Automatic production technology for pu'er ripe tea

A Pu-erh ripe tea and production process technology, which is applied in the field of Pu-erh ripe tea fermentation automation production process, can solve problems such as pollution, product quality without quality traceability, quality control system and control indicators, etc., to achieve a high degree of automation and promote health Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

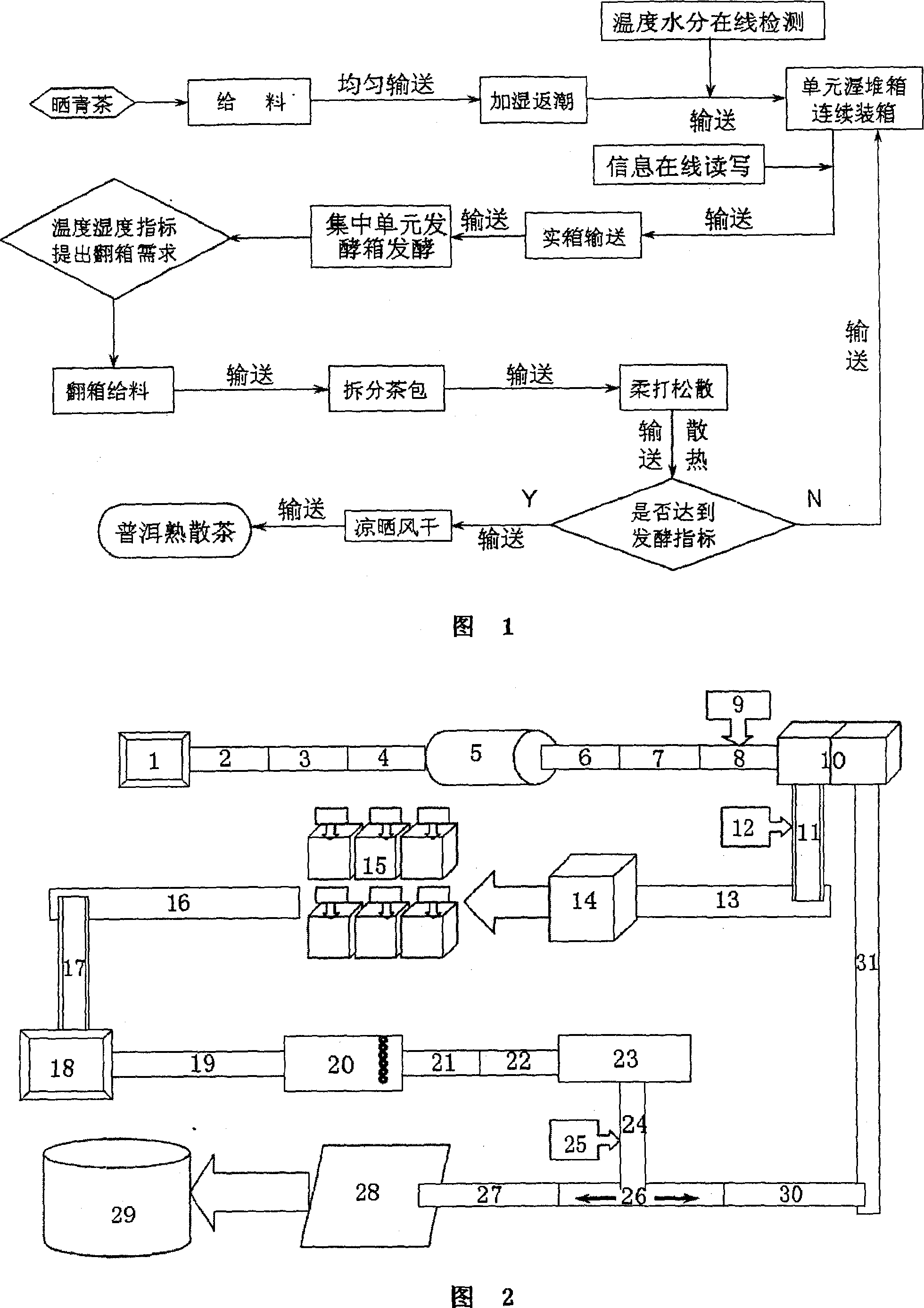

[0020] Figure 1 shows the process flow of the present invention. The automatic production process of Pu’er cooked tea of the present invention includes feeding—humidification and dampening—packing—transportation in real boxes—fermentation—extraction and turning over boxes—disassembly of tea bags—soft beating and loosening—cooling and air drying— Processes such as packaging of ripe Pu-erh tea and loose tea, especially including:

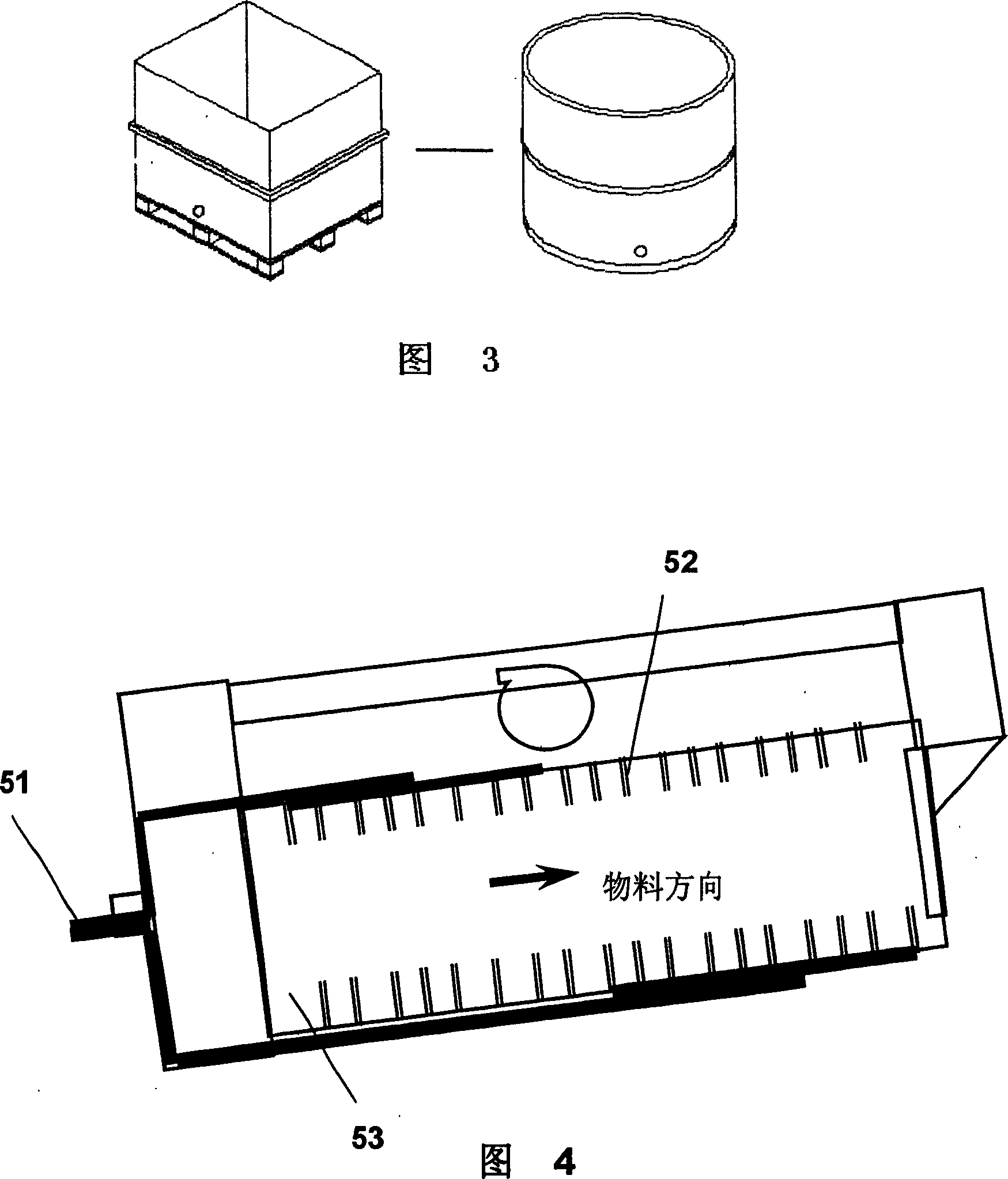

[0021] A. Boxing—feed the Pu’er tea raw material sun-dried green tea through the automatic uniform distribution boxing equipment 10, and transport the raw materials loosely and evenly into the drum-type spray humidification and moisture-resurfacing machine 5 to regulate the moisture and temperature of the stacked raw materials. The belt conveyor is sent to the unit distribution machine to automatically pack into the unit fermentation box 1026 and slightly pre-compressed;

[0022] B. Fermentation—Put the unit fermentation tanks in a ventilated and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com