Self-thermal insulation solid brick, building block or perforated brick for wall and producing method thereof

A self-insulating, solid brick technology, applied in the field of building materials, can solve the problems of insufficient wind pressure resistance, unsafe use, cumbersome construction, etc., and achieve the effect of low cost and overall cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

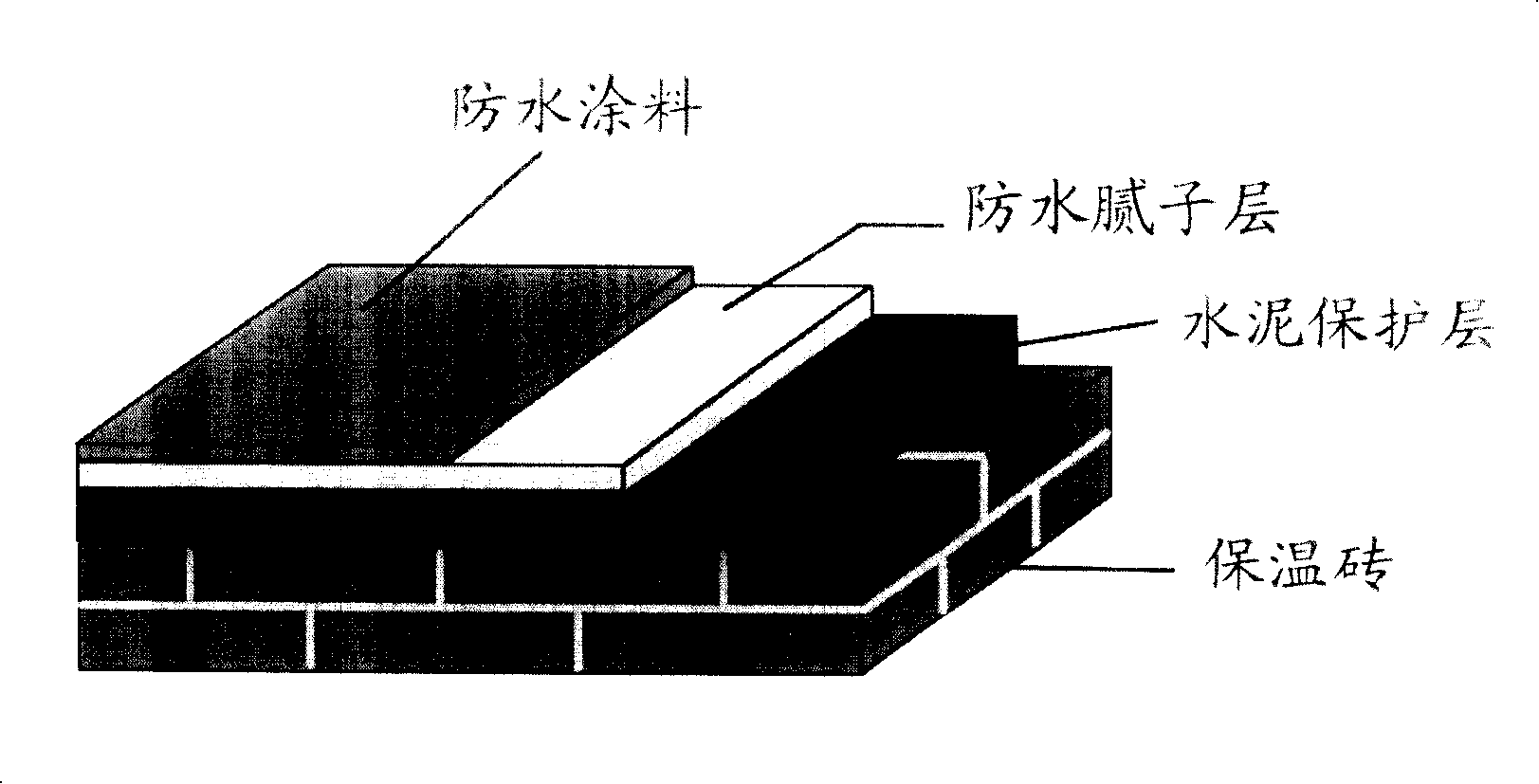

Image

Examples

Embodiment 1

[0027] Take each raw material (unit: kg) by the following parts by weight: cement 50, expanded perlite 5, fly ash 5;

[0028] First, mix cement and fly ash evenly, then use it to wrap expanded or closed-cell perlite, and finally add 18kg of water, use traditional brick-making technology to compress, do not calcine, and dry the slurry to get it.

[0029] The thermal insulation block prepared in this example is tested, and the performance results are shown in Table 1 (Note: The test method for bulk density: "Determination of the Apparent (Volume) Density of Foamed Plastics and Rubber" (GB / T6343-1995) ;: Thermal conductivity: "Determination of steady-state thermal resistance and related characteristics of thermal insulation materials" (GB10294-88); strength: "Technical Regulations for Soft Aggregate Concrete" JGJ51-2002).

[0030] Table 1 performance test result of thermal insulation block of the present invention

[0031] Test item name and unit

Embodiment 2

[0033] Each raw material was weighed in the following parts by weight (unit: kg): 30 cement, 45 closed-cell perlite, and 45 slag.

[0034] First, mix cement and slag evenly, then wrap closed-cell perlite with it, and finally add 48kg of water, use traditional brick-making technology to compress, do not calcine, and dry the slurry to get it.

[0035] The thermal insulation blocks prepared in this example were tested, and the performance results are shown in Table 2.

[0036] Table 2 performance test results of thermal insulation block of the present invention

[0037] Test item name and unit

Embodiment 3

[0039] Take each raw material (unit: kg) by the following parts by weight: cement 20, expanded perlite 5, fly ash 8;

[0040] First, mix cement and fly ash evenly, then wrap expanded perlite with it, and finally add 30-40% water of the total weight of the mixture. After pressing using traditional brick-making technology, no calcination is performed. After the slurry is dried, it is have to.

[0041] The thermal insulation blocks prepared in this example were tested, and the performance results are shown in Table 3.

[0042] Table 3 performance test results of thermal insulation block of the present invention

[0043] Test item name and unit

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com