Method for making magnetic nano particle based on solution co-deposition

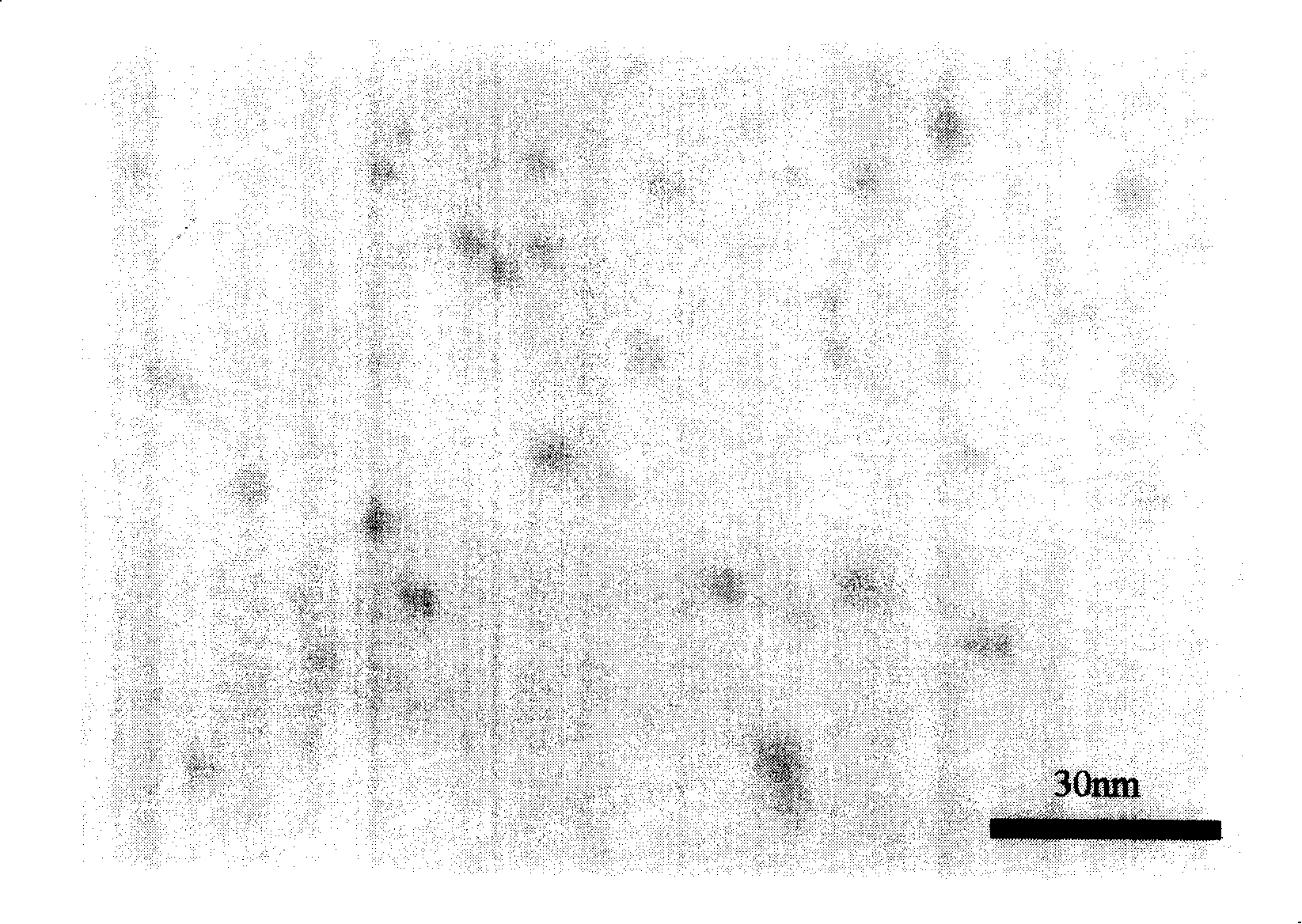

A technology of magnetic nanoparticles and co-precipitation method, which is applied in the direction of magnetism of inorganic materials, can solve problems such as difficult control of process conditions, particle size and dispersibility defects, and achieve the effect of avoiding agglomeration and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

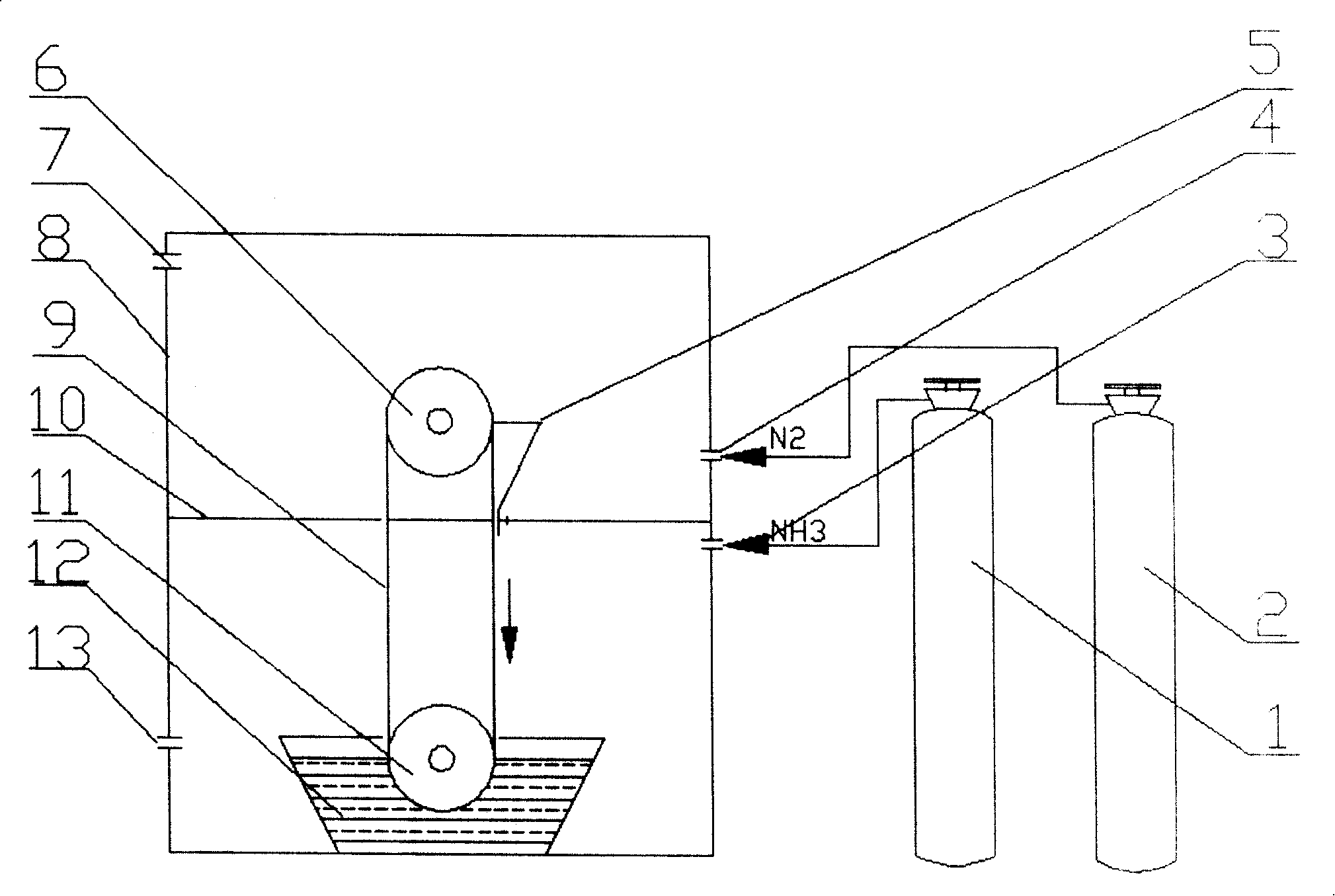

[0026] use as figure 1 device shown. Including ammonia gas cylinder 1, nitrogen gas cylinder 2, ammonia gas inlet 3, nitrogen gas inlet 4, sample solution tank 5, upper pulley 6, nitrogen gas discharge port 7, airtight container 8, stainless steel strip 9, isolation plate 10, lower pulley 11, Sample collection tank 12, ammonia discharge port 13;

[0027] In an airtight container 8, it is divided into upper and lower two containers by a separating plate 10, a sample collection tank 12 is arranged in the lower container, a lower pulley 11 is installed in the sample collection tank, and an upper pulley 6 is installed in the upper container above the lower pulley , the upper pulley 6 and the lower pulley 11 are connected with a thin stainless steel belt 9, and the stainless steel belt is driven to rotate by the pulley; a sample solution tank 5 is fixed on the upper pulley 6;

[0028] Ammonia gas discharge port 13 is arranged on the bottom side wall of airtight container 8, and n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com