Sprinkling device for deicing fluid in coal transporting train carriage

A technology of spraying device and antifreeze, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of coal sticking to the bottom, coal hanging on the wall, difficult unloading, coal freezing blocks, etc., to reduce labor intensity and facilitate assembly and disassembly. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

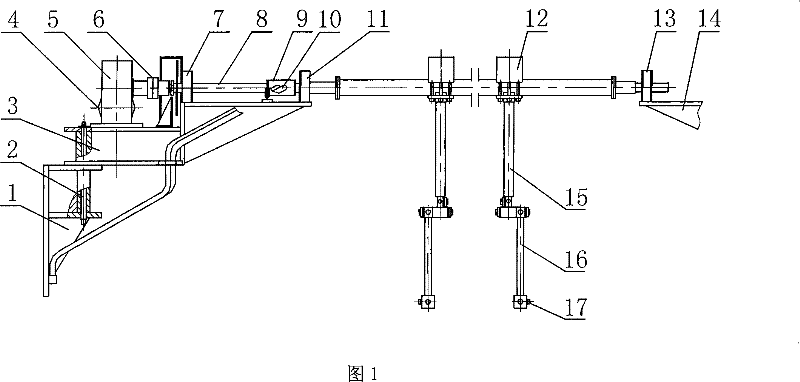

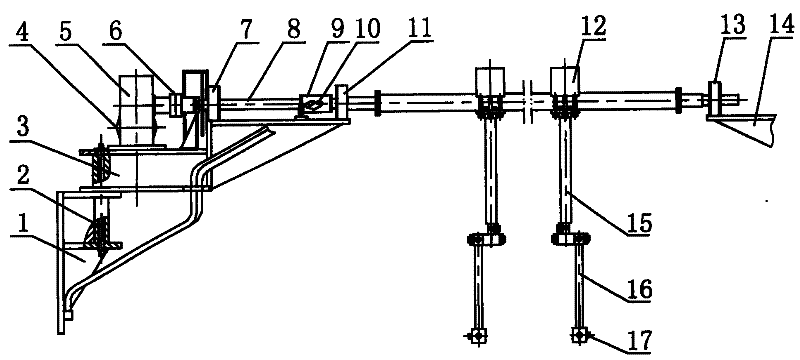

[0024] Such as figure 1 , the spraying device of antifreeze in the coal train carriage comprises a left column bracket (1), a pin shaft (2), a left bracket (3), a motor (4), a reducer (5), a shaft coupling (6), a left Bearing seat assembly (7), hollow main shaft (8), water sealing device (9), pressure-resistant hose (10), middle bearing seat assembly (11), spray arm pipe (12), right bearing seat assembly (13), right support (14) and nozzle (17). Left column support (1) and right support (14) are fixedly clamped on the column on rail both sides by pressing plate and stud, nut, and two supports respectively have a horizontal plane. Left column support (1) and left support (3) are hinged by bearing pin (2), and it is fastened as a whole by bolt and left column support (1) when left support (3) does not rotate. The reducer (5) is fixed by bolts on the left horizontal plane of the left bracket (3), and the left bearing seat assembly (7), water sealer (9) and middle bearing seat a...

Embodiment approach 2

[0032] The difference from Embodiment 1 is that the distance from the axis of the hollow main shaft (8) to the rail surface of the train is 5000 mm. The distance from the hinge axis between the upper arm tube (15) and the lower arm tube (16) to the axis of the hollow main shaft (8) is 1600mm, and the distance from the hinge axis to the lower end of the lower arm tube is 1300mm. The maximum diameter of the outer circle of the hollow spindle is 89mm. The distance between the axes of the upper arm pipes (15) of the two spraying arm pipes (12) is 1700 mm, and is symmetrical about the center line of the train track.

[0033]The suitable situation for this method is: the locomotive of the coal transport train passes under the hollow main shaft (8), the top of the locomotive to the rail surface does not exceed 4800mm, the inner width of the carriage is 2750-2900mm, the inner height is 1900-2200mm, and the distance from the top of the carriage to the rail surface It is 3080~3290mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com