selection of emulsifier: 0.1~0.8 parts of sodium lauryl sulfate;

[0136] ④Initiator selection: 0.1~0.8 parts of potassium peroxodisulfate;

[0137] ⑤Additives: 0.02~0.20 parts of sodium bicarbonate;

[0138] ⑥Deionized water: 60-100 parts;

[0139] 2) Dyeing of the core monomer: Dissolve 0.1 to 1.0 part of Solvent Yellow Dye 19 in 10 to 20 parts of methyl methacrylate, 10 to 20 parts of n-butyl methacrylate and 3 to 5 parts of allyl methacrylate In the monomer mixture of the ester, fully stir and dissolve it and filter to obtain the dyed monomer mixture, which is r...

Embodiment 2

[0159] The method for synthesizing microspheres for electronic paper by dye embedding method includes the following steps:

[0160] 1) Selection of raw materials

[0161] ①Selection of core monomers: 5-20 parts of methyl methacrylate, 5-20 parts of n-butyl acrylate,

[0162] 5-20 parts of divinylbenzene;

[0163] ② Dye selection: 0.1~1.0 parts of solvent red dye 109;

[0164] ③Selection of emulsifier: sodium lauryl sulfate 0.1~0.8 parts,

[0165] 0.1~0.8 parts of sodium dodecylbenzene sulfonate;

[0166] ④Initiator selection: 0.1~0.8 parts of potassium peroxodisulfate;

[0167] ⑤Additives: 0.02~0.20 parts of sodium bicarbonate;

[0168] ⑥Deionized water: 60-100 parts;

[0169] 2) Dyeing of the core monomer: Dissolve 0.1 to 1.0 part of solvent red dye 109 in 5 to 20 parts of methyl methacrylate, 5 to 20 parts of n-butyl acrylate and 5 to 20 parts of divinylbenzene monomer In the mixed solution, after fully stirring and dissolving, filter to obtain the dyed monom...

Embodiment 3

[0189] The method for synthesizing microspheres for electronic paper by dye embedding method includes the following steps:

[0190] 1) Selection of raw materials

[0191] ①Selection of core monomers: 5-20 parts of methyl methacrylate, 5-20 parts of n-butyl acrylate,

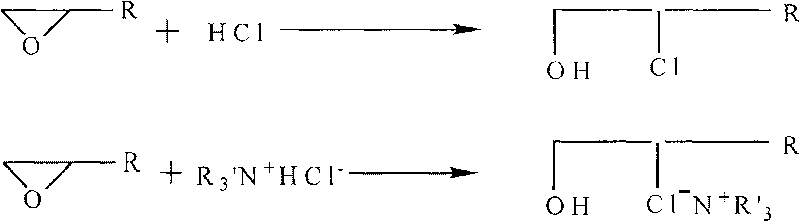

[0192] 5-20 parts of divinylbenzene, 5-20 parts of glycidyl methacrylate;

[0193] ② Dye selection: Solvent blue dye 35 0.1~1.0 parts;

[0194] ③Selection of emulsifier: 0.1~2.0 parts of sodium lauryl sulfate,

[0195] 0.1~2.0 parts of sodium dodecylbenzene sulfonate;

[0196] ④Initiator selection: 0.1~0.8 parts of potassium peroxodisulfate;

[0197] ⑤Additives: 0.12~0.60 parts of sodium bicarbonate;

[0198] ⑥Deionized water: 60-100 parts;

[0199] 2) Dyeing of the core monomer: Dissolve 0.1~1.0 part of solvent blue dye 35 in 5~20 parts of methyl methacrylate, 5~20 parts of n-butyl acrylate, 5~20 parts of divinylbenzene and 5~ In 20 parts of the monomer mixture of glycidyl methacrylate, fully sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com