Preparing technique of back-up ring

A manufacturing process and retaining ring technology, applied in the field of standard parts manufacturing process, to achieve the effect of reducing cost, high utilization rate and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

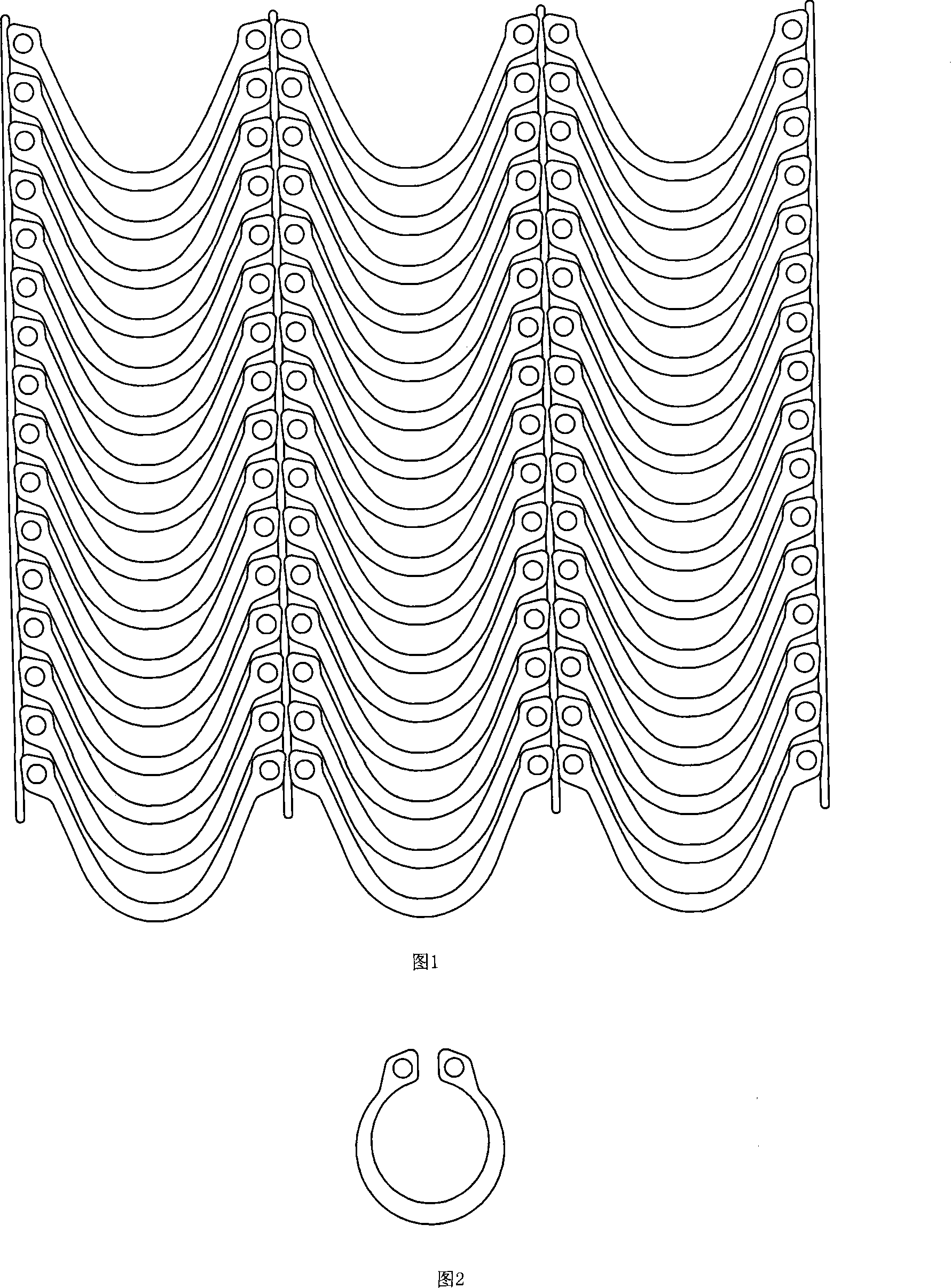

[0014] The production process of this kind of retaining ring, it first installs the mold on the punch equipment, takes the strip and puts it on the punch equipment, the strip can be iron plate or steel plate, and then uses the mold of the punch equipment to punch the strip Cut into an arc-shaped strip with a certain curvature; according to the different specifications and models of the retaining ring, the mold can be replaced, and the specifications and models are different, and the curvature of the arc-shaped strip after punching is also different; The arc-shaped strip is crimped into a circle with an opening by using a punching machine to become a retaining ring. In the above-mentioned process, the arc-shaped strips punched by the die can be wavy slats, and then the wave crests of the wavy arc-shaped strips are cut and divided to become arc-shaped strips with only one arc. Then curl the arc-shaped strips with only arcs to form retaining rings; of course, you can also directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com