Integral heat pump of heat pump laundry dryer

A technology of a washing-drying machine and a heat pump device, applied in the field of washing machines, can solve problems such as troublesome maintenance, and achieve the effect of easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

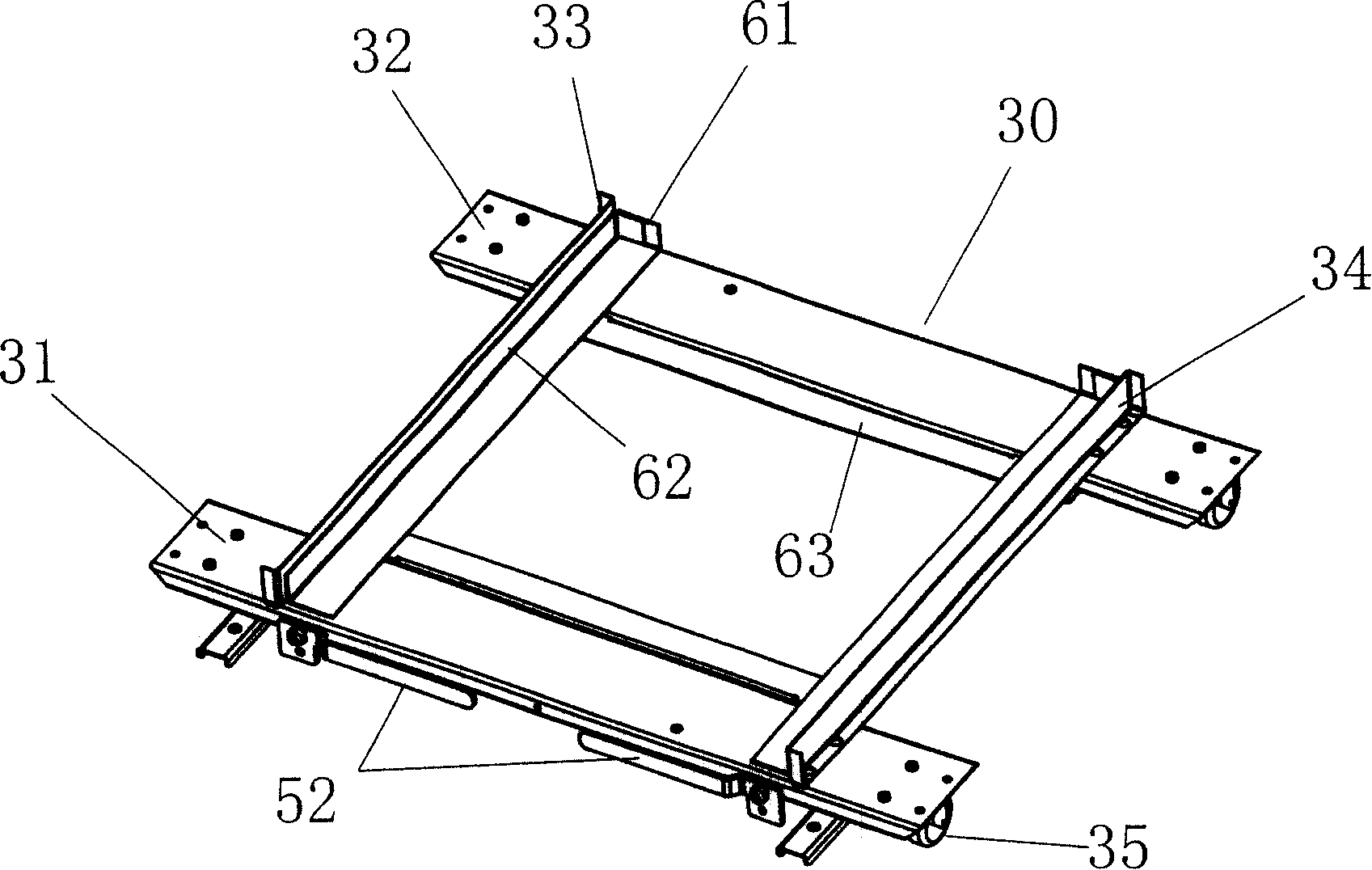

[0034] image 3 , Figure 4Shown is a specific embodiment of a conveying device with a lifting mechanism. The lifting device described in this embodiment is a lifting device realized by using a cam. Specifically, the left and right ends of the front and rear cross bars of the bottom frame 30 pass Provide a rotating shaft 51 with two identical cams 50, the cams on the left and right rotating shafts 51 are arranged oppositely, and the end of the rotating shaft is provided with a handle 52. On the four cams 50 of the above-mentioned two rotating shafts, a fixing hole 53 is provided on the handle.

[0035] The positioning device is a rectangular frame with rectangular box positioning baffles 61, 62 for the cooling and heat pump box. Both sides of the rectangular frame are provided with slideways for pushing and pulling out the cooling and heat pump box. The rectangular frame A slide block or a slide plate 63 (the specific embodiment shown in the figure is a slide plate) is provi...

Embodiment 2

[0039] Embodiment 2 is a four-cam lifting device that can realize the steady lifting of the entire refrigeration heat pump box by pulling the handle 52 at the end of a rotating shaft with one hand. Rod mechanism to realize four-cam synchronous rotation lifting. Specifically, the lifting mechanism is to pass a rotating shaft provided with two identical cams 50' on the left and right ends of the front and rear cross bars 31, 32 of the bottom frame 30, and the cams 50' on the left and right rotating shafts are arranged in the same direction, wherein A handle 52' is provided at one end of the rotating shaft, and a crank 53 is provided at the end of the other rotating shaft, and a connecting rod 54 is connected between the crank 53 and the handle 52' to form a parallelogram; the refrigeration heat pump box 1 The rectangular box body is arranged on the four cams of the two rotating shafts through a positioning device 60, and a fixing hole 63 is provided on the handle.

[0040] When...

Embodiment 3

[0043] The lifting mechanism can also use a jack, specifically, jacks are provided at the four corners of the bottom frame, and the rectangular box body of the refrigeration heat pump box is set on the jack through a positioning device, and the positioning device Long holes are provided, and fastening screws for locking the positioning device through the long holes of the positioning device are arranged on the bottom frame.

[0044] Described jack is hydraulic jack or screw jack. When the screw jack is used, the synchronous rotation of the two rotating shafts can be realized through a bevel gear transmission mechanism or a sprocket transmission mechanism.

[0045] The positioning device in each of the above embodiments may also be a slider or a slide plate provided at the bottom of the rectangular box body of the heat pump box and matched with the inner side of the rectangular bottom frame. When the rectangular box is raised, the horizontal movement does not occur through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com