Method for producing clean gasoline

A gasoline and clean technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problem of large octane loss and achieve low octane loss, good adaptability, and multi-operation flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

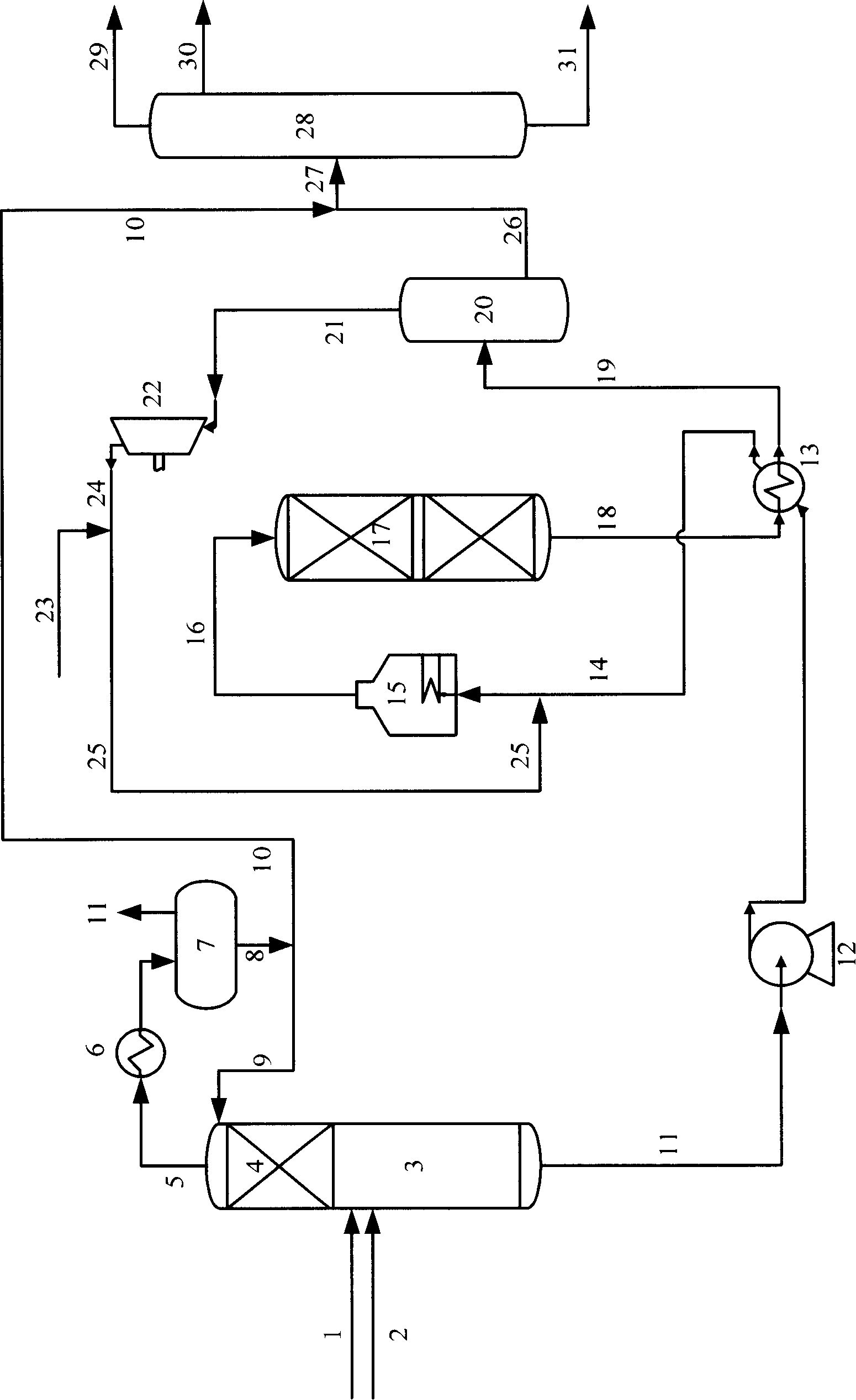

[0014] By the above composition of my country's gasoline pool, in-depth analysis and understanding of the group composition, olefin and sulfur-containing compound distribution of FCC gasoline, the specific implementation mode of the present invention is:

[0015] Gasoline raw material and hydrogen enter the tower from the middle of the catalytic distillation tower for fractionation, and fractionate into light and heavy fractions. The fractionated light gasoline fraction passes through the upper catalyst bed of the catalytic distillation tower together with hydrogen, and is carried out under the action of a hydrofining catalyst. Hydrodemercaptan reaction to obtain hydrogenated light gasoline fraction, the reaction conditions of the catalytic distillation tower are: pressure 0.5-3.0MPa, catalyst bed reaction temperature 150-300°C, liquid hourly space velocity 3-10h -1 、Hydrogen oil volume ratio 200~1000Nm 3 / m 3 .

[0016] The heavy gasoline fraction flowing out from the botto...

Embodiment 1

[0044] A catalytically cracked gasoline is used as feedstock A, and its feedstock properties are shown in Table 1. After the raw material oil A is mixed with hydrogen, it enters the tower from the middle of the catalytic distillation tower for fractionation, and the distilled light gasoline fraction passes through the upper catalyst bed of the catalytic distillation tower together with hydrogen, and undergoes hydrodesulfurization under the action of the hydrofining catalyst E Alcohol reaction to obtain a hydrogenated light gasoline fraction; the heavy gasoline fraction flowing out from the bottom of the catalytic distillation tower enters a fixed-bed hydrogenation reactor together with hydrogen, and undergoes hydrogenation under the action of a hydrofinishing catalyst D and an octane recovery catalyst F For reactions such as desulfurization, hydrodenitrogenation, olefin saturation, and octane recovery, the reaction effluent is cooled and separated to obtain a hydrogenated heavy...

Embodiment 2

[0047] A catalytically cracked gasoline is used as feedstock B, and its feedstock properties are shown in Table 1. After the raw material oil B is mixed with hydrogen, it enters the tower from the middle of the catalytic distillation tower for fractionation, and the fractionated light gasoline fraction passes through the upper catalyst bed of the catalytic distillation tower together with hydrogen, and undergoes hydrodesulfurization under the action of the hydrofining catalyst E Alcohol reaction to obtain hydrogenated light gasoline fraction; the heavy gasoline fraction flowing out from the bottom of the catalytic distillation tower enters the fixed bed hydrogenation reactor together with hydrogen, and undergoes hydrodesulfurization and hydrodenitrogenation under the action of hydrogenation reforming catalyst G , olefin saturation and octane number recovery, etc., the reaction effluent is cooled and separated to obtain hydrogenated heavy gasoline fraction; the obtained hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com