Roller abrasion mathematical model optimizing method for improving CSP product quality

A mathematical model and optimization method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of poor shape quality, large difference, affecting the production of high-proportion thin-gauge hot-rolled sheets, etc., to achieve enhanced Stabilizing, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 comprises the steps:

[0024] (1) First of all, it is single-stream production, and the parameter values of the mathematical model of roll wear selected by each stand are shown in Table 4.

[0025] Table 4 Parameter values of the mathematical model of roll wear in each stand

[0026] rack

[0027] (2) After a period of time, single-stream production is transformed into dual-stream production. The parameter values of the mathematical model of roll wear selected by each stand are automatically converted from single-stream data to dual-stream data. The parameter values of the mathematical model of roll wear for each stand are shown in Table 5. Show.

[0028] Table 5 Parameter values of the mathematical model of roll wear in each stand

[0029] rack

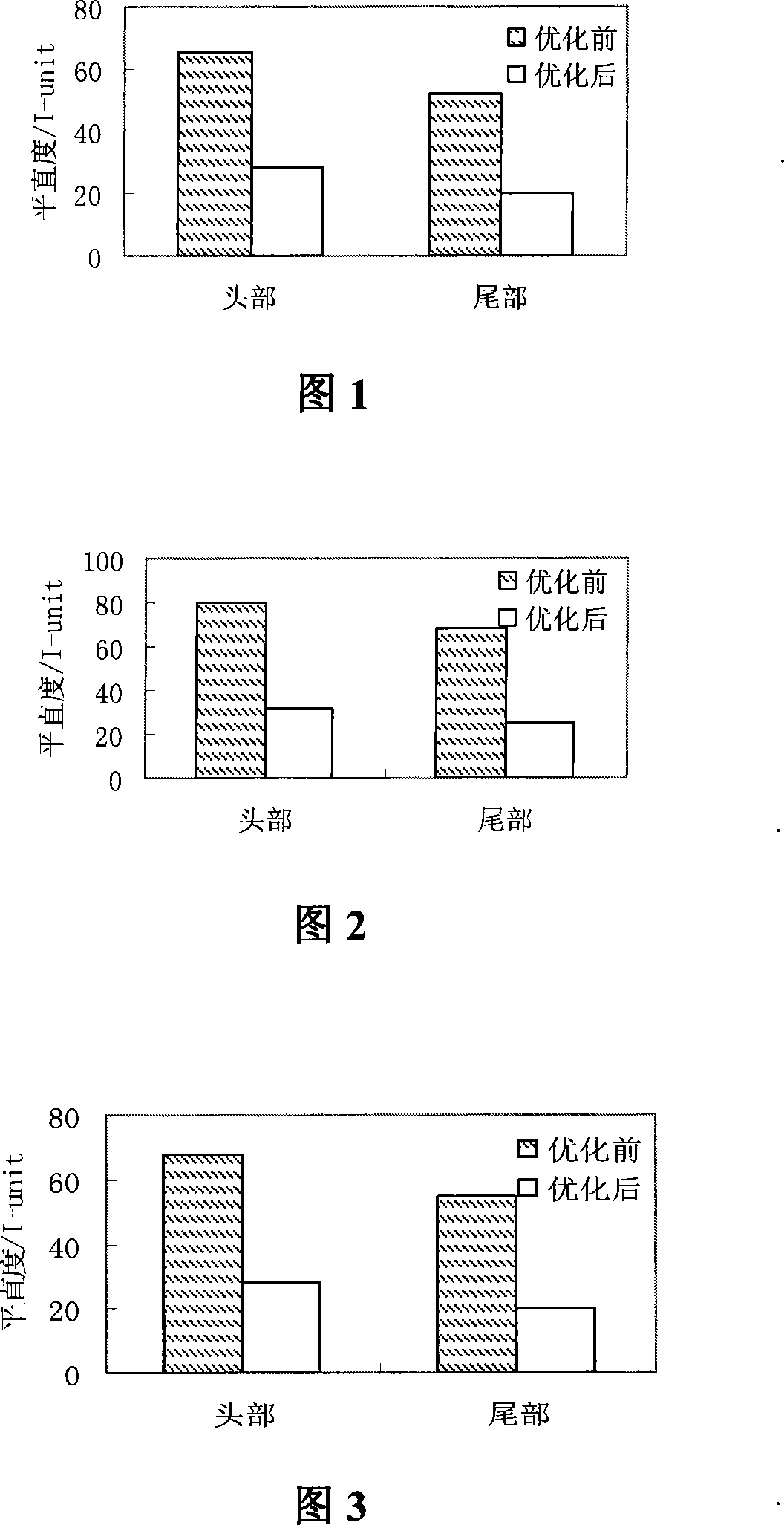

[0030] In Example 1, the rolling steel type is SPA-H, the specification is 1.6×1180mm, the weight of a single coil is 20 tons, and the statistical data is 100 coils. shown. It can...

Embodiment 2

[0031] Embodiment 2 is another embodiment of the present invention, and the relevant differences between this embodiment and Embodiment 1 specifically include the following aspects:

[0032] (1) The first is double-flow production, and the parameter values of the mathematical model of roll wear selected by each stand are shown in Table 6.

[0033] Table 6 Parameter values of the mathematical model of roll wear in each stand

[0034] rack

[0035] (2) After a period of time, the double-stream production is transformed into single-stream production. The parameter values of the mathematical model of roll wear degree selected by each stand are automatically converted from the double-stream data to the parameters of the single-stream model. The parameter values of the mathematical model of roll wear for each stand are shown in the table 7.

[0036] Table 7 Parameter values of the mathematical model of roll wear in each stand

[0037] rack

[0038] In...

Embodiment 3

[0039] Embodiment 3 is the 3rd embodiment of the present invention, and the relevant difference in this embodiment and embodiment 1 and embodiment 2 specifically includes the following aspects:

[0040] (1) The first is double-stream production, and the parameter values of the mathematical model of roll wear selected by each stand are shown in Table 8.

[0041] Table 8 Parameter values of the mathematical model of roll wear in each stand

[0042] rack

[0043] (2) After a period of time, the double-stream production is transformed into single-stream production. The parameter values of the mathematical model of roll wear degree selected by each stand are automatically converted from the double-stream data to the parameters of the single-stream model. The parameter values of the mathematical model of roll wear for each stand are shown in the table 9.

[0044] Table 9 Parameter values of the mathematical model of roll wear in each stand

[0045] rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com