Cleaning process for outer cooling shift gas alkali preparation

A technology for changing gas and process, which is applied in bicarbonate preparation, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of high gas velocity in the cleaning tower, increase in system pressure drop, and affect normal production, so as to improve the operation rate , Cleaning operation is simple, and the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

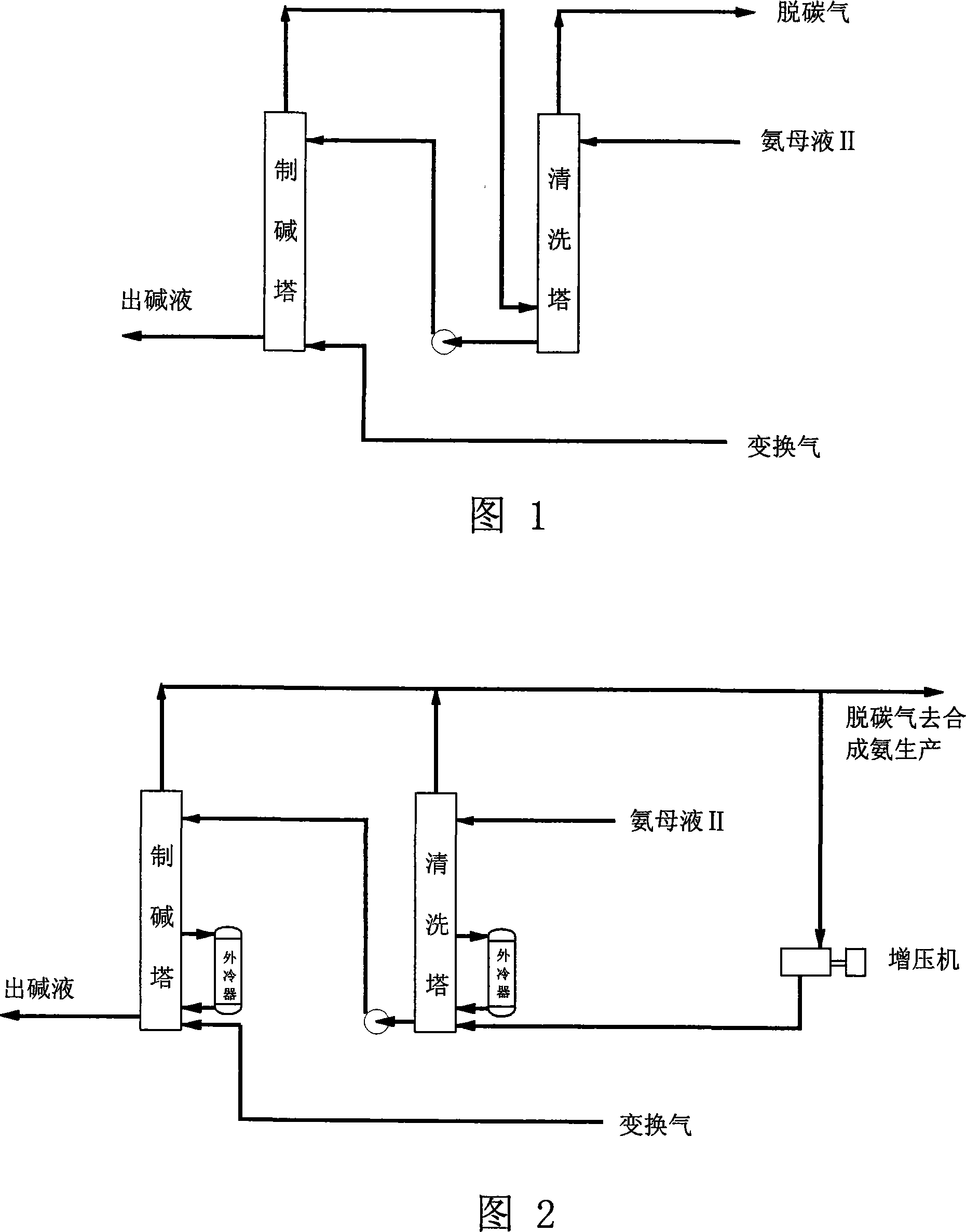

[0020] This embodiment is the cleaning process of an external cooling shift gas alkali-making device with an annual output of 200,000 tons of heavy alkali, and its schematic flow chart is as shown in Figure 2:

[0021] Connect 4 external cooling carbonization towers with a diameter of φ2800 / 3800 in parallel to form a group. Each carbonization tower is connected to a group (3 sets) of external coolers. Each carbonization tower is cleaned in rotation after 3 days of operation. The carbonization tower to be cleaned and The external coolers connected to it are cleaned at the same time; during the cleaning period, other soda making towers except the cleaning tower continue to make soda, that is, 3 soda making and 1 cleaning; the soda making time of each carbonizing tower is about 72 hours, and the cleaning time About 24 hours.

[0022] During cleaning, the ammonia mother liquor II of about 35-37°C is passed into the cleaning tower, and at the same time, part of the carbonized tail ...

Embodiment 2

[0025] In this embodiment, the schematic diagram of the process flow diagram for the cleaning process of alkali-making by changing the cold gas is as shown in Figure 2:

[0026] Connect 5 external cooling carbonization towers with a diameter of φ3200 / φ4800 in parallel to form a group. Each carbonization tower is connected to a group (4 sets) of external coolers. Each carbonization tower is cleaned in rotation after 4 days of operation. The carbonization tower to be cleaned It is cleaned at the same time as the external coolers connected to it; during the cleaning period, other soda making towers except the cleaning tower continue to make soda, that is, 4 soda making and 1 cleaning; the soda making time of each carbonizing tower is about 96 hours, cleaning The time is about 18 hours.

[0027] The cleaning method is basically the same as in Example 1, that is, the ammonia mother liquor II of about 40-42 ° C is passed into the cleaning tower, and the partially carbonized tail gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com