Joint tool and method for flexible printed circuit board

A technology for flexible printing and laminating fixtures, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as reducing the efficiency of hot presses, difficult to control the amount of glue overflowing, and prolonging the time of the pressing process. , to improve the efficiency, reduce the false lamination process, not easy to stick and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

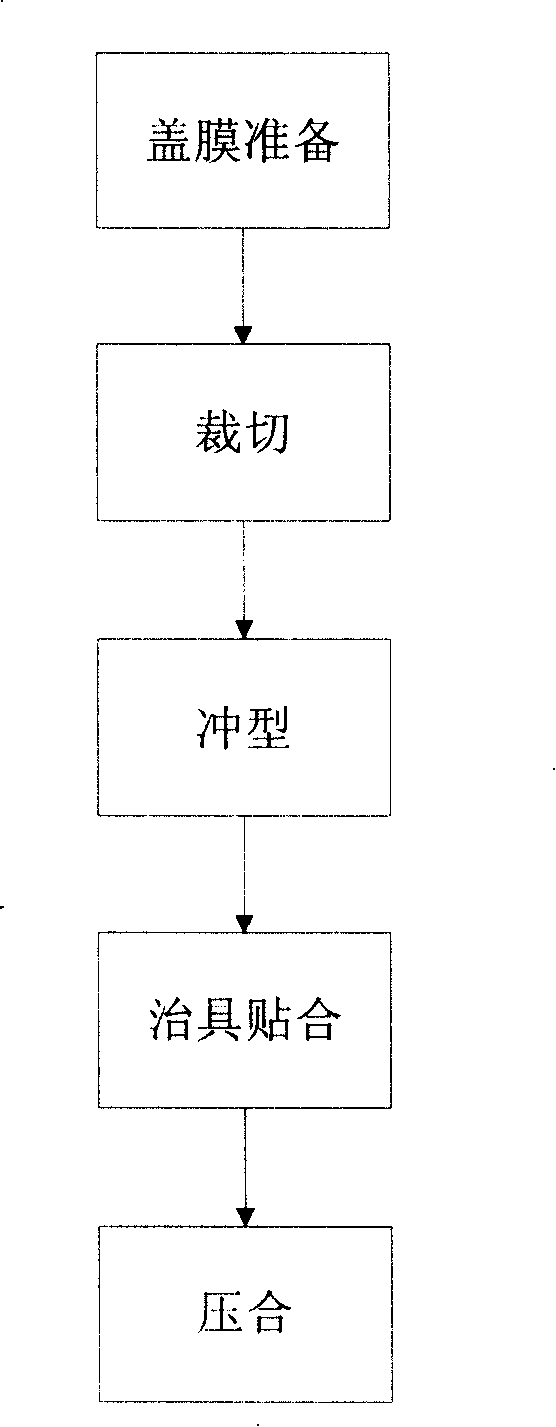

Method used

Image

Examples

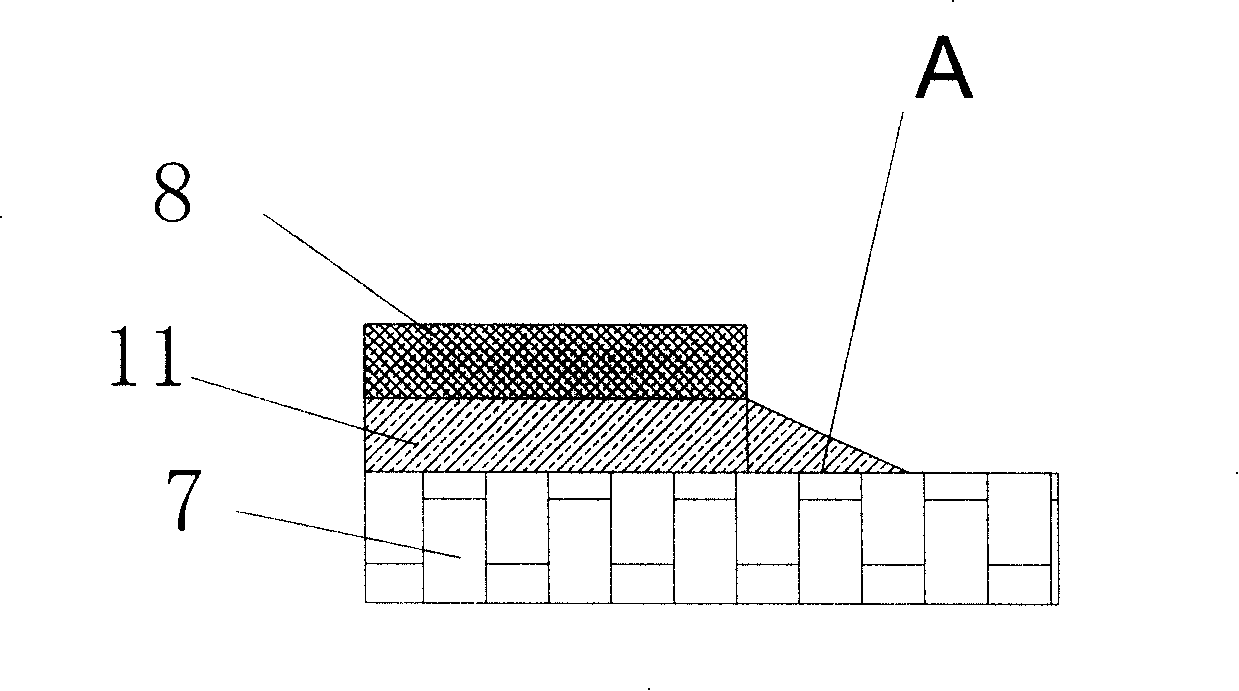

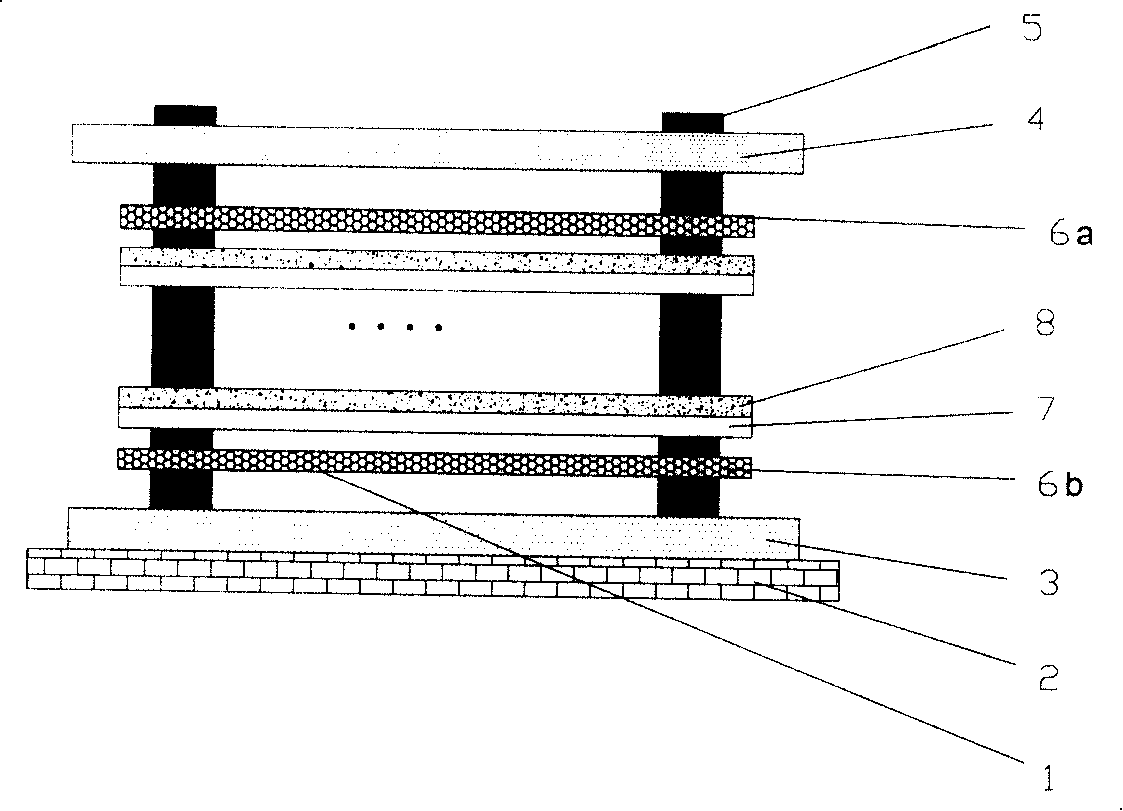

Embodiment 1

[0077] Embodiment 1, the jig bottom plate 2 , the jig support plate 3 and the jig top cover plate 4 in the single-sided flexible printed circuit board bonding jig 1 are all made of FR4 material. The upper and lower separation membranes (6a, 6b) use polypropylene membrane material with a thickness of 50um. After the circuit is formed, the diameters of the bonding positioning holes on the copper foil 7 and the covering film 8 are both 2.0mm. The jig pin 5 is made of steel with a diameter of 1.97 mm. The bonding level of the product is 15 layers, and the base film of the cover film material is polyimide, with a thickness of 25um; the adhesive 11 of the cover film is epoxy resin, with a thickness of 25um. After bonding, the temperature of the baking process in step 5 is 100° C., and the baking time is 20 minutes, and then the bonding is performed in step 6 of the hot pressing process.

Embodiment 2

[0078] Embodiment 2, the jig bottom plate 2 , the jig supporting plate 3 and the jig top cover plate 4 in the single-sided flexible printed circuit board bonding jig 1 are all made of steel. The upper and lower separation membranes (6a, 6b) use TPX material with a thickness of 50um. After the circuit is formed, the diameters of the bonding positioning holes on the copper foil 7 and the covering film 8 are both 2.0mm. The jig pin 5 is made of steel with a diameter of 1.97mm. The bonding level of the product is 15 layers, and the base film of the cover film material is polyimide, with a thickness of 25um; the adhesive 11 of the cover film is epoxy resin, with a thickness of 25um. After bonding, the baking temperature in step 5 is 100° C. and the baking time is 20 minutes, and then the bonding is performed in step 6 in the hot pressing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com