Diffusing lens

A technology of concentrating sheet and diffusing surface, which is applied in the field of concentrating sheet, can solve problems such as time-consuming and easy to be found, and achieve the effect of reducing the chance of occurrence of moire, increasing the production pass rate, and improving the production pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Please refer to the accompanying drawings and embodiments for the purpose and effect of the present invention, and the detailed description is as follows.

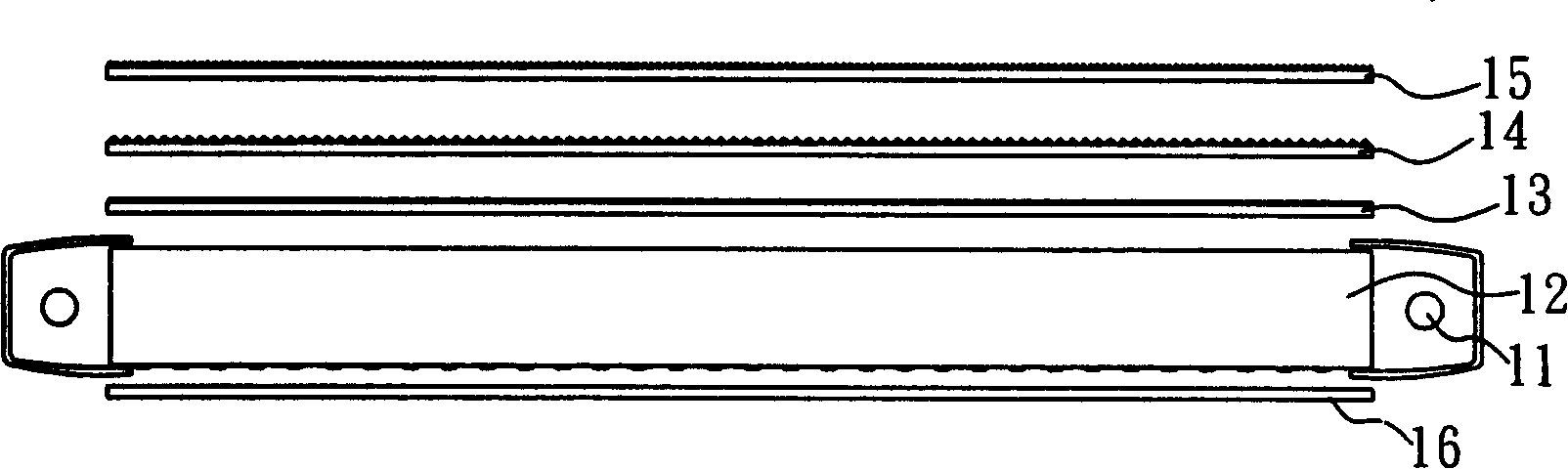

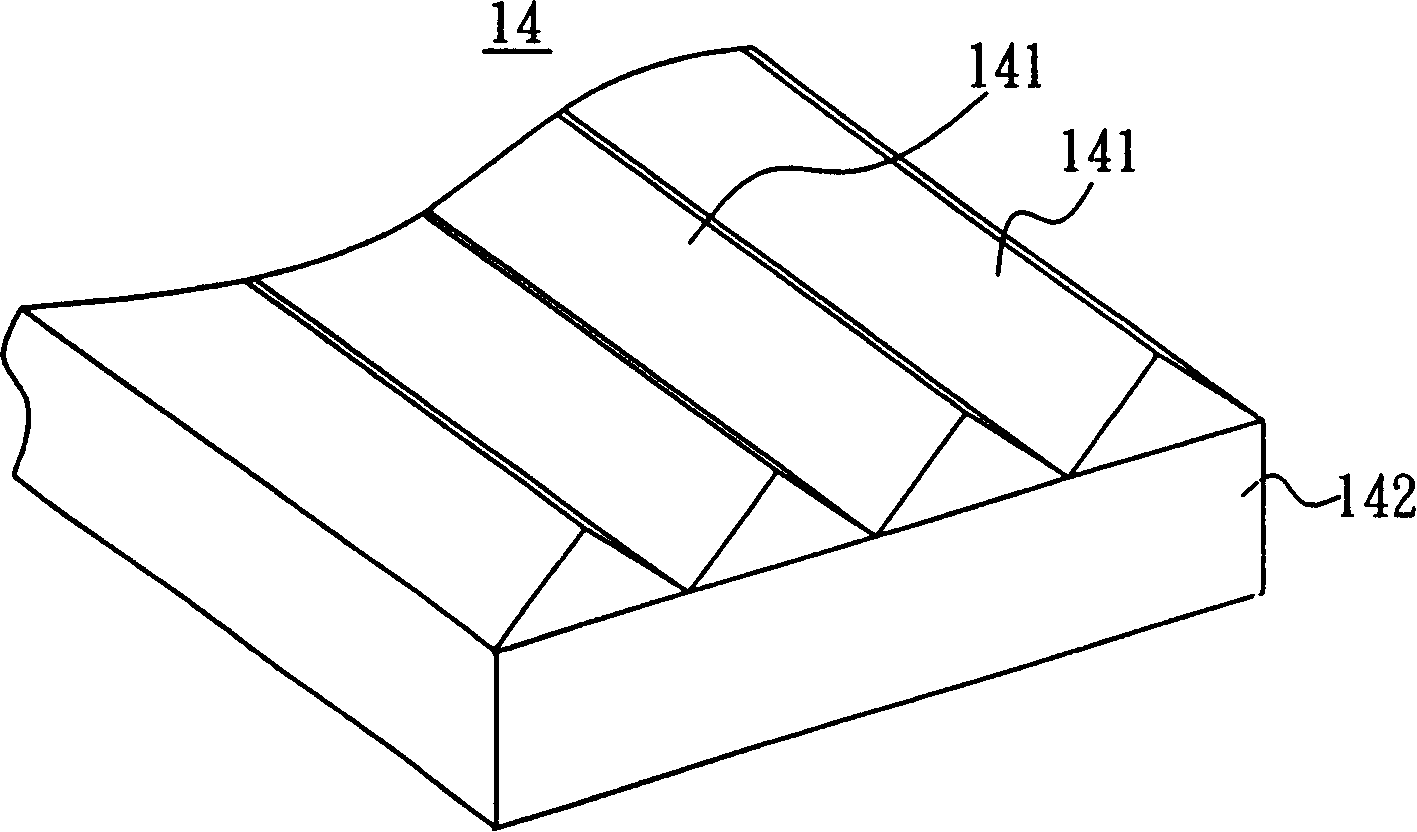

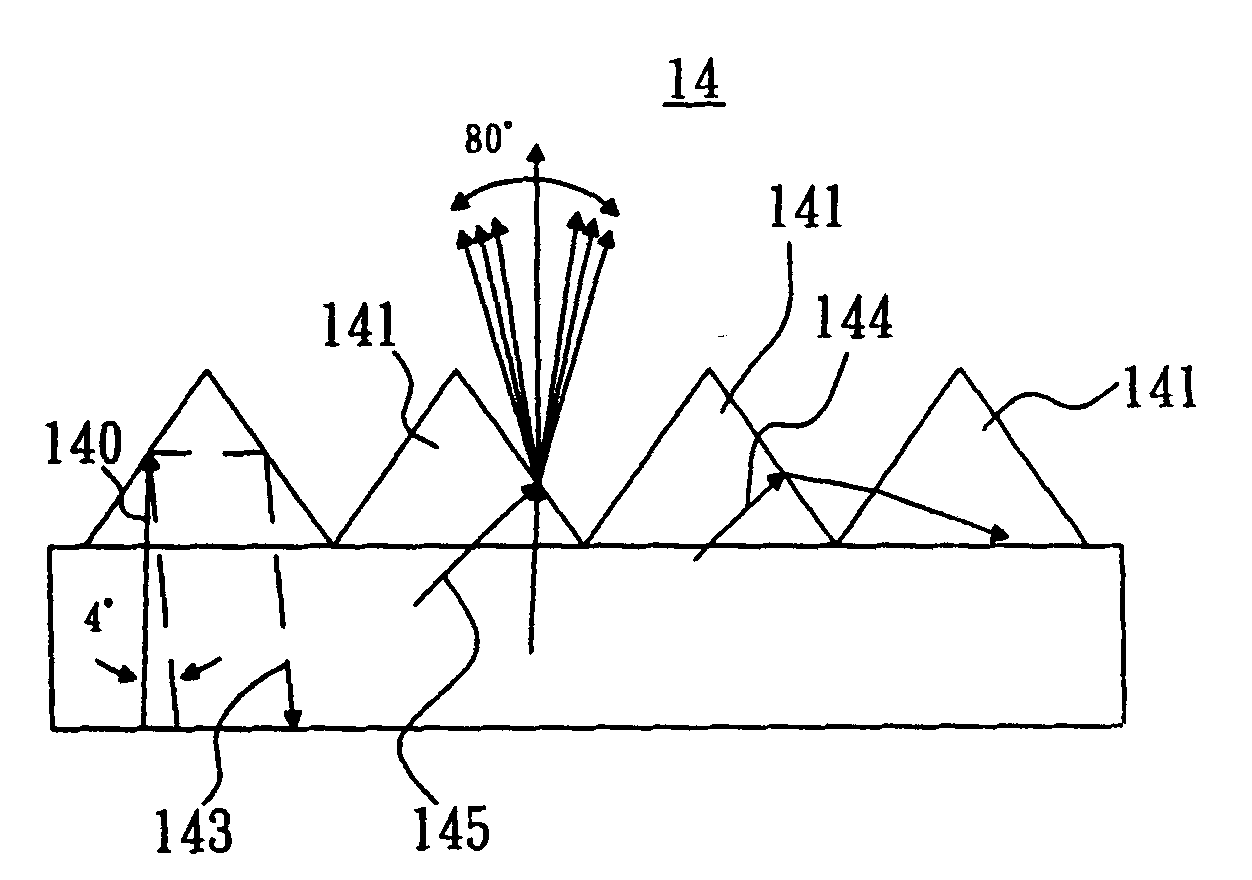

[0026] see Figure 5 , 6 , 7 shown. The light-diffusing and concentrating sheet of the present invention is used to reduce the light dispersion phenomenon of the prism column and the probability of moiré, and helps to improve the production qualification rate. The light-diffusing and concentrating sheet 30 of the embodiment of the present invention includes: a substrate 31 through which light can pass. A surface of the substrate 31 includes a plurality of longitudinally arranged elongated prism columns 32 and a plurality of elongated rough diffusion surfaces 33; at least two adjacent prism columns 32 have elongated rough diffusion surfaces 33; Each prism column 32 has a ridgeline 321, a first side 322, and a second side 323 respectively; the ridgeline 321 is placed at the highest position of the prism column 32; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com