Printing press with several operating zones

A control device, safety technology, applied in the general parts of printing machinery, printing machines, printing and other directions, can solve the problem of insufficient, the operator can not see the machine and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

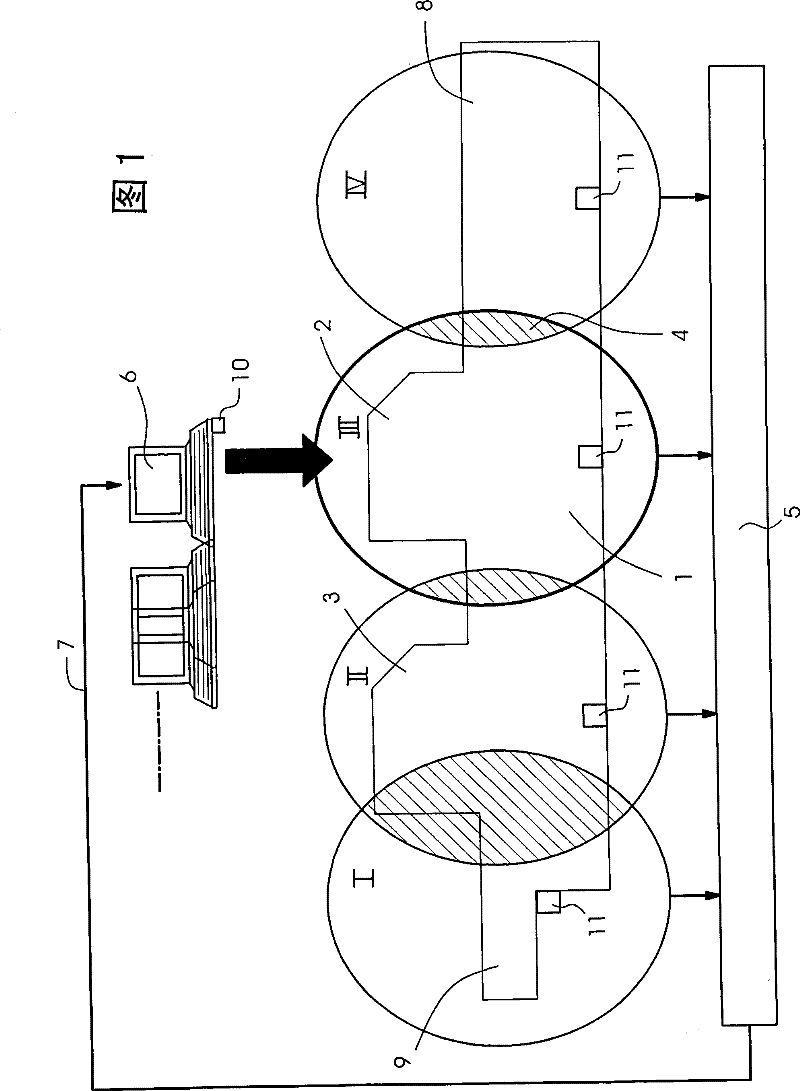

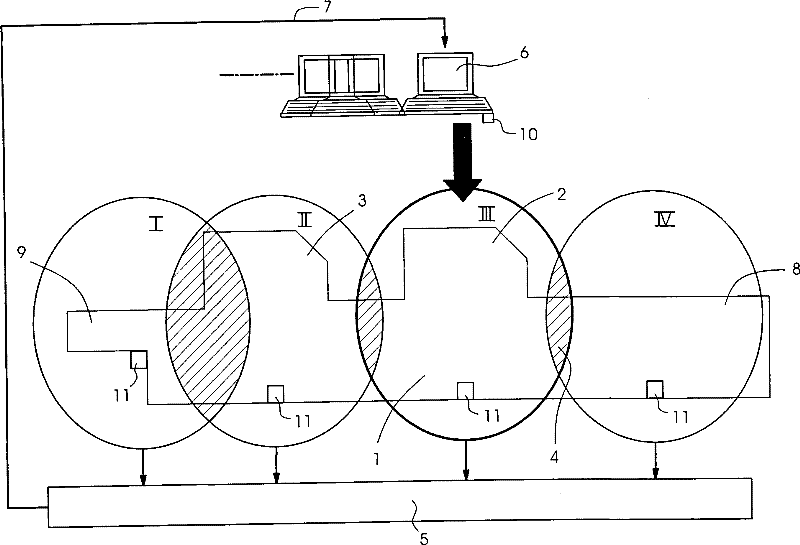

[0021] The printing press 1 shown in the drawing has two printing units 2 , 3 as well as a feeder 8 and a delivery 9 , which are each assigned to an operating area I, II, III, IV. The printing units 2 , 3 as well as the feeder 8 and delivery 9 are controlled by a machine controller 5 . Furthermore, the machine controller 5 has a wireless interface, which can be designed as a wireless connection in the form of a W-LAN connection or a Bluetooth connection. Via this wireless interface, the machine controller 5 can communicate with a movable control device, for example a correspondingly designed laptop computer 6 . Communication between the laptop 6 and the machine controller 5 then takes place wirelessly via the air interface 7 . A plurality of notebook computers 6 can also be connected wirelessly to the machine controller 5 . The operator can thus control the printing press 1 via the laptop 6 and make adjustments on the printing units 2 , 3 , on the feeder 8 and on the deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com