Intelligentize device used for fine material pipeline pneumatic conveying monitoring

A pneumatic conveying and pipeline technology, applied in the field of online monitoring devices, can solve the problems of complex algorithm, large amount of calculation, poor reliability, etc., and achieve the effect of less operation and maintenance, low cost, and overcoming measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

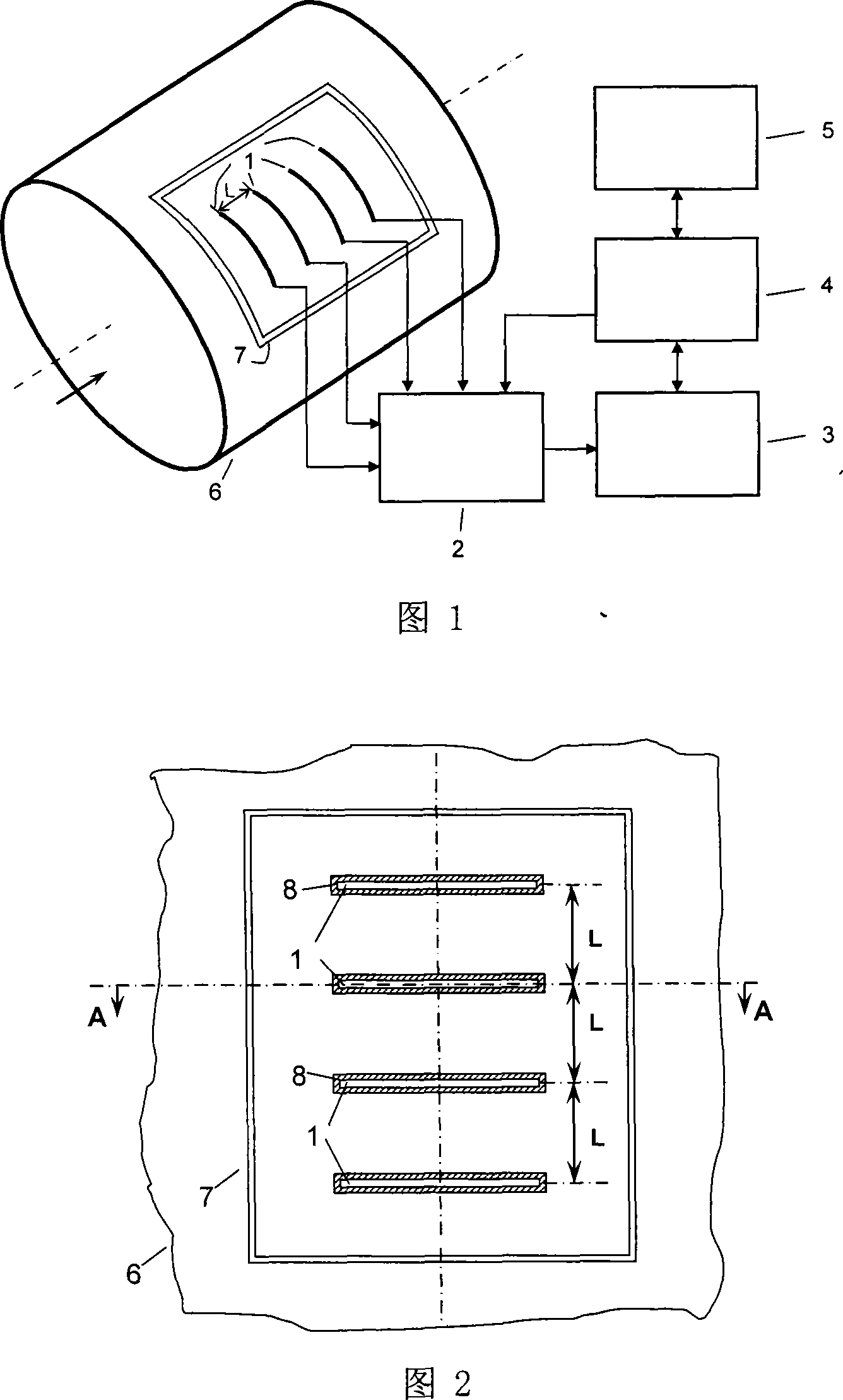

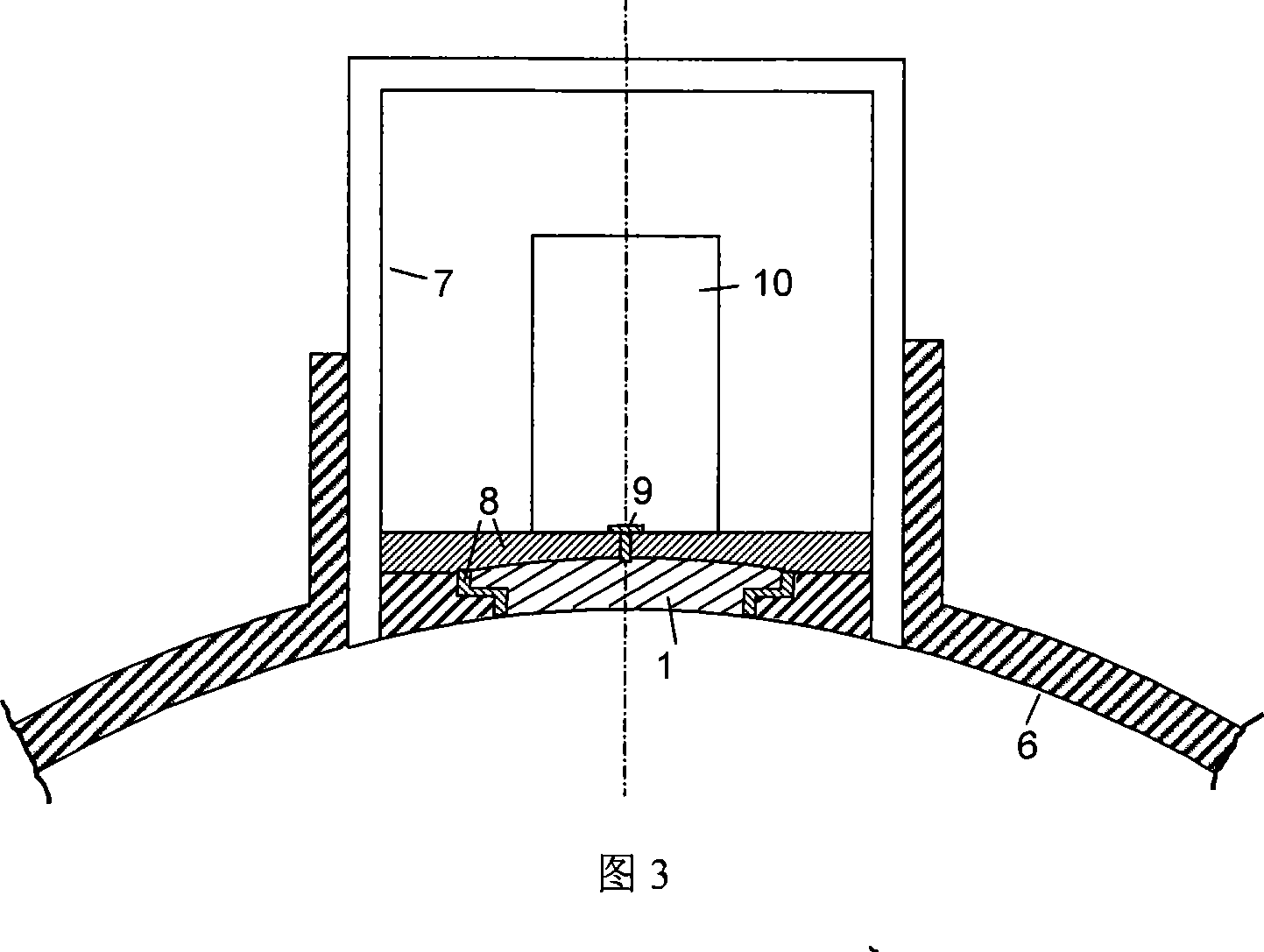

[0015] The intelligent device for powder pipeline pneumatic conveying monitoring of the present invention will be described in conjunction with the accompanying drawings and examples. The arrows near the axis of the pipeline in Figure 1 represent the flow direction of the powder in the delivery pipeline.

[0016] As shown in Figure 1, the intelligent device for powder pipeline pneumatic conveying monitoring of the present invention is installed on the powder material conveying pipeline 6, and the device includes an organic casing 7, which includes static electricity connected by electricity in the casing 7. The sensor electrode array 1 and the electronic circuit board 10 , the electronic circuit board 10 includes a signal processing acquisition unit 2 , a data processing unit 3 , a system control unit 4 and a user interface unit 5 connected electrically. The device picks up the electrostatic signal induced by the powder in the conveying pipeline through the electrostatic senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com