Ventilating current equalizer

A technology of flow equalizer and ventilation duct, which is applied in the field of uniform outflow or uniform inhalation pipeline, which can solve problems such as errors, inability to achieve uniform airflow at the tuyere, and inability to achieve uniform air supply and exhaust, etc., achieving low cost, simple structure, and convenient construction and the effect of installing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

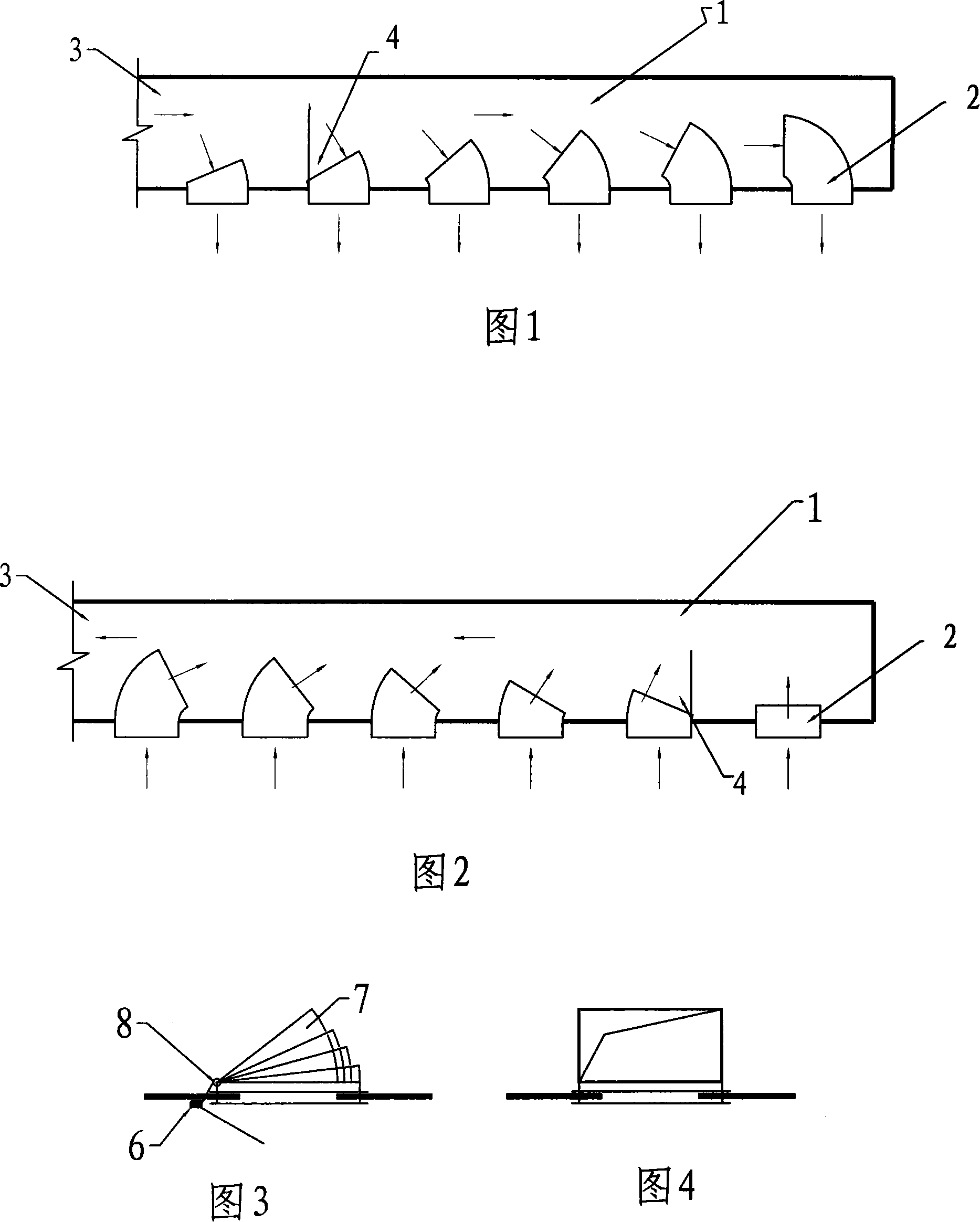

[0023] As shown in FIG. 1 , the ventilation duct 1 is an air supply duct, and the windward section on the tuyere 2 faces the starting end 3 of the duct. The projected area of the windward section of the tuyeres 2 arranged in sequence according to the starting end 3 on the cross section of the air supply duct 1 increases successively, that is, the included wind inlet angle 4 decreases successively. Each tuyere 2 intercepts the dynamic pressure in the pipe through the adjustment of the air inlet angle 4 to make up for the shortage of the outlet pressure of the tuyere until the actual demand of the outlet air volume of the tuyere is met.

[0024] As shown in Figure 2, the ventilation duct 1 is an exhaust duct, and the windward section on the tuyere 2 faces away from the starting end 3 of the duct, and the projection of the windward section on the tuyere 2 arranged in sequence according to the starting end 3 on the section of the air supply duct 1 The area decreases successively...

Embodiment 2

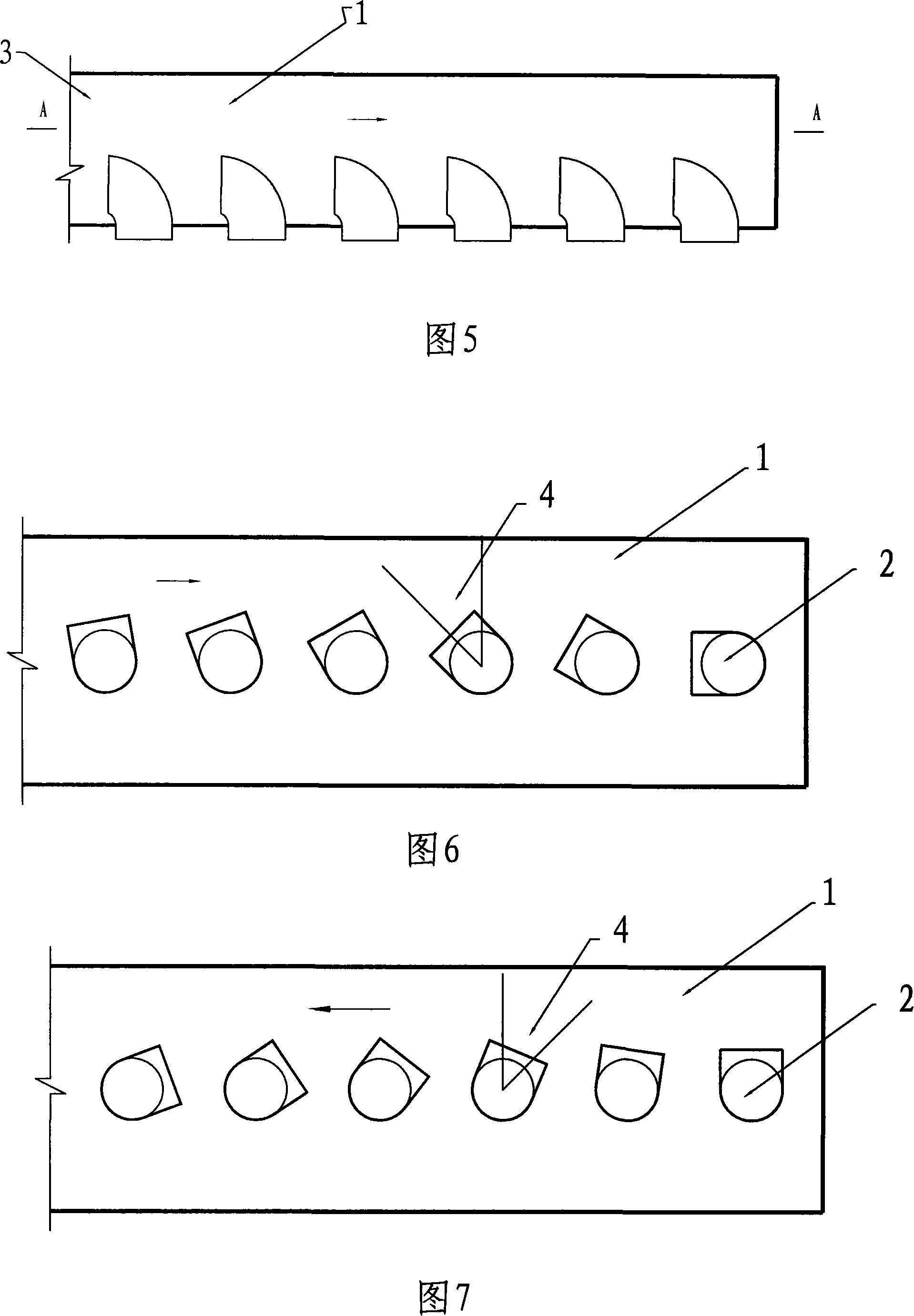

[0027] As shown in Figure 5 and Figure 6, it is another improved embodiment of the present invention. The ventilation duct 1 is a uniform air supply duct, and the tuyere 2 adjusts its windward cross section and duct cross section sequentially from the starting end 3 through its own axial rotation. The air inlet angle 4 increases sequentially to change the dynamic pressure in the intercepting pipe and keep each air outlet to obtain the same pressure to achieve uniform air flow out of the air supply pipe. When the ventilation duct 1 is an exhaust duct, as shown in FIG. 7 , the angle 4 between the windward section and the duct section is sequentially adjusted from the starting end 3 to decrease successively, so as to realize uniform suction of the uniform exhaust duct.

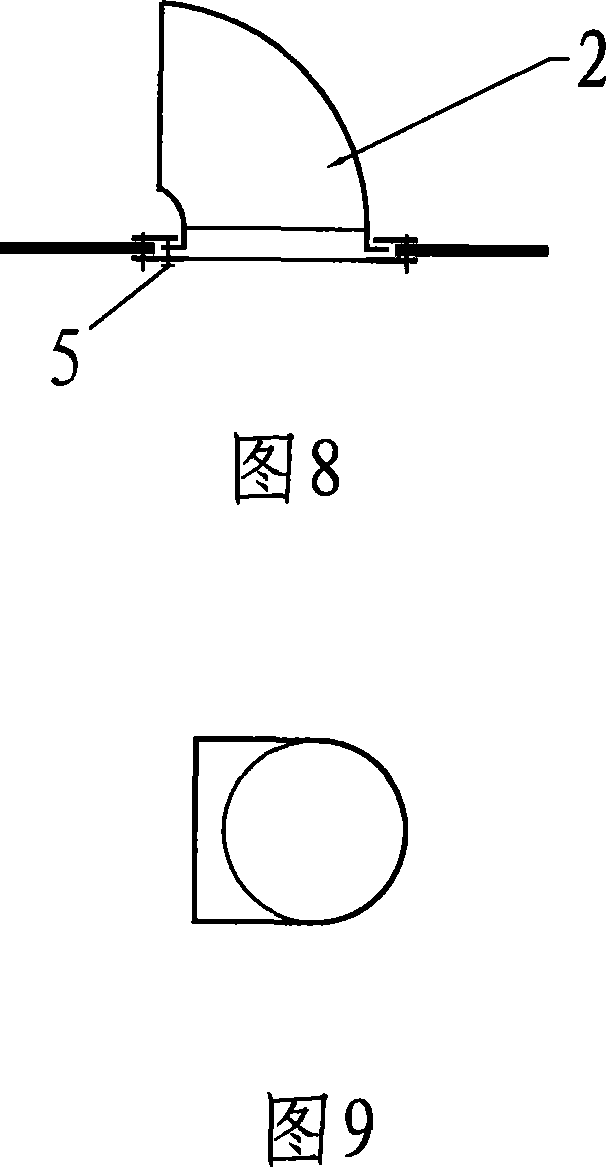

[0028] In order to facilitate the adjustment of the air inlet angle 4 of each tuyere 2, the tuyere 2 is a complete 90° circular air duct elbow, its structure and installation form are shown in Figure 8 and Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com