Fuel pump and filter assembly

A filter assembly, fuel pump technology, used in engine components, machines/engines, liquid fuel feeders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

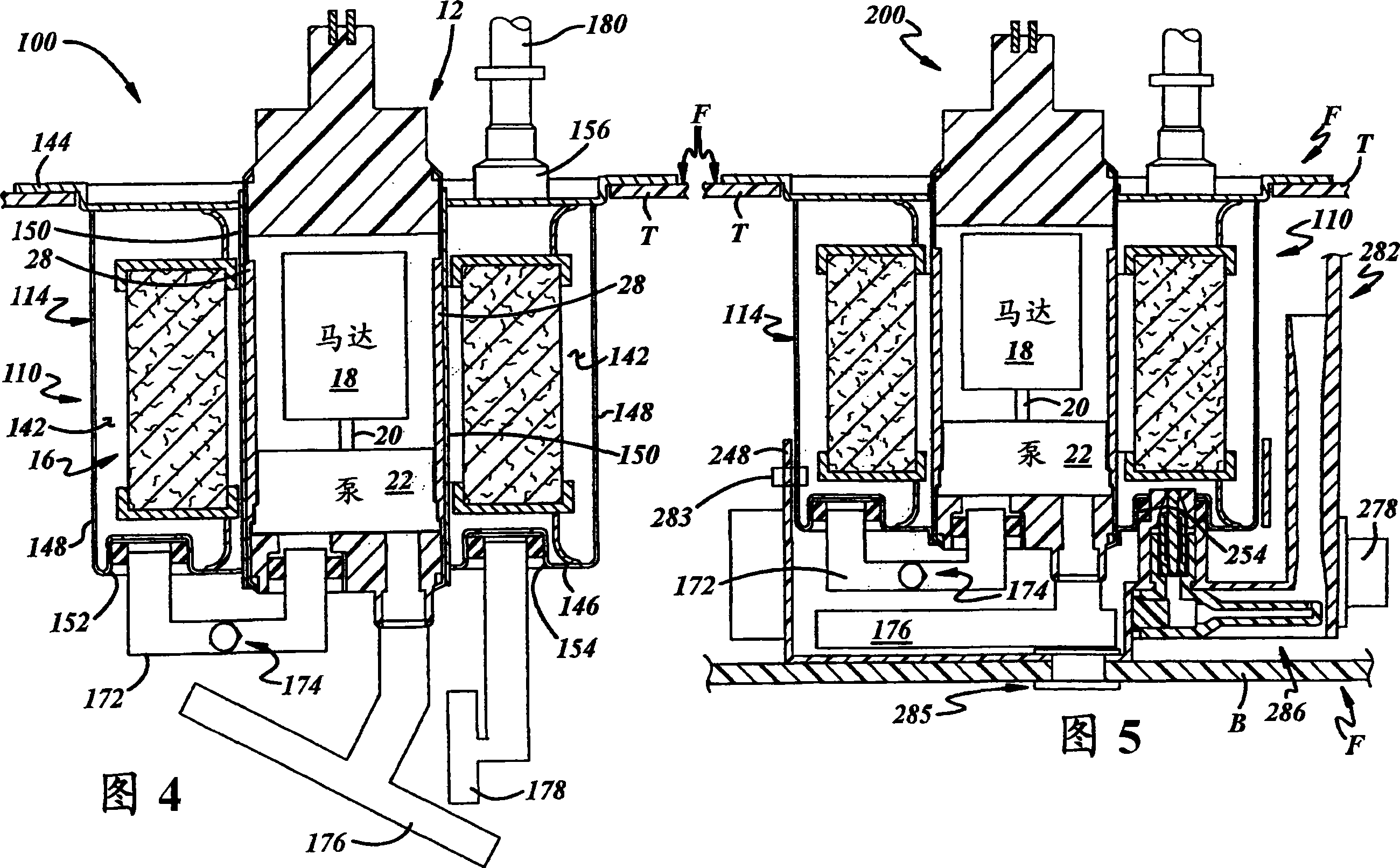

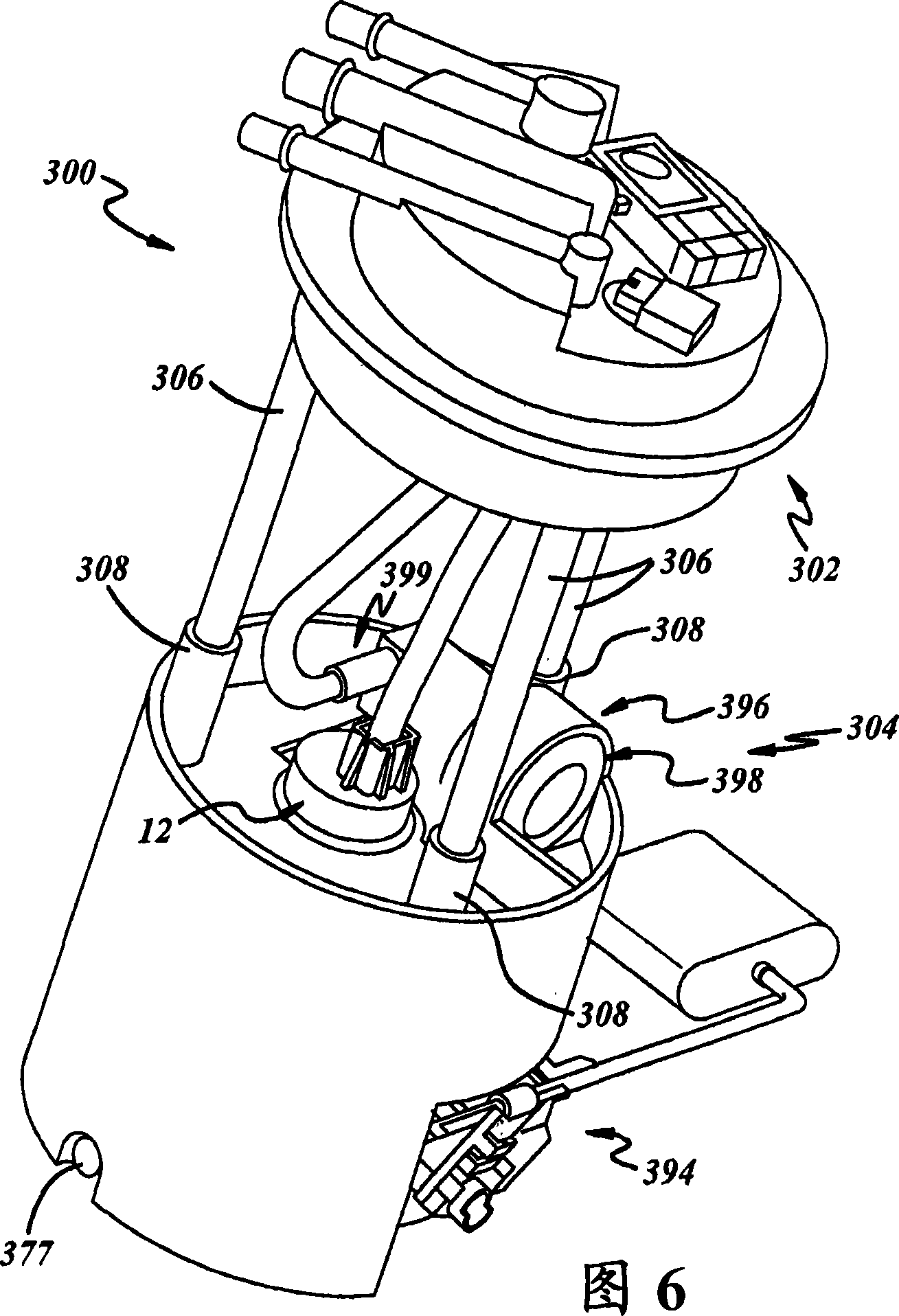

[0019] Referring to the drawings in more detail, FIGS. 1-3 illustrate a presently preferred form of a fuel pump and filter assembly 10 for drawing fuel from a fuel tank (not shown) and pressurizing and Fuel is filtered for delivery to the engine (not shown). As best shown in Figure 3, assembly 10 includes a fuel pump assembly 12 for pumping and pressurizing fuel, a housing 14 for carrying fuel pump assembly 12, and a housing 14 for filtering fuel from the fuel pump assembly 14 carried in housing 14. Filter 16 for pressurized fuel received at pump assembly 12 . Assembly 10 may be used alone or in conjunction with a fuel pump module (not shown) for insertion into a fuel tank.

[0020] Fuel pump assembly 12 may be any suitable pump device, such as an electromechanical pump device, that pressurizes fuel for delivery to the upstream or inlet side of filter 16 . Fuel pump assembly 12 is centrally positioned relative to filter 16 and housing 14 such that filter 16 and housing 14 su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com