Opening and closing device for mould and mould using the same

A shutter and mold technology, applied in the field of molds, can solve the problems of wear, insufficient closing force, unable to provide delayed mold opening effect, etc., and achieve the effects of improving service life, improving stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings.

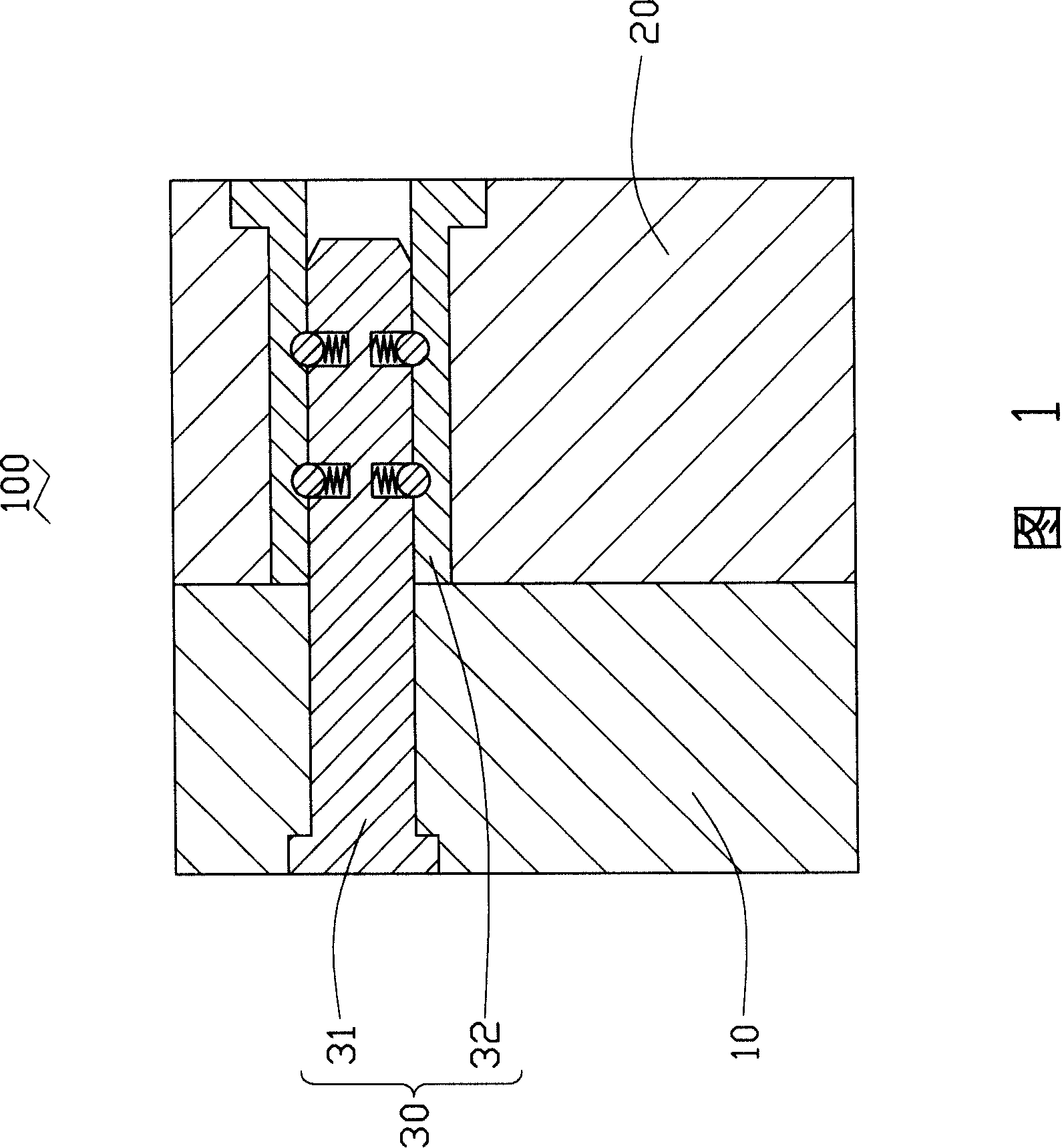

[0012] Referring to FIG. 1 , a mold 100 provided by an embodiment of the present invention includes a male template 10 , a female template 20 and at least one shutter 30 . The shutter 30 is used to delay mold opening between the male template 10 and the female template 20 . The shutter 30 includes a guide pin 31 and a guide pin bushing 32 .

[0013] The guide pin 31 can be fixed on the fixed plate (not shown) on the male template 10 side or be fixed on the male template 10, when the guide pin 31 is fixed on the male template 10, the guide pin 31 can be connected with the male template 10 made into an integral structure. In this embodiment, the guide pin 31 is fixed on a fixing plate (not shown) on one side of the male template 10 , and the guide pin bushing 32 is fixed on the female template 20 .

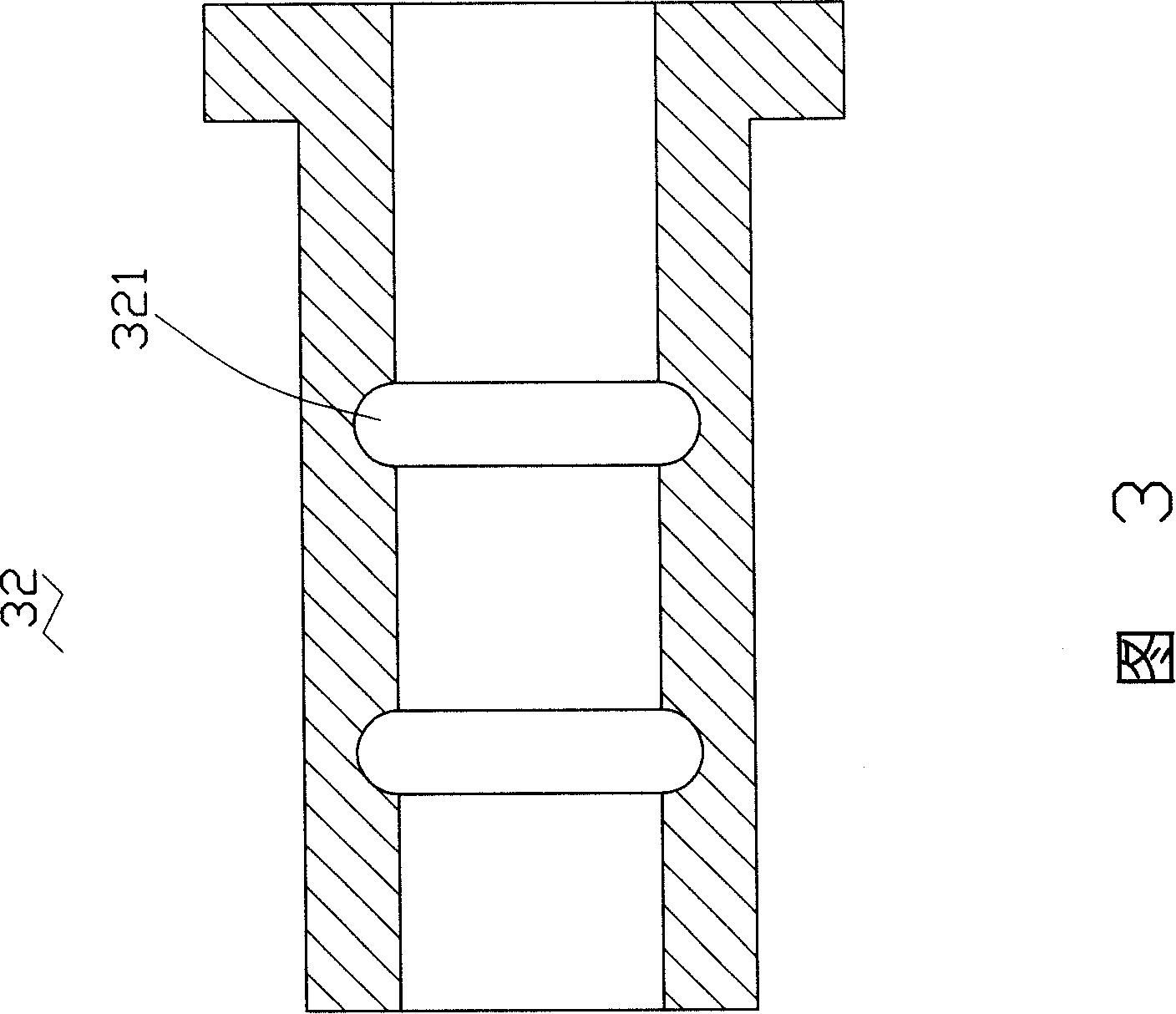

[0014] Please refer to Fig. 2, described guide pin 31 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com