A connection fastener for power grid line insulator and lead

A line insulation and connection fastening technology, which is applied in the installation of cables, electrical components, overhead installation, etc., can solve the problems of waste of wires, weak anti-theft, troublesome construction, etc., and achieve durable anti-theft, anti-theft, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

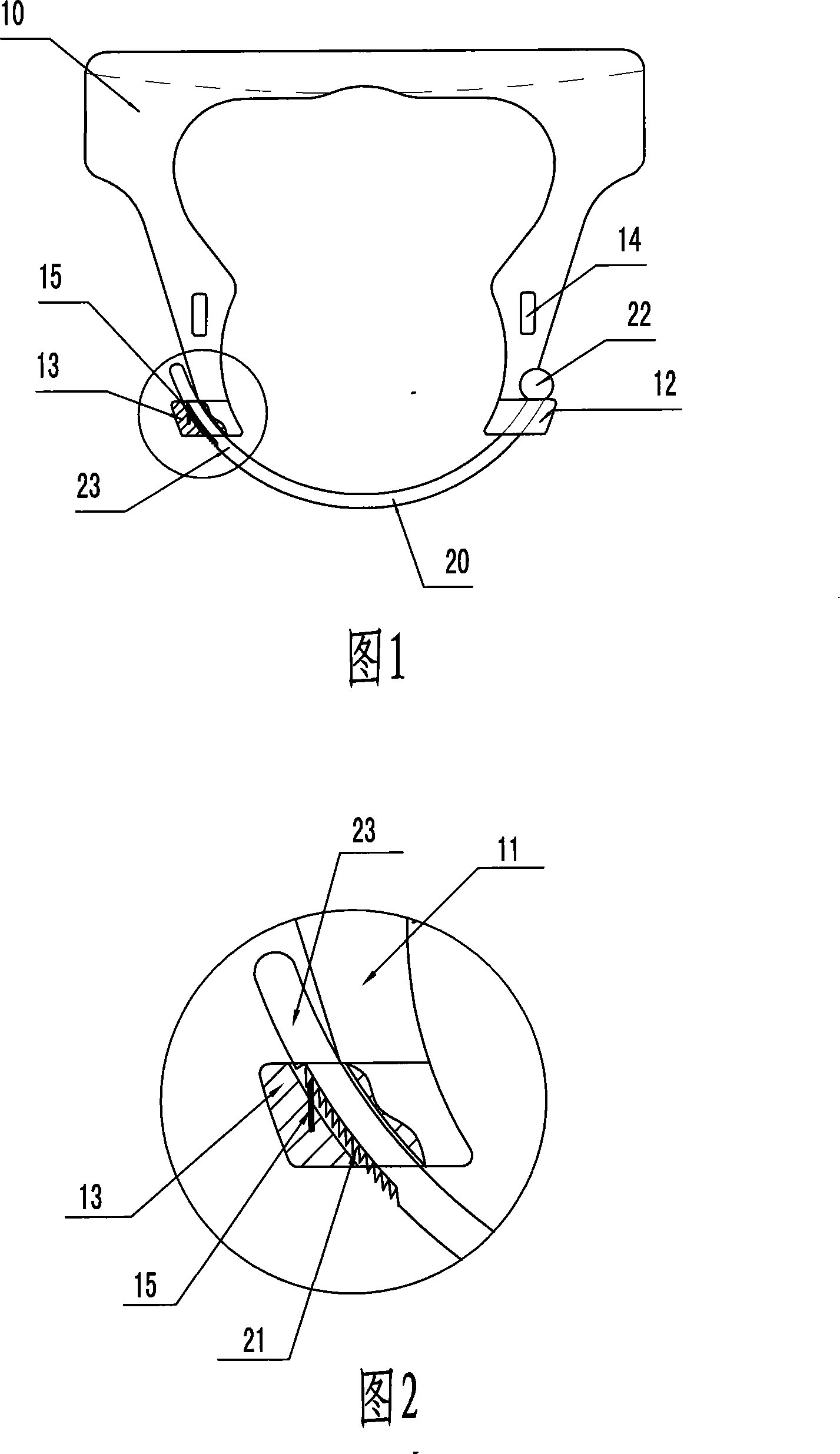

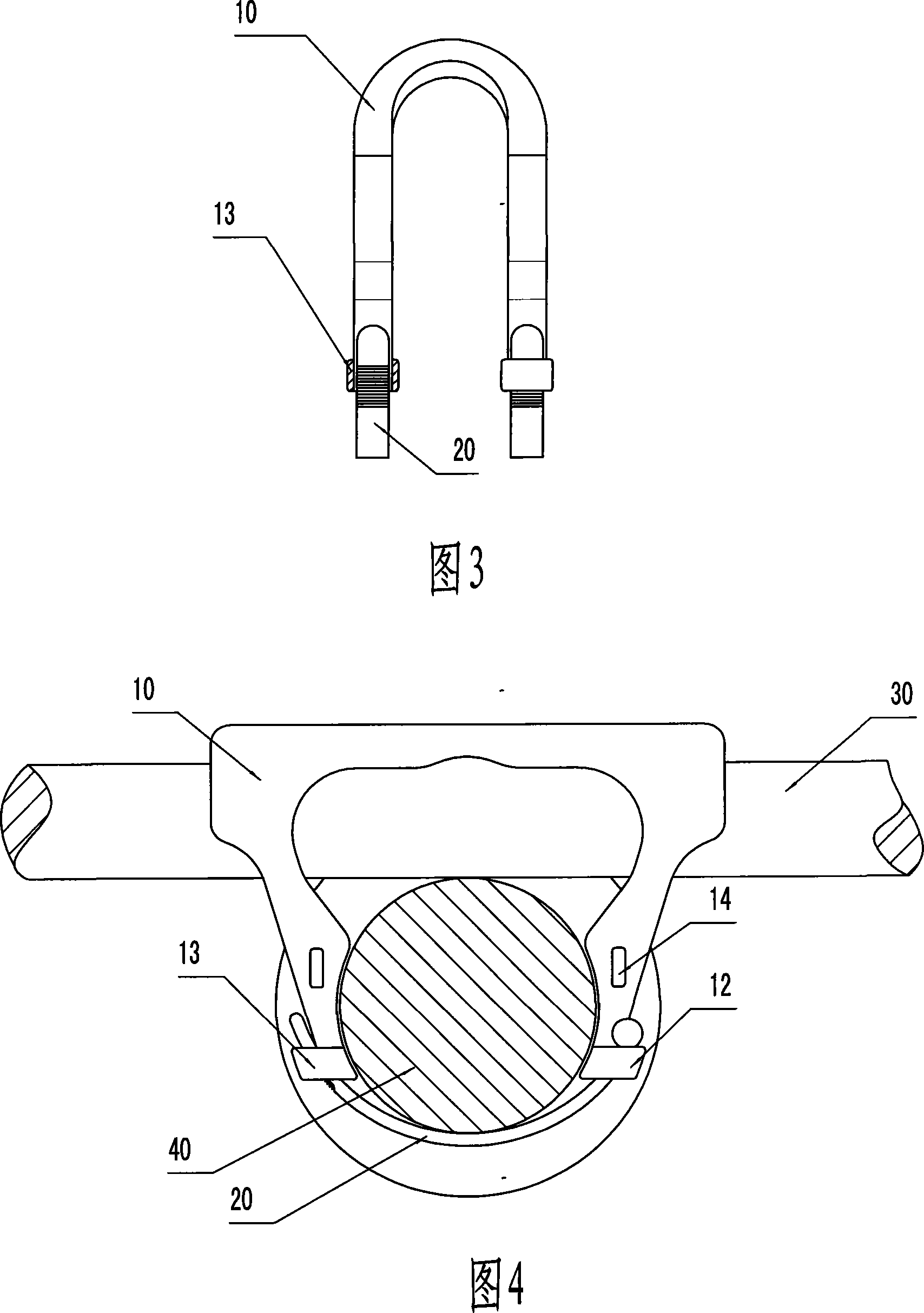

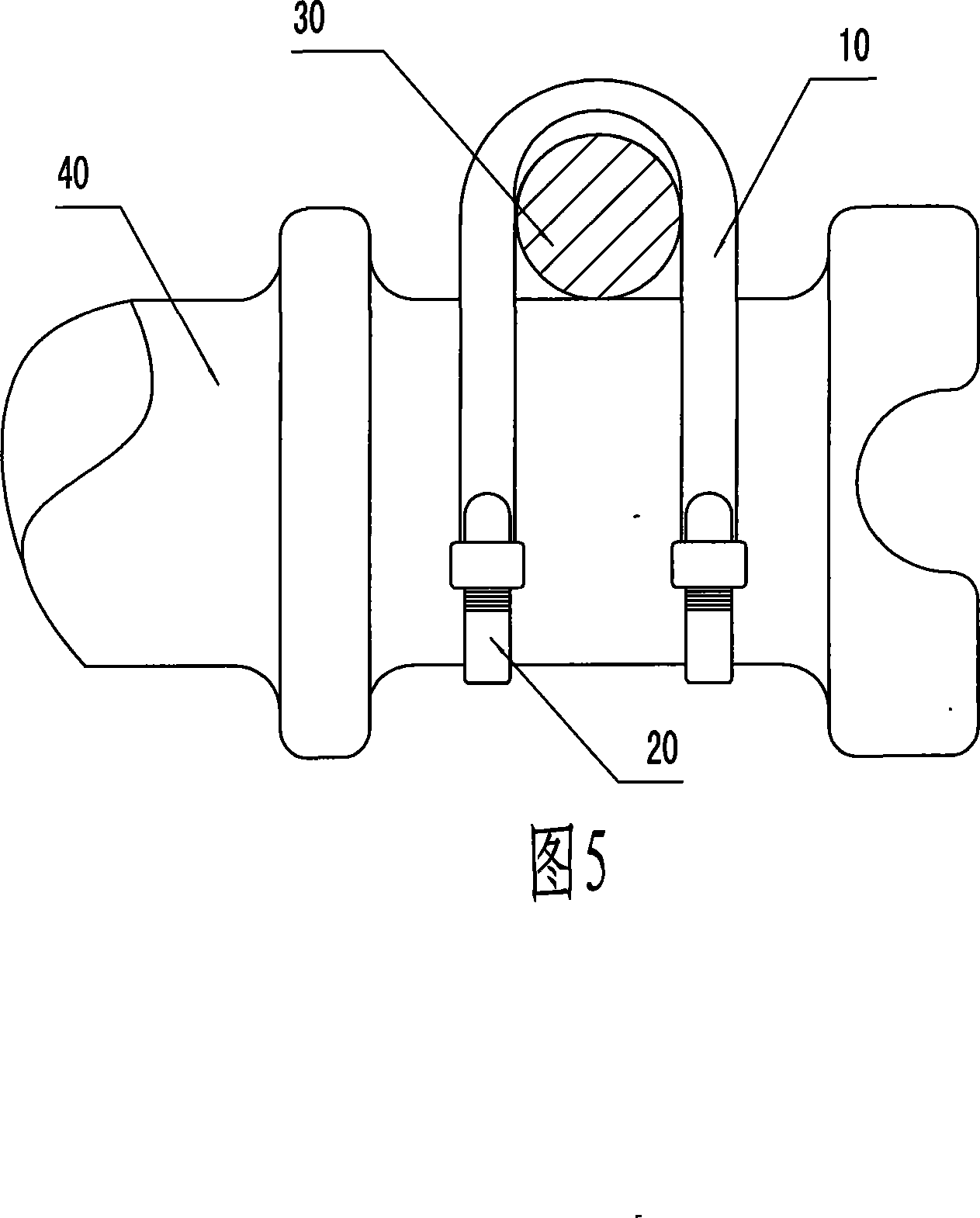

[0020] As shown in Figures 1 to 5, a fastening device for connecting power grid line insulators and wires, the connecting fastening device includes a housing 10 and a cassette 20 for connecting and fastening the housing, the housing 10 is made of high compressive strength And bendable elastic material is made, and the shape of its end face is U-shaped substantially, and wire 30 and insulator 40 are all located in housing 10, and the upper part of housing 10 has the inner circular arc that matches with the outer edge surface of wire 30 Surface wire groove, the shell 10 is placed on the wire 30 through the inner arc surface wire groove, and a hoop 11 for wrapping the insulator 40 is extended downward on the four groove sides of the two ends of the wire groove. The hoop is integrated with the edge of the slot; the hoop 11 has an inner arc surface that matches the outer edge of the insulator 40, and the hoop 11 clamps the insulator 40 through the inner arc surface, and the two hoop...

Embodiment 2

[0024] As shown in Figures 6 and 7, the difference from the first embodiment is that each hoop 11 has a through opening 14, and the openings 14 on the four hoops are symmetrically distributed, and the cable ties 50 are passed through the hoops. Symmetrically distributed openings on the hoop. This structure is suitable for the contact installation of the wire 30 and the insulator 40 in a T-shaped cross. During installation, vertically clamp the wire slot on the arc surface of the housing 10 on the wire 30, and at the same time be stuck between the wire slots of the insulator 40, and then use a cable tie 50 to pass through the four symmetrically distributed wires on the four hoops 11. A through hole 14 binds the wire 30 and the insulator 40 tightly. In order to tie tighter, also can offer more than two openings 14 on every hoop, like this as required, on the four openings of every group of symmetrical distribution, wear tie.

Embodiment 3

[0026] As shown in FIG. 8 , the housing 10 of this embodiment is made into an elbow shape, which is applicable to the bend of the wire 30 , and its installation and use methods are the same as those of the first embodiment.

[0027] In order to facilitate installation, bayonets and fastening parts can be provided at the ends of the hoops, and openings are opened in the middle of each hoop, so that the same part can be suitable for the installation needs of the above-mentioned wires and insulators in different forms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com