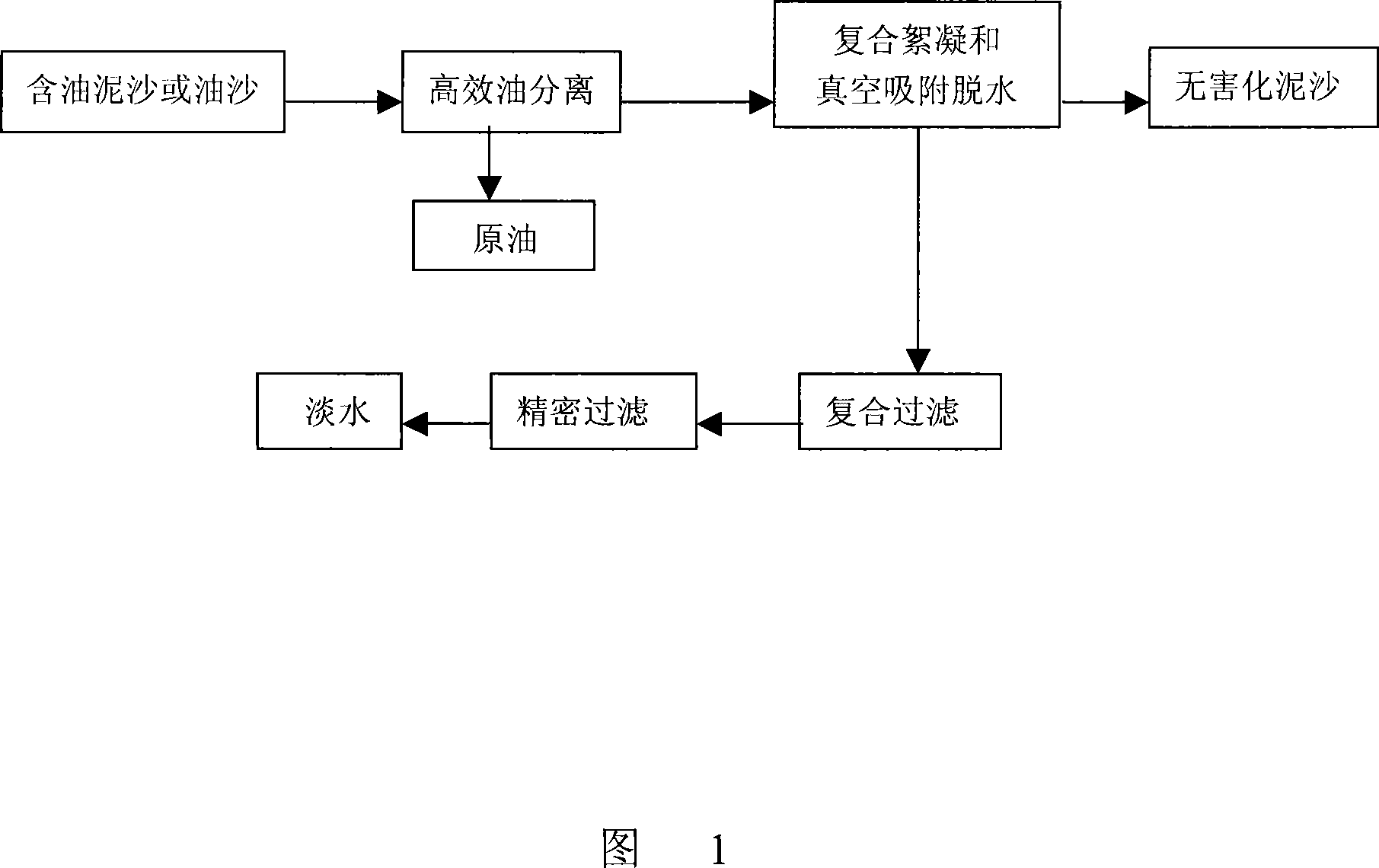

Oil mud harmless treatment and resource reclamation method

A harmless treatment and resource recovery technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of low separation efficiency of chemical separation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0134] 2.1 Purpose of the experiment: This test process completes the compound flocculation project of sediment, and verifies various design parameters during the test process.

[0135] 2.2 Scale: process 2 tons of oily sediment or oil sand per hour. The experiment reached the industrial level.

[0136] 2.3 Sampling: Take oily sediment or oil sand samples at the joint station.

[0137] 2.4 Equipment used: 2 composite flocculation tanks of 0.5 tons, and the vacuum dehydration equipment can process 2 tons of sediment per hour. The vacuum dehydration equipment is equipped with a washing device, and its supporting equipment is an air compressor and a vacuum pump. , a composite filter.

[0138] 2.5 Experimental process

[0139] 2.5.1 Preparation of various additives:

[0140] Prepare 200Kg of sodium polyacrylate solution at a ratio of 0.1%, and add 10% to oily sediment or oil sand; prepare 200Kg of deacylated chitin at a ratio of 5%, and add 10% to oily sediment or oil sand %;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com