A calibrated microelectromechanical microphone

一种话筒、话筒组件的技术,应用在电气元件、换能器电路、半导体静电换能器等方向,能够解决性能参数影响、成本低、很难消除影响等问题,达到紧凑配置、增加生产产量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

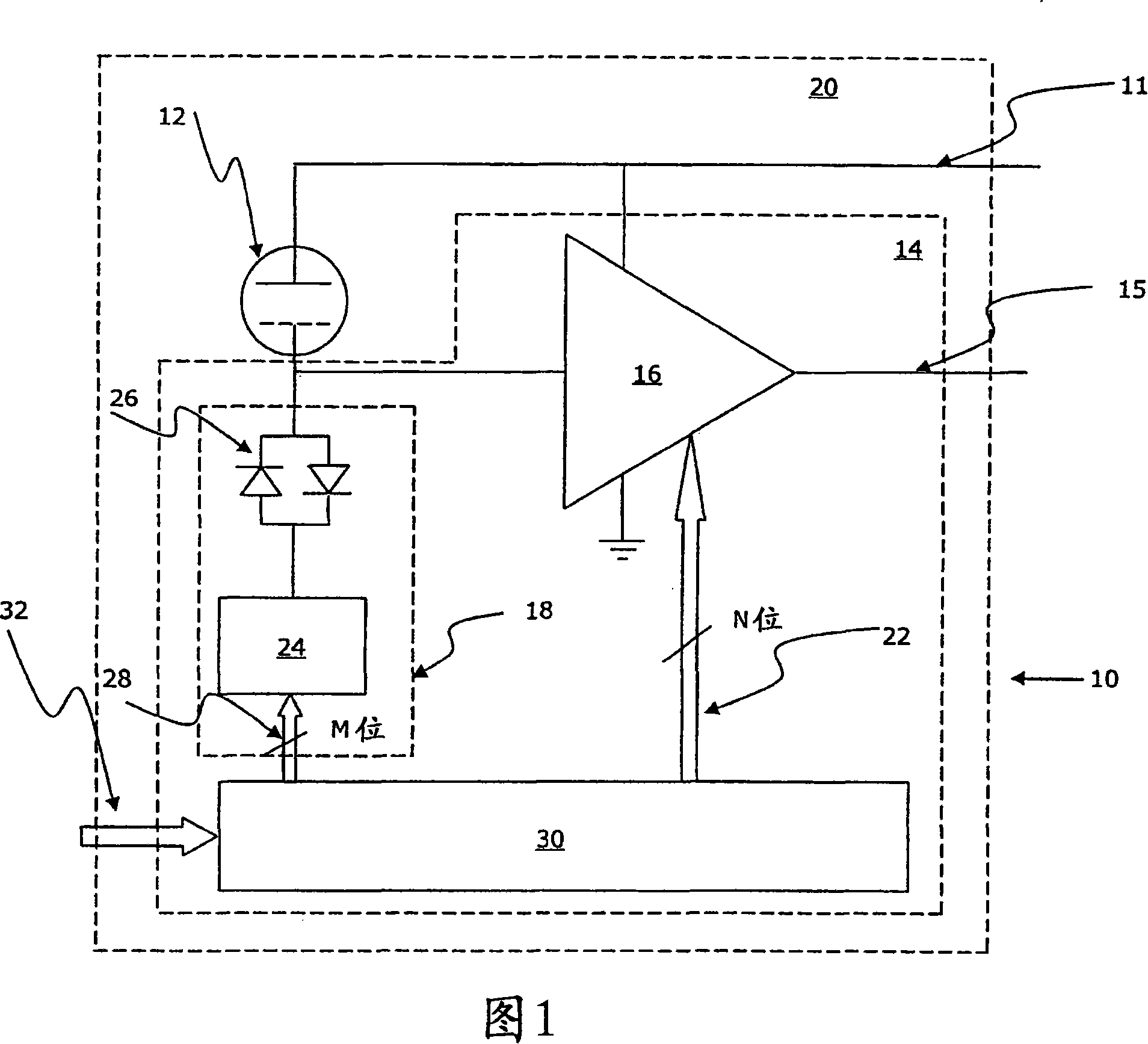

[0086] A microphone 10 according to a preferred embodiment of the present invention comprises a MEMS condenser microphone 12 and an integrated circuit portion 14 which includes a microphone (pre)amplifier 16, a DC bias generator 18, and is built into a microphone housing / package 20 middle.

[0087] Furthermore, the microphone has a voltage source 11 and an output 15 .

[0088] The amplifier 16 includes a data input 22 for adjusting its gain, the bias voltage generator 18 includes a diode arrangement 26 and a DickSon pump 24 with a data input 28 for adjusting the voltage output of the generator 18 (for a detailed description see e.g. EP -A-1599067). The Dickson pump operates by converting the M-bit information directly into a voltage.

[0089] The gain of microphone pre-amplifier 16 is adjusted by using calibration data 22 loaded into and stored in non-volatile memory 30 of integrated circuit 14 during an initial testing step in the MEMS condenser microphone 10 manufacturing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com