Method for leveling bent plastic flat plate

A plastic and flat panel technology, applied in the field of acrylic light guide plate processing, can solve the problems of expensive equipment, easy bending and deformation of products, and decreased uniformity of display backlight, etc., and achieve the effect of convenience and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

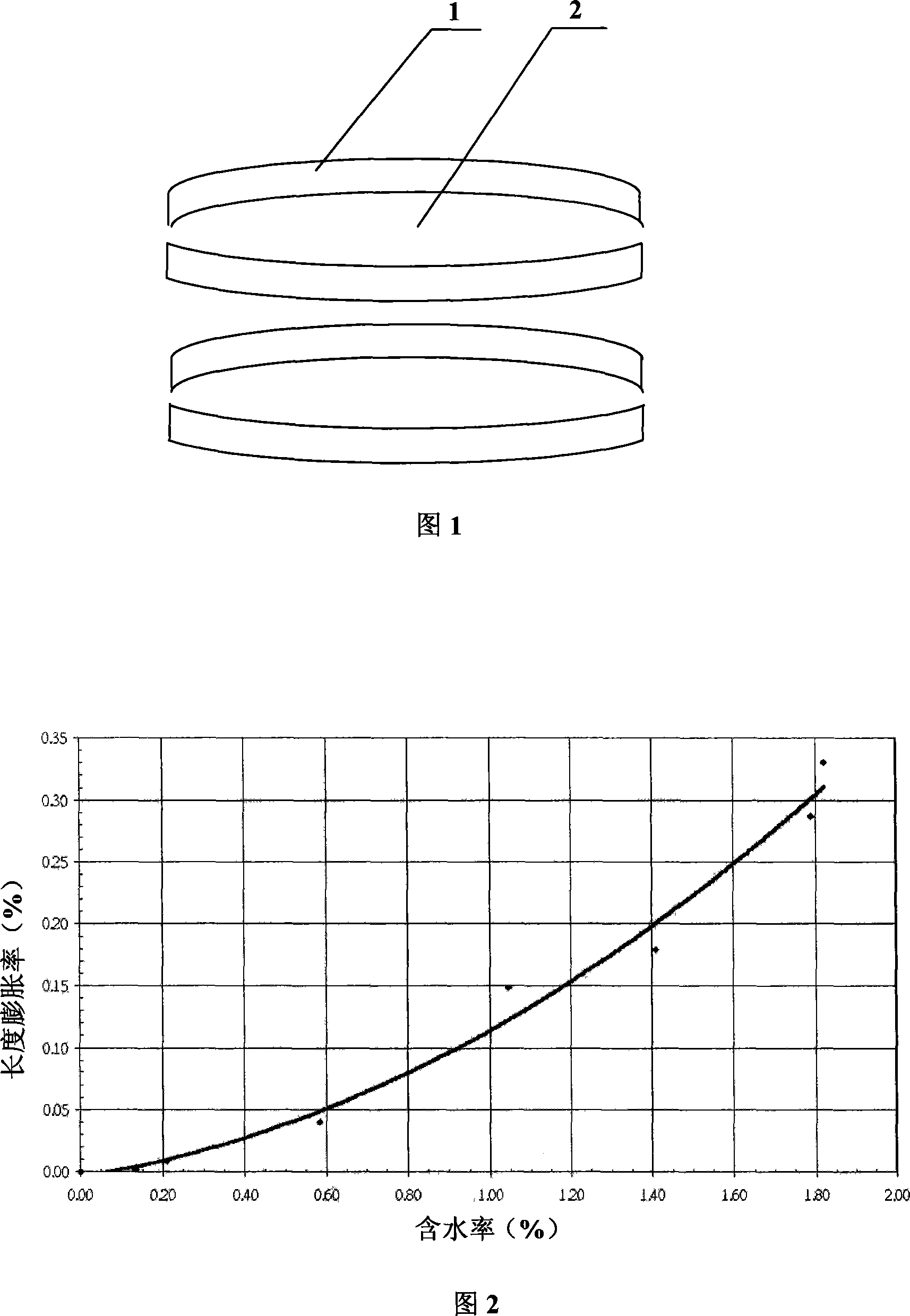

[0024] Embodiment one: referring to shown in accompanying drawing 1, a kind of back flattening method of curved plastic sheet material, the plastic sheet material thickness of processing is 4 millimeters, comprises the following steps:

[0025] (1) Referring to the stacking method of the curved plastic sheets 1 in accompanying drawing 1, stack the curved plastic sheets from bottom to top, so that the concave surface of the odd-numbered plastic sheets from bottom to top is upward, and the concave surface of the even-numbered plastic sheets Below, two curved plastic sheets are stacked in a symmetrical manner, with the concave faces facing each other, forming a concave void 2;

[0026] (2) Add water in the middle of the concave space formed by the concave surfaces of two symmetrical curved plastic sheets, press for 8 to 12 hours, and detect its flatness;

[0027] (3) Take out the plastic sheets that meet the standards, and continue to press the plastic sheets that do not meet the...

Embodiment 2

[0029] Embodiment two: a kind of back-flat method of curved plastic sheet material, the thickness of the curved plastic sheet material to be processed is 8 millimeters, comprises the following steps:

[0030] (1) Stack the curved plastic sheets from bottom to top, so that the concave surface of the odd-numbered plastic sheets from bottom to top is upward, and the concave surface of the even-numbered plastic sheets is downward, and two curved plastic sheets are stacked in a symmetrical manner, The concave surfaces face each other to form concave voids;

[0031] (2) Add water in the middle of the concave space formed by the concave surfaces of two symmetrical curved plastic sheets, set the temperature at about 35°C, and the humidity at about 70%, press for 20 to 24 hours, and check its flatness;

[0032] (3) Take out the plastic sheets that meet the standards, and continue to press the plastic sheets that do not meet the standards according to the above steps (1) and (2).

[00...

Embodiment 3

[0034] Embodiment three: a kind of back-leveling method of curved plastic sheet material, the thickness of the curved plastic sheet material to be processed is 10 millimeters, comprises the following steps:

[0035] (1) Stack the curved plastic sheets from bottom to top, so that the concave surface of the odd-numbered plastic sheets from bottom to top is upward, and the concave surface of the even-numbered plastic sheets is downward, and two curved plastic sheets are stacked in a symmetrical manner, The concave surfaces face each other to form concave voids;

[0036] (2) Add water in the middle of the concave space formed by the concave surfaces of two symmetrical curved plastic sheets, set the temperature at about 30°C, and the humidity at about 65%, press for 24 to 28 hours, and check its flatness;

[0037] (3) Take out the plastic sheets that meet the standards, and continue to press the plastic sheets that do not meet the standards according to the above steps (1) and (2)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com