High-efficiency impingement type hydraulic generator

A hydro-generator and impingement technology, which is applied in impingement engines, hydroelectric power generation, engine components, etc., can solve the problems of low water energy utilization rate, large water energy waste, and difficulty in normal operation of limited water sources, so as to improve the The effect of water energy utilization rate, improving economic efficiency and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

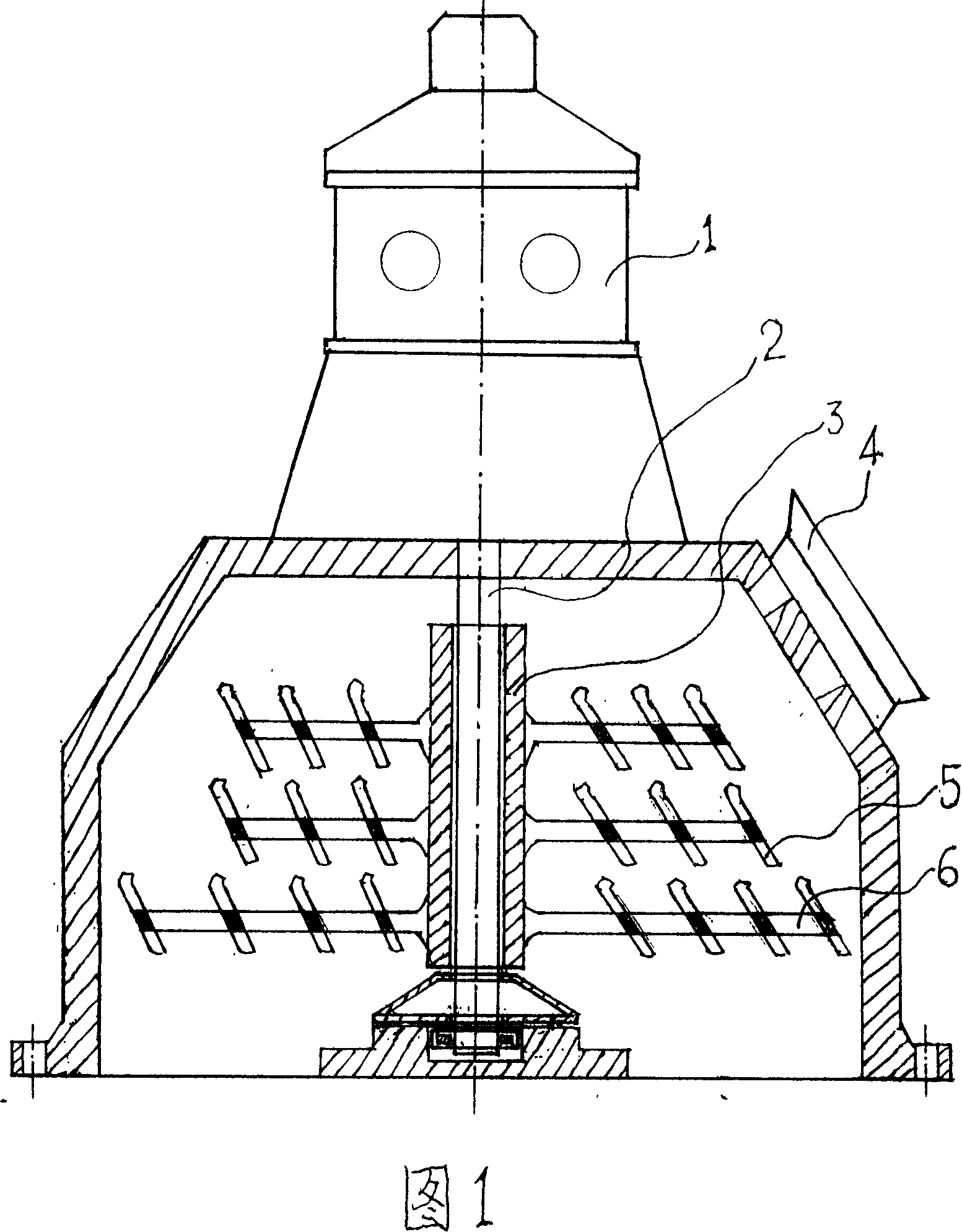

[0015] As shown in the figure, the high-efficiency impact water turbine generator includes a water wheel, a water diversion device (4) installed outside the water wheel, and a power generation device (1). Wheel shaft (2) and the wheel hub (3) with spokes (6) arranged on the wheel shaft (2), the spokes (6) are arranged at intervals around the wheel hub (3), on the wheel hub (3), from Three layers of spokes (6) are arranged at intervals from bottom to top, and the lengths of each layer of spokes (6) are inconsistent. 4 blades (5) to accept the impact of water flow, on each layer of spokes (6) thereon are provided with 3 blades (5) to accept the impact of water flow, the blade surface of the blade (5) is not perpendicular to the ground, and the upper part Inclined in the clockwise direction, that is, inclined along the direction of the impact of the water flow, the water diversion device (4) includes a water source guide channel and two primary water distribution pipes, the two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com