Certificate and card manufacturing method and system

A production method and card technology, applied to cardboard items, etc., can solve the problems of restricting card production efficiency, energy consumption, energy consumption, etc., and achieve the effects of reducing procedures, improving efficiency, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

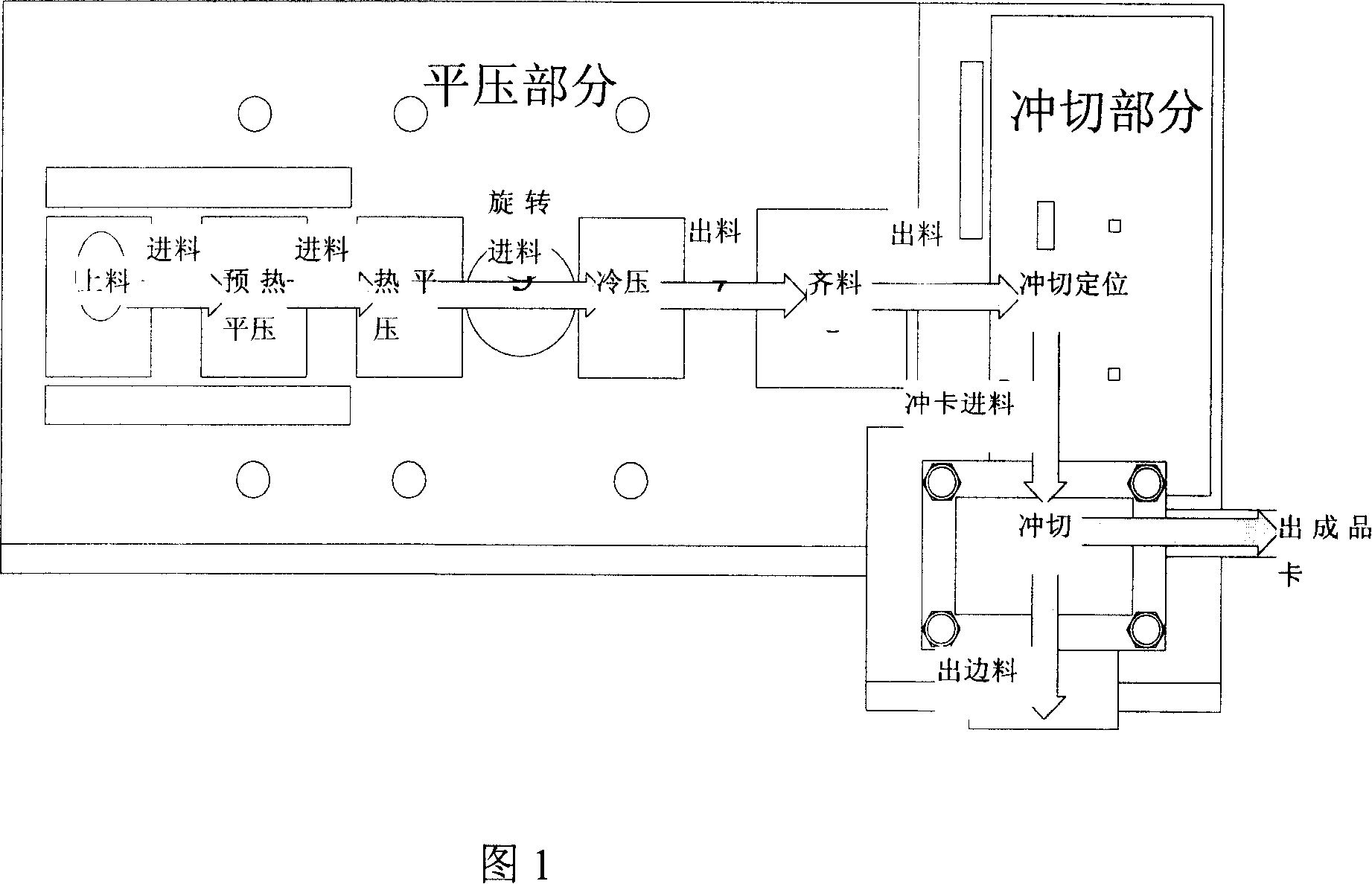

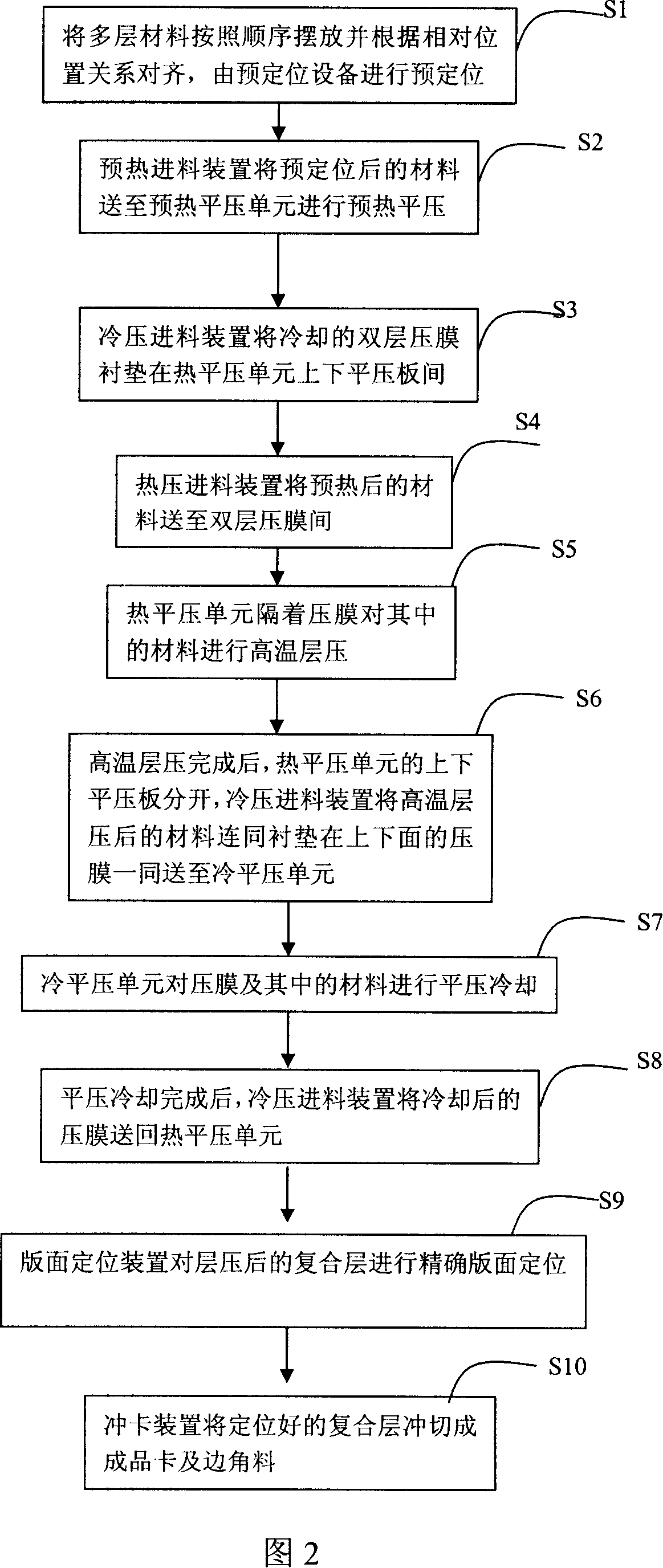

[0037] As shown in FIG. 1 , it is a schematic flow chart of the stations of the flat pressing and punching equipment of the present invention. Firstly, the pre-positioned materials are loaded into the feeding bin of the flat pressing part of the equipment, and the material is automatically loaded by the feeding system; then the feeding system sends the materials to the preheating flat pressing unit and the hot flat pressing unit in sequence, Then it is sent to the cold pressing unit by the rotary feeding device for flat pressing and cooling to form a composite layer; after cooling, the discharging device is first sent to the unloading device to find the correct position, and then sent to the punching part of the equipment . When the laminated material is sent to the punching part, the material is accurately positioned by the layout positioning device; then the material is sent to the hydraulic punching device by the punching card feeding system for punching; the punched card a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com