Centrifugal fan and production method thereof

A centrifugal fan and manufacturing method technology, applied in the direction of mechanical equipment, non-variable pumps, machines/engines, etc., can solve the problems of increased operating procedures, interference between products and molds, increased welding points, etc., to achieve production cost suppression, Realization of productivity and reduction of operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

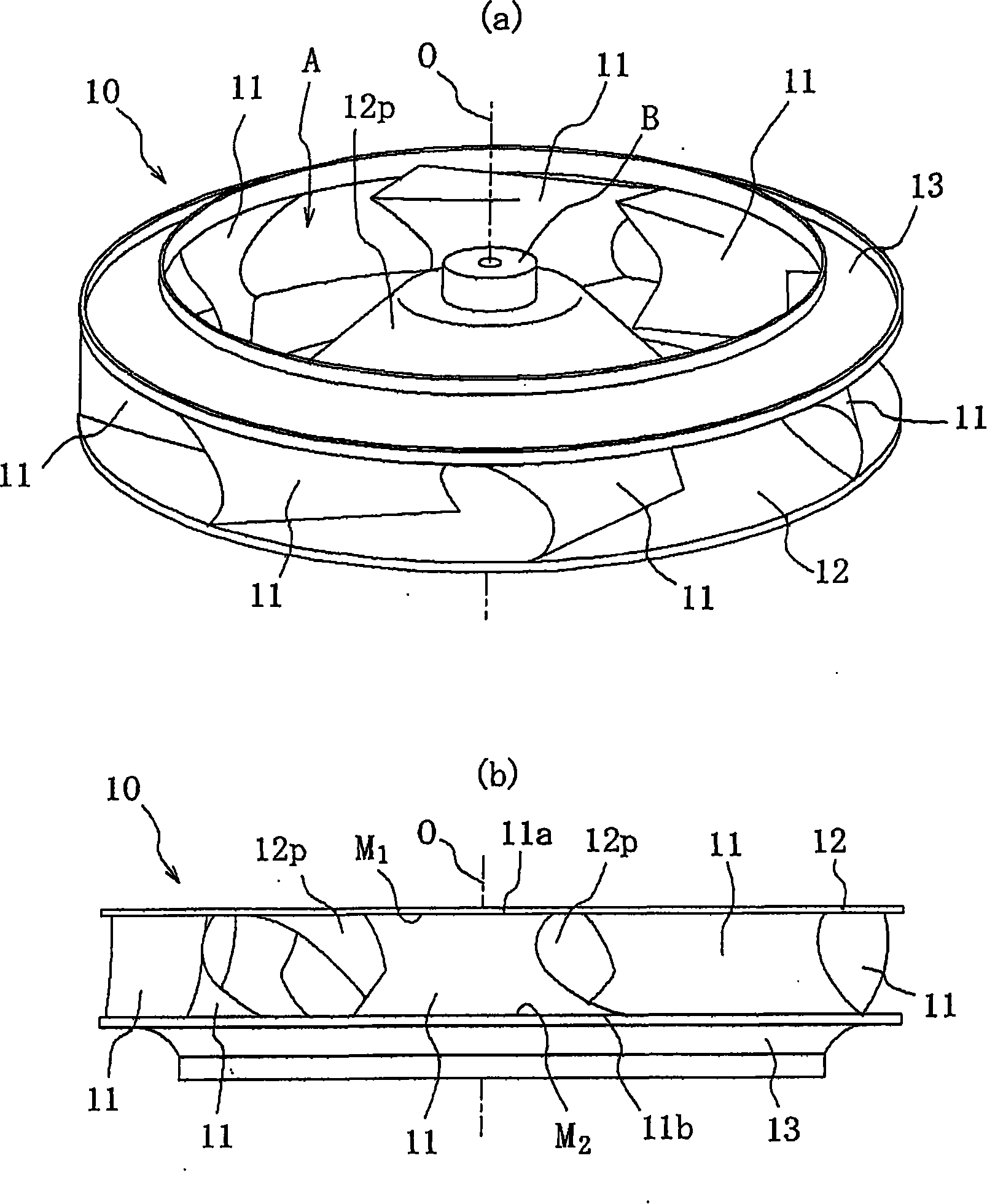

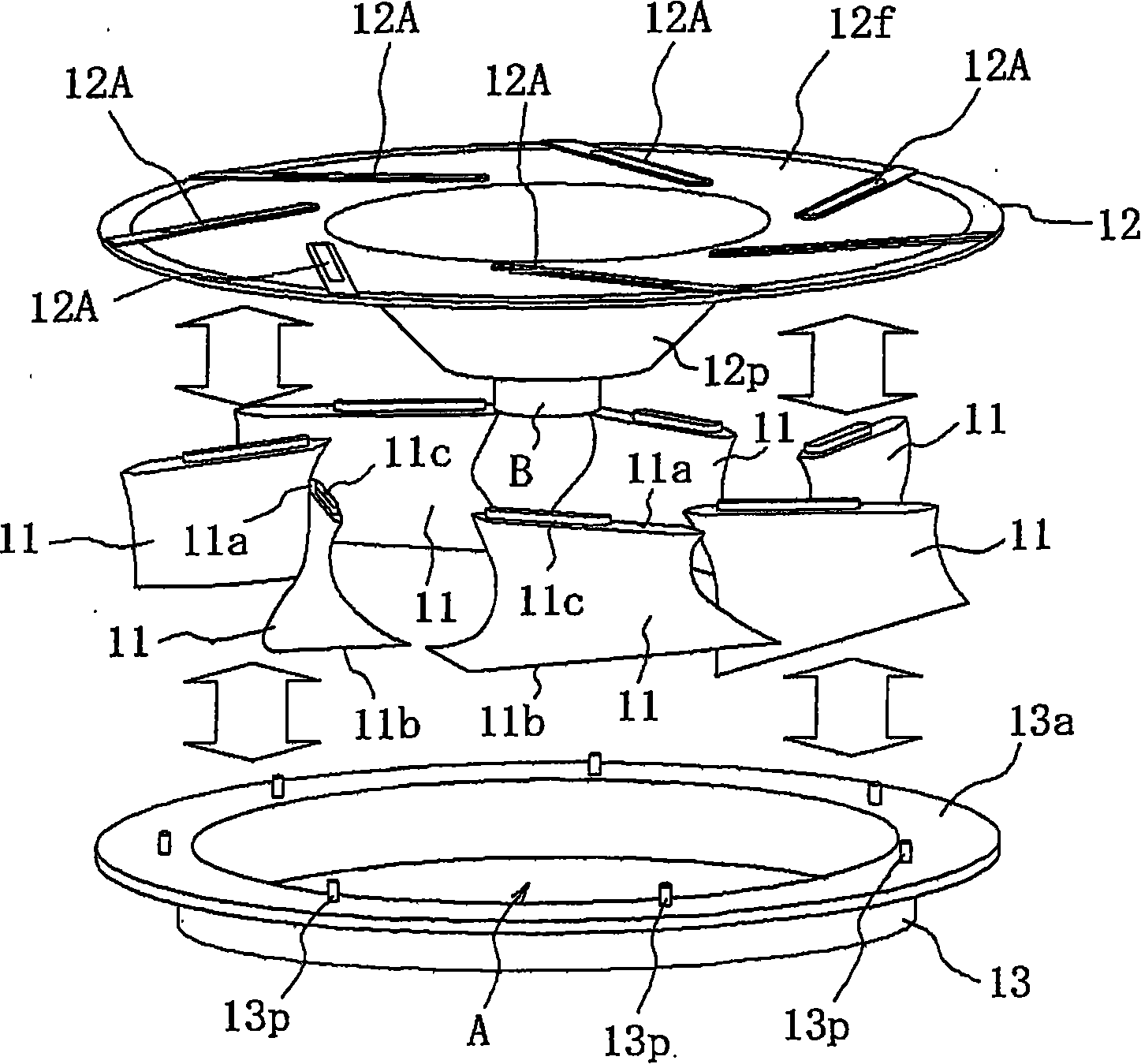

[0072] Hereinafter, the centrifugal fan of the present invention and its manufacturing method will be described in detail with reference to the drawings.

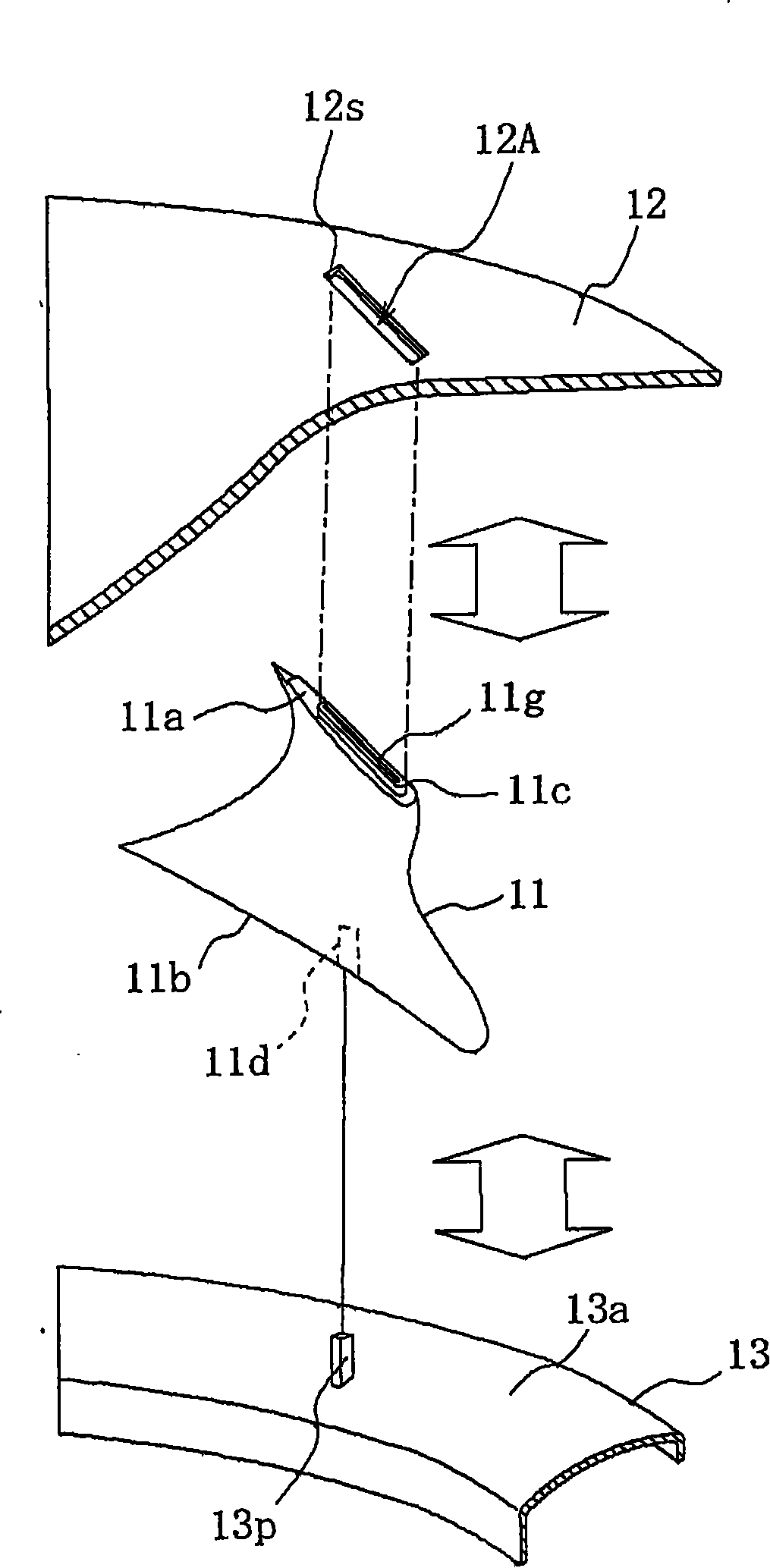

[0073] figure 1 (a) and (b) are a perspective view of the turbo blower 10 as one aspect of the present invention, and a side view of a state in which the aspect is reversed, respectively, figure 2 is true figure 1 (b) is a perspective view of the disassembled state of the turbo blower 10 .

[0074] The turbo blower 10 is made of thermoplastic resin, such as figure 1 As shown, seven blade members 11 are arranged at intervals around the axis O, and a main plate 12 and a shroud 13 are connected so as to sandwich the blade members 11 .

[0075] The blade members 11 are respectively formed of thermoplastic resin such as figure 2 A part of it has two end parts 11a and 11b as illustrated, and is formed into a three-dimensional blade surface shape for the purpose of improving the performance of the turbo blower.

[0076] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com