Multi-function motor

A multi-functional, rotor technology, applied in the shape/style/structure of magnetic circuit, magnetic circuit characterized by magnetic materials, and stationary parts of magnetic circuit, etc. High-level problems, to achieve the effect of simple structure, easy speed regulation and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

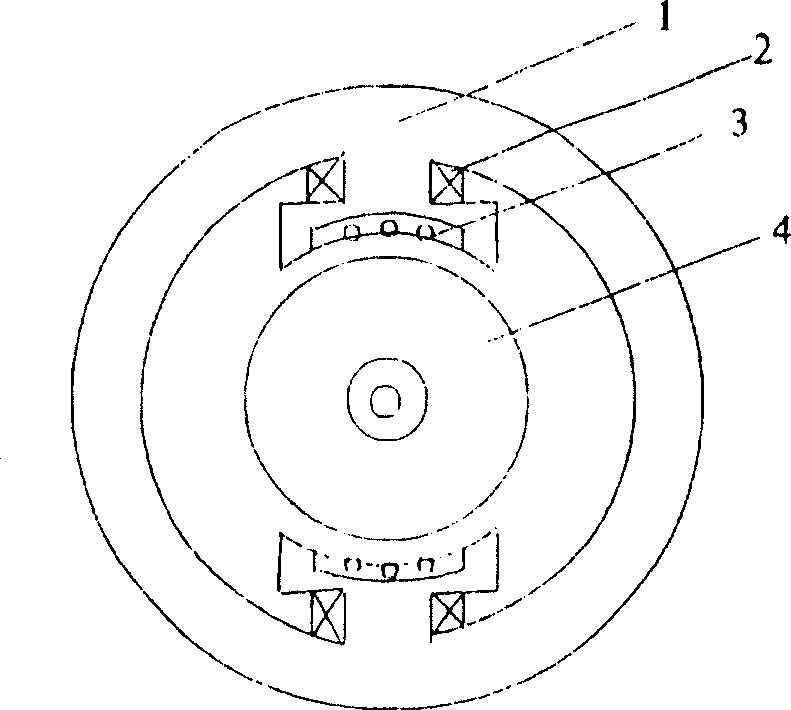

[0007] Example: A multifunctional motor. The motor is composed of a stator 1 and a rotor 4. The rotor is made of soft magnets. The stator is made of soft magnets or permanent magnets. It also includes a coil 3. The stator generates an excitation magnetic field to make the rotor Magnetization also produces a magnetic field. At this time, the rotor actually becomes a magnet with two poles. After the coil in the stator is supplied with current, it will interact with the rotor by electromagnetic force. Because the coil is fixed, the rotor has to rotate. If the core is continuous, the rotor will rotate continuously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com