Minisize photography module and substrates thereof

A substrate and miniature technology, applied in the direction of TV, color TV, electrical components, etc., can solve the problems of image shift, unable to independently check the sensing area, etc., and achieve the effect of avoiding image shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

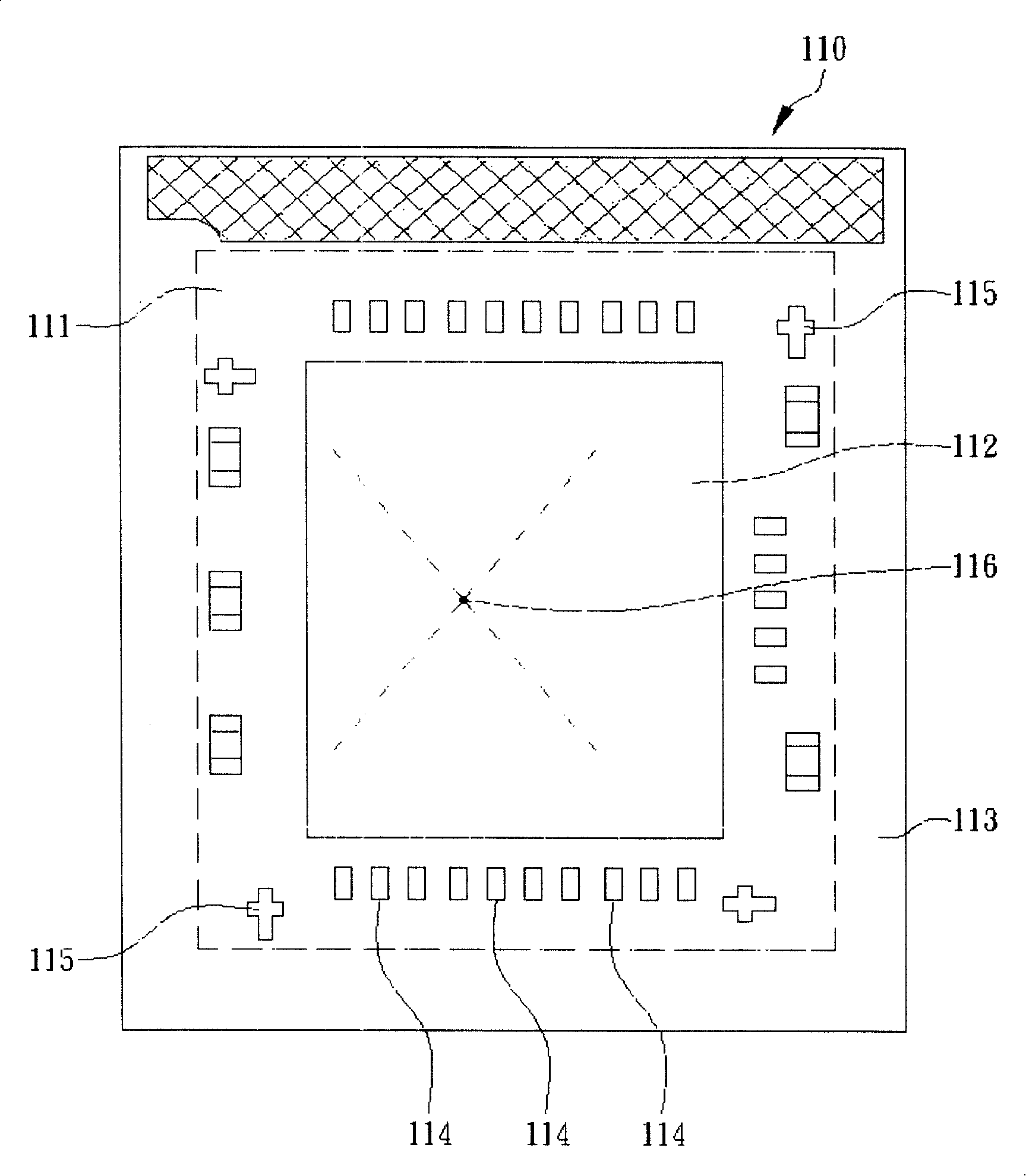

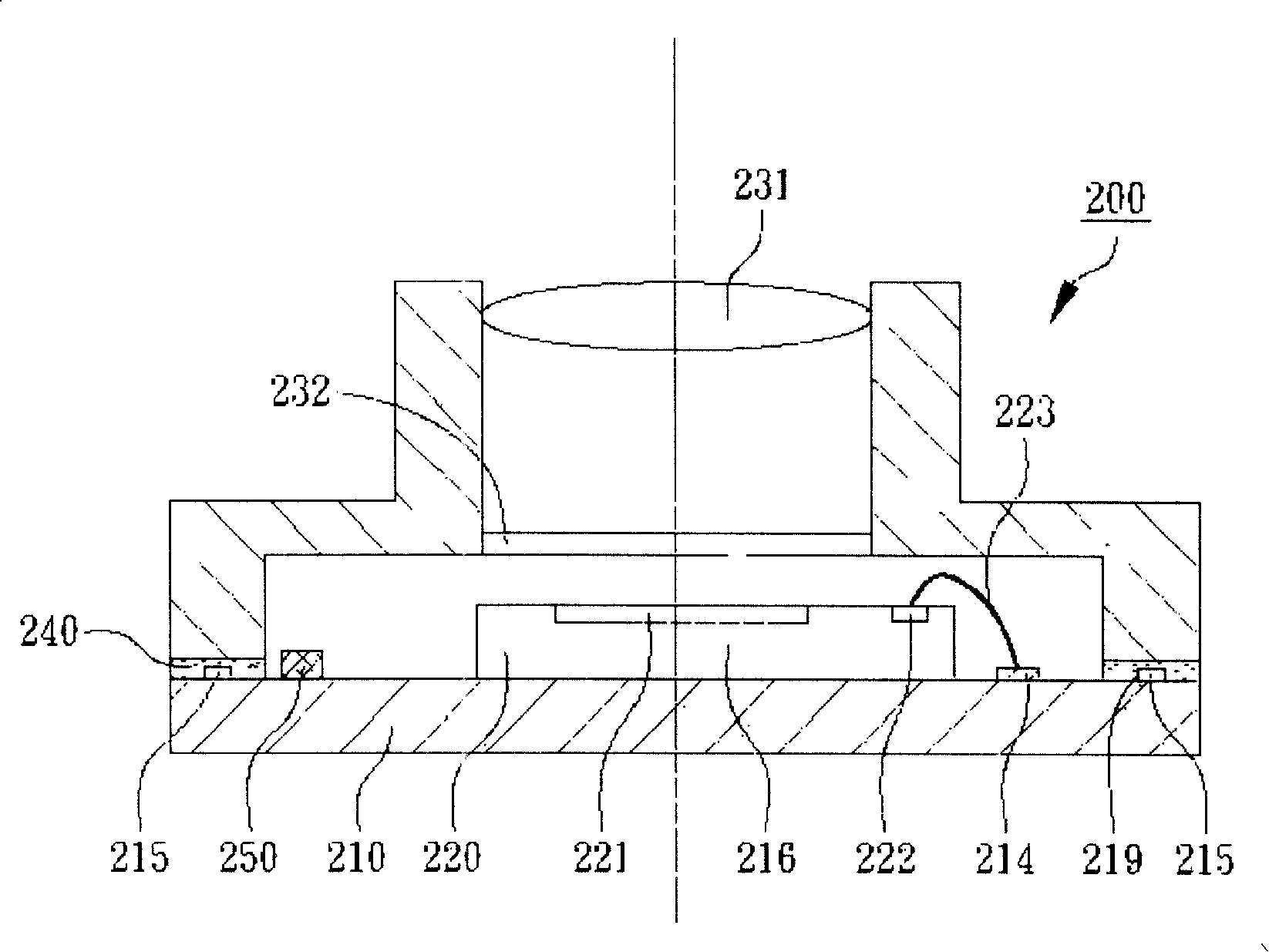

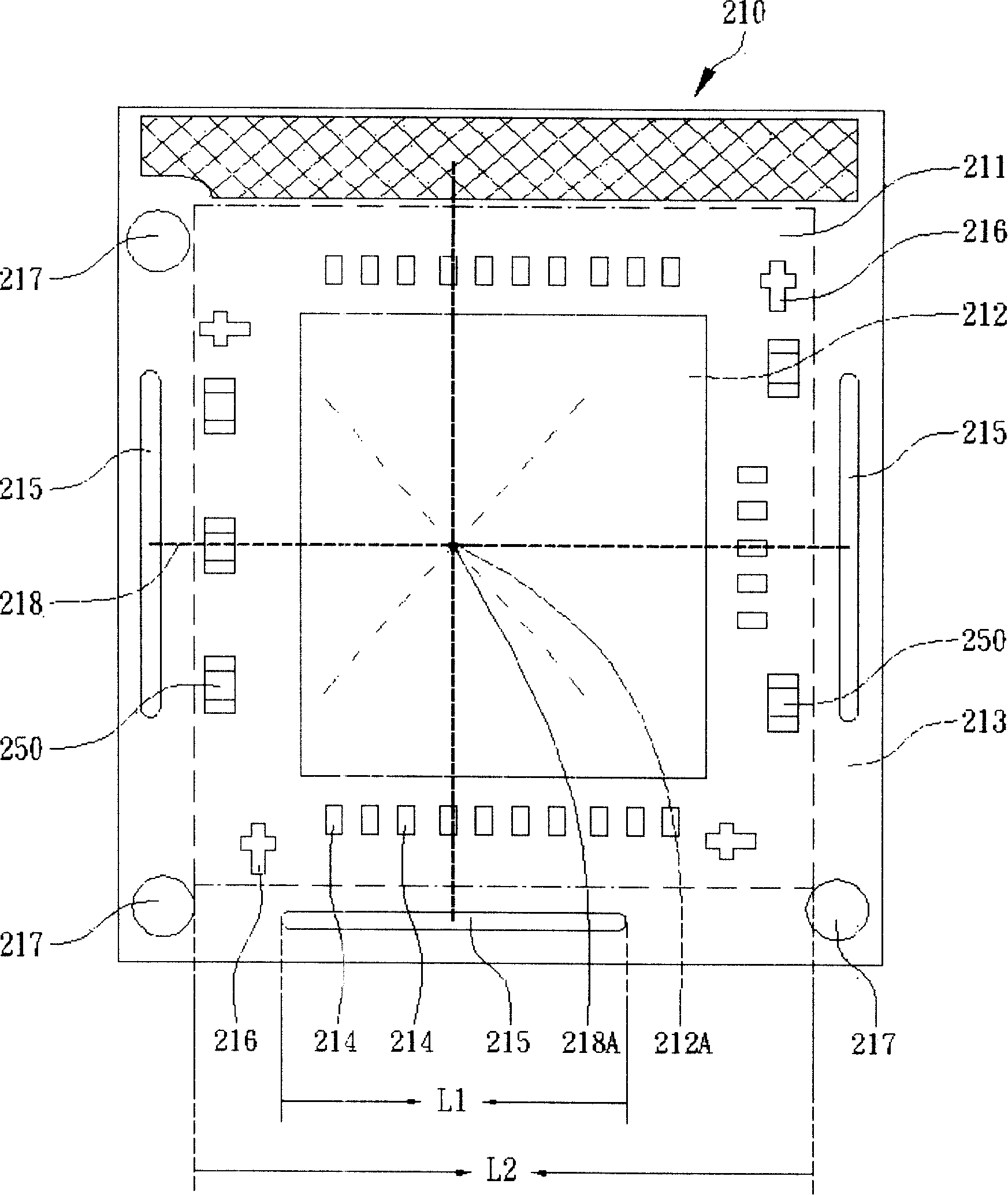

[0023] In a specific embodiment of the present invention, figure 2 is a schematic cross-sectional view of the micro-camera module, image 3 It is a schematic diagram of the upper surface of the substrate of a micro-camera module, Figure 4 is a schematic diagram of the upper surface of the substrate after die bonding.

[0024] Such as figure 2 As shown, the micro camera module 200 mainly includes a substrate 210, a sensor chip 220 and a lens module 230, the substrate 210 is used as a chip carrier, the sensor chip 220 and the lens module 230 are arranged on a surface 211 of the substrate 210 . In this embodiment, the sensor chip 220 can be a CMOS image sensor chip, which has a sensing region 221 that can accept an image and a plurality of bonding pads 222 . The lens module 230 is provided with a lens 231 and a filter 232 . In addition, a plurality of passive components 250 can be disposed on the surface 211 of the substrate 210 .

[0025] Such as image 3 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com