Triaxial independent loading pressure chamber structure true triaxial apparatus

A true triaxial instrument, independent loading technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as sample deformation constraints, and achieve the effect of improving the technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

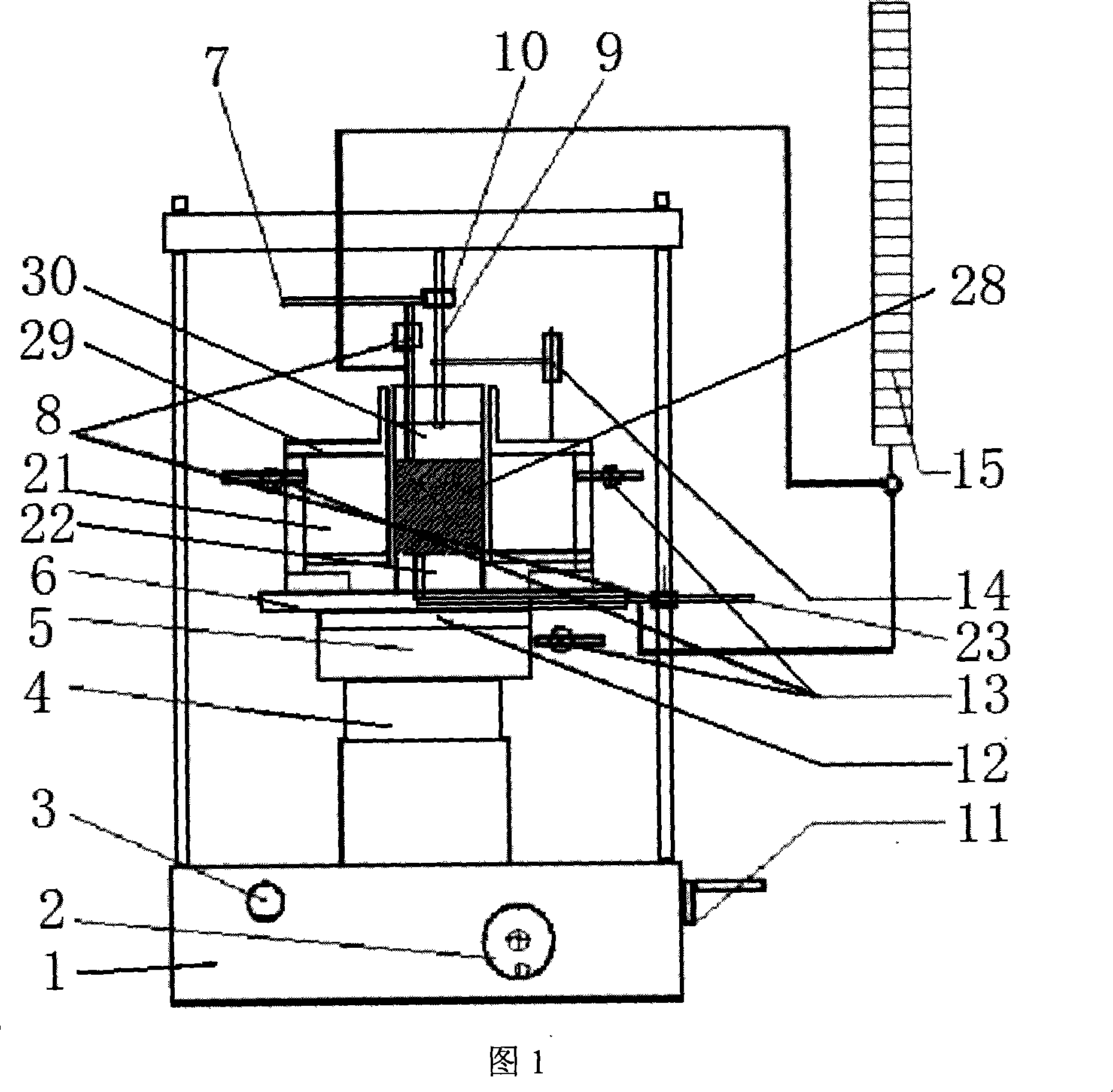

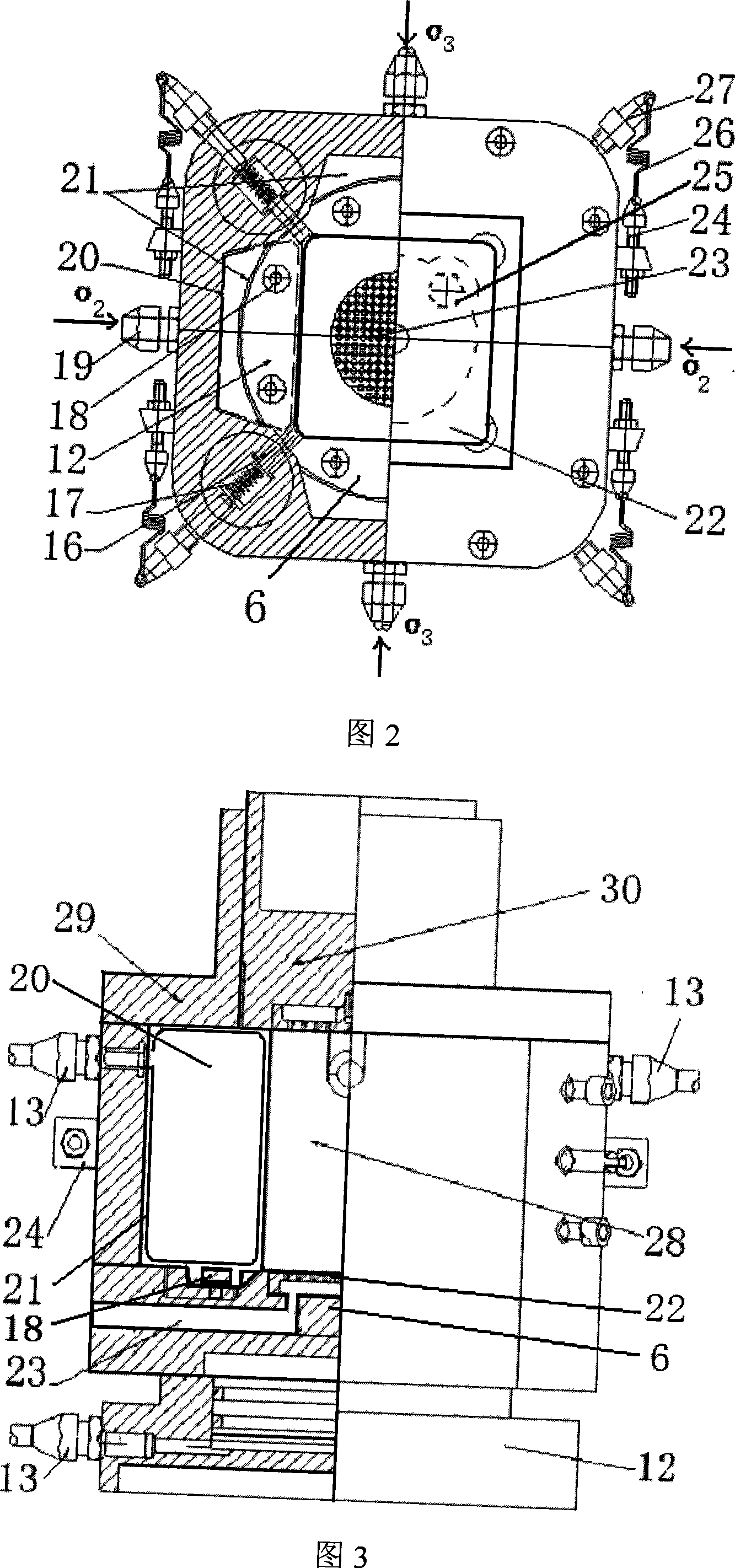

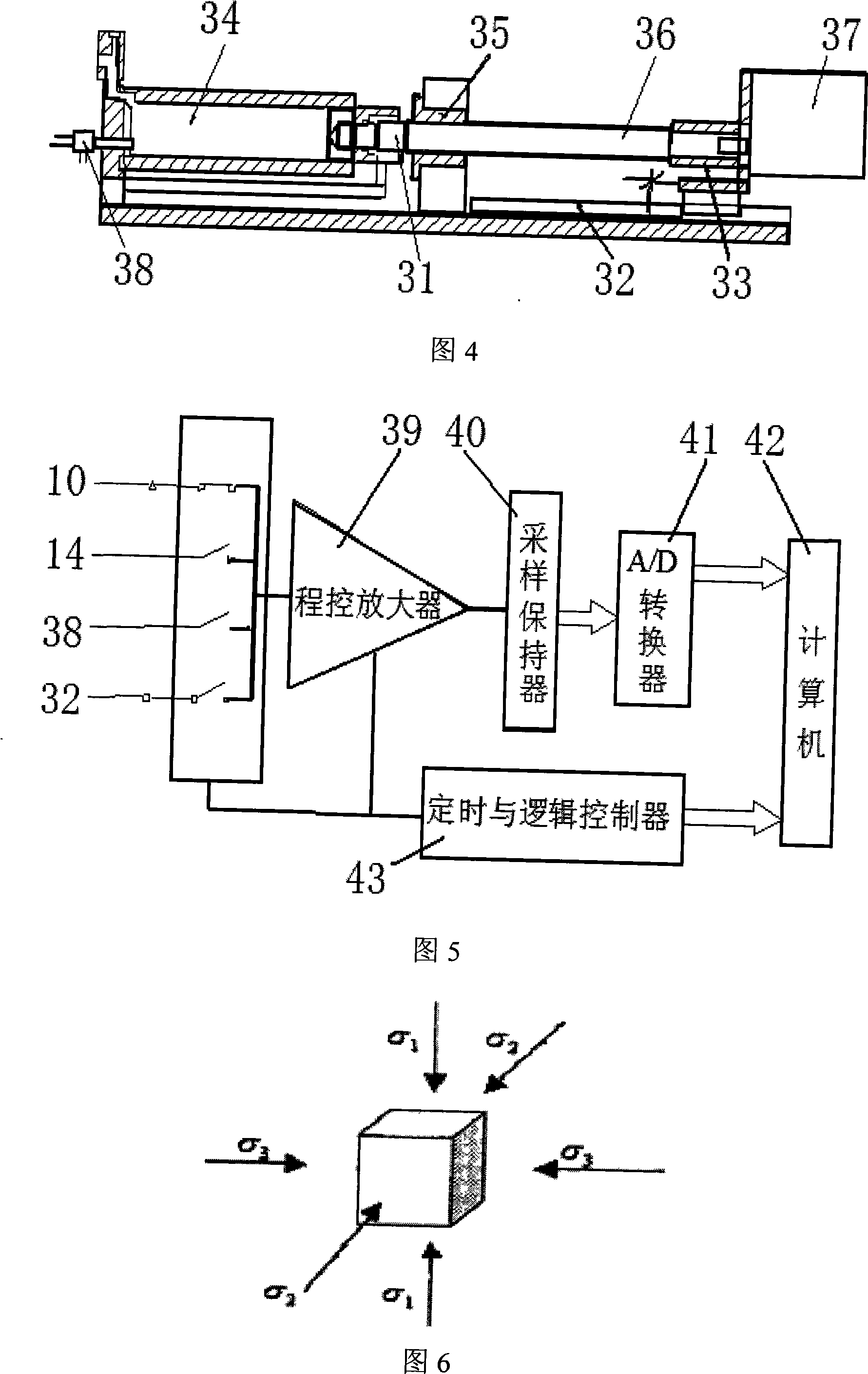

[0020] The invention includes a main engine part, a hydraulic load control part, and a measurement signal acquisition and processing part. Among them, the main engine is the core to realize the stress on the cube sample and control the drainage conditions; the hydraulic load control part applies the load through the stepping motor to drive the pressurization system mechanism; the measurement signal acquisition and processing part controls the signal input and the output of the sensor measurement signal Automatic control can automatically control the vertical stress and lateral stress.

[0021] As shown in FIG. 1 , it is a schematic diagram of the structure of the host computer according to the embodiment of the present invention. It consists of a fine adjustment handle 2 and a coarse adjustment handle 11 installed on the base 1 of the main m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com