Base plate cleaning device

A cleaning device and substrate technology, applied in the cleaning/polishing of conductive patterns, secondary treatment of printed circuits, electrical components, etc., can solve the problems of long time consumption in cleaning steps, unfavorable increase of display capacity, and unfavorable display capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

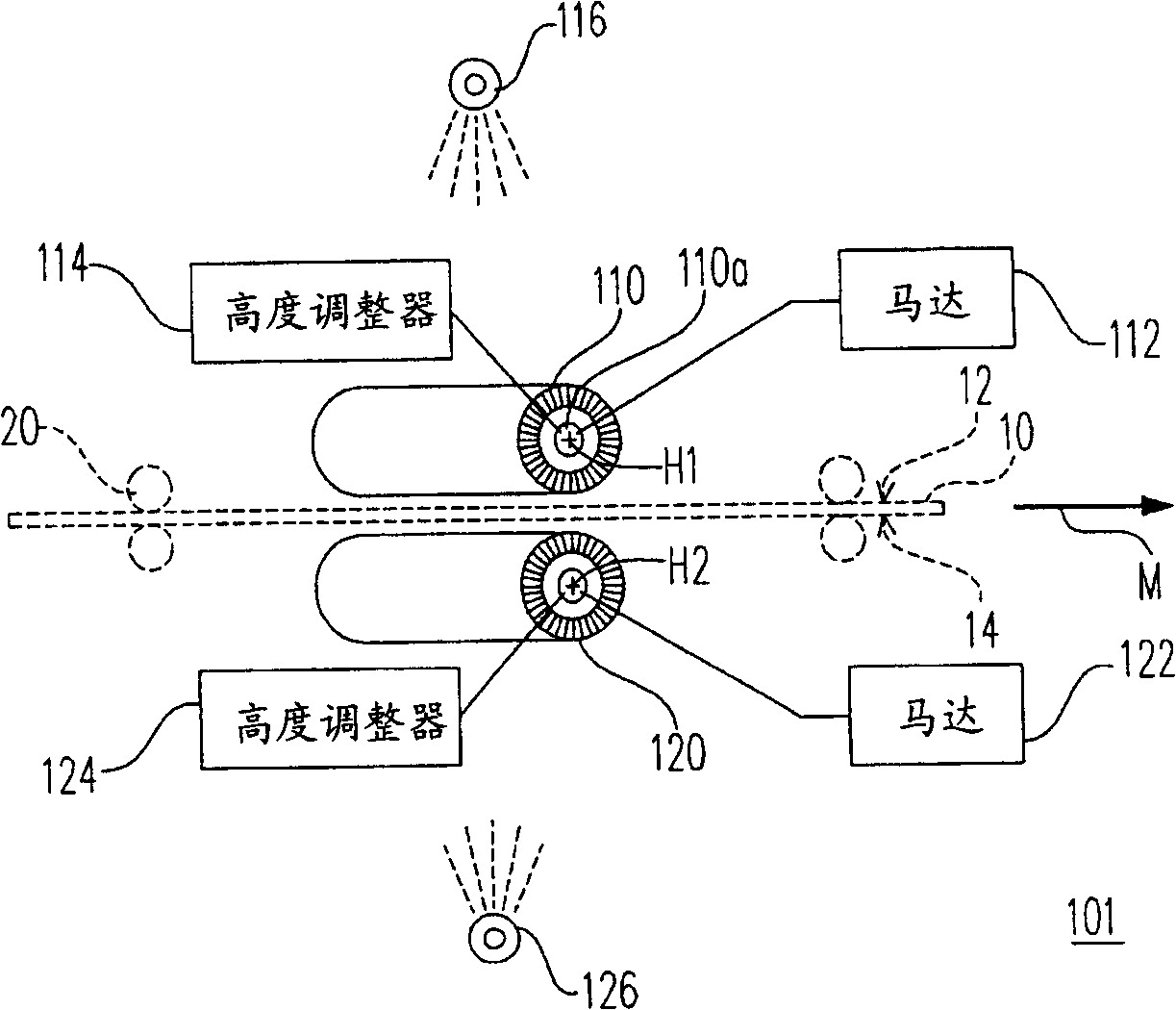

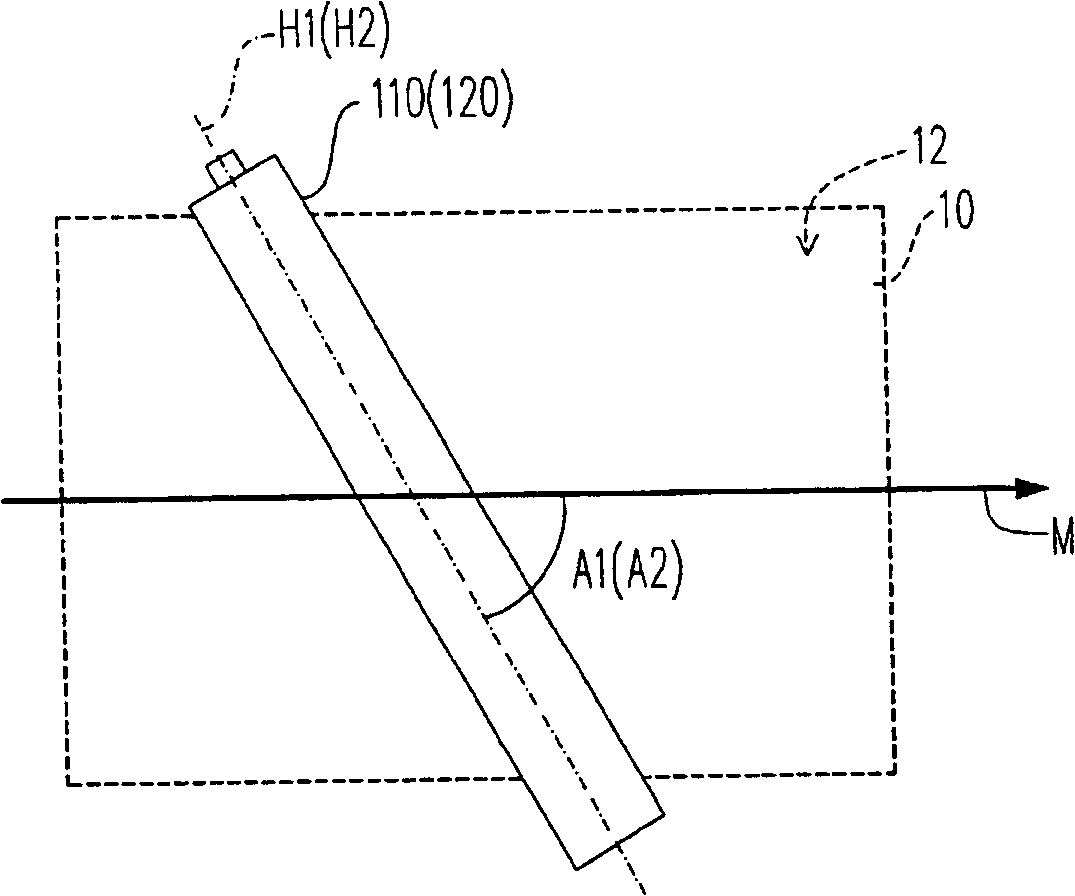

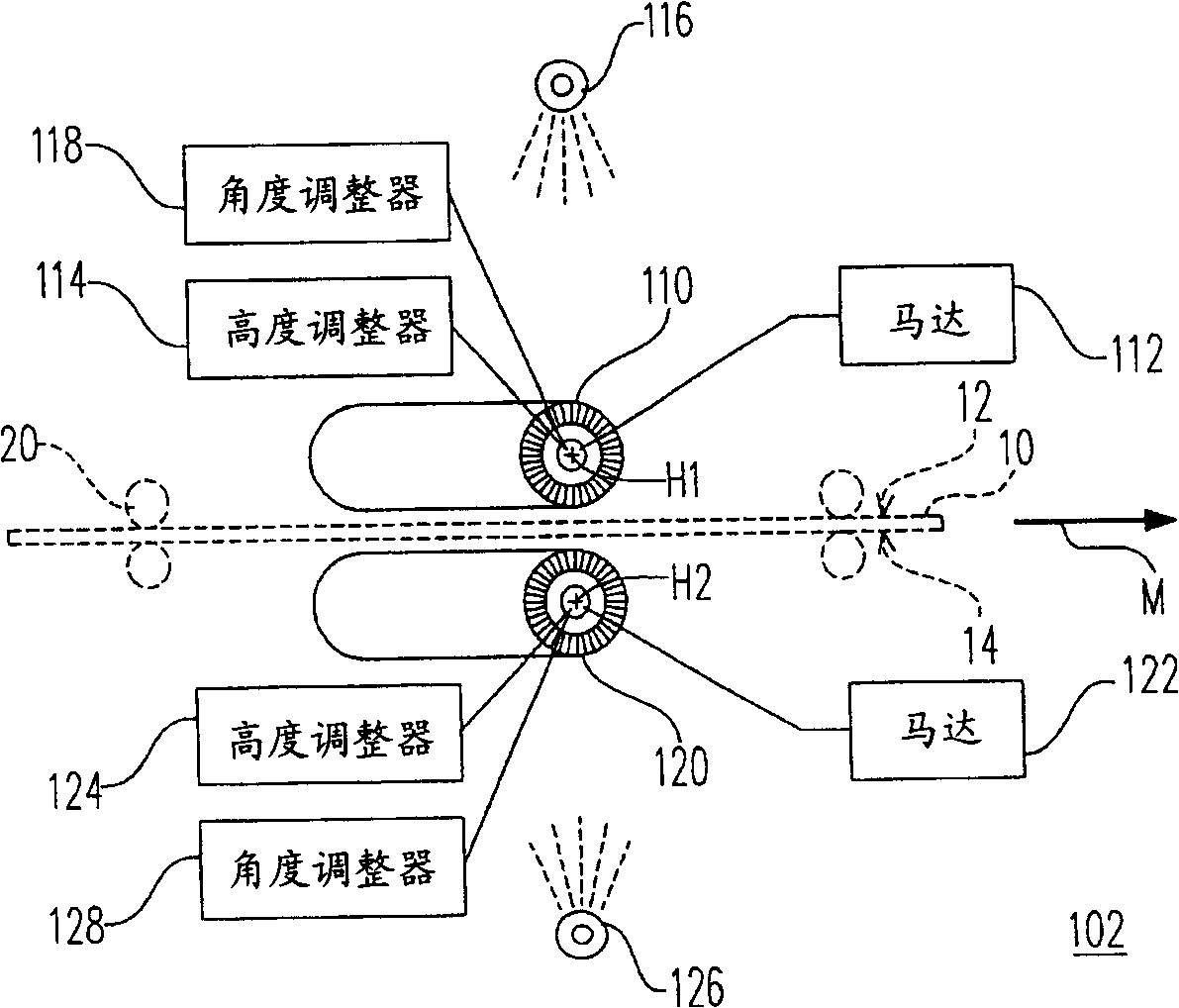

[0036] Figure 1A is a side view of a substrate cleaning apparatus according to the first embodiment of the present invention, and Figure 1B Yes Figure 1A top view of the brush wheel. Please refer to Figure 1A and Figure 1B , a substrate cleaning device 101 according to the first embodiment of the present invention is used to clean a substrate 10 moving along a moving direction M, wherein the substrate 10 can pass through a plurality of guide rollers 20 of a substrate conveying device or other The mechanism moves horizontally along the moving direction M.

[0037] In the first embodiment, the substrate cleaning apparatus 101 does not include the above-mentioned substrate conveying apparatus, but in other embodiments, the substrate cleaning apparatus 101 and the substrate conveying apparatus may also be integrated into a single device.

[0038] The substrate cleaning device 101 includes a brush wheel 110, which is pivotally disposed above the conveying path of the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com