Process and kit for formation of active hydrogen water, gypsum feeder for the formation, active hydrogen forming materials and process for the production of the materials

A manufacturing method and technology for active hydrogen, which are applied in the directions of inorganic active ingredients, non-living medical raw materials, and medical preparations containing active ingredients, etc., can solve the problem of wasteful consumption of metal magnesium particles, the sustainability of active hydrogen, and the difficulty of generation methods, etc. problems, to achieve the effect of high dissolved active hydrogen concentration, high sustainability, and prolonged retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

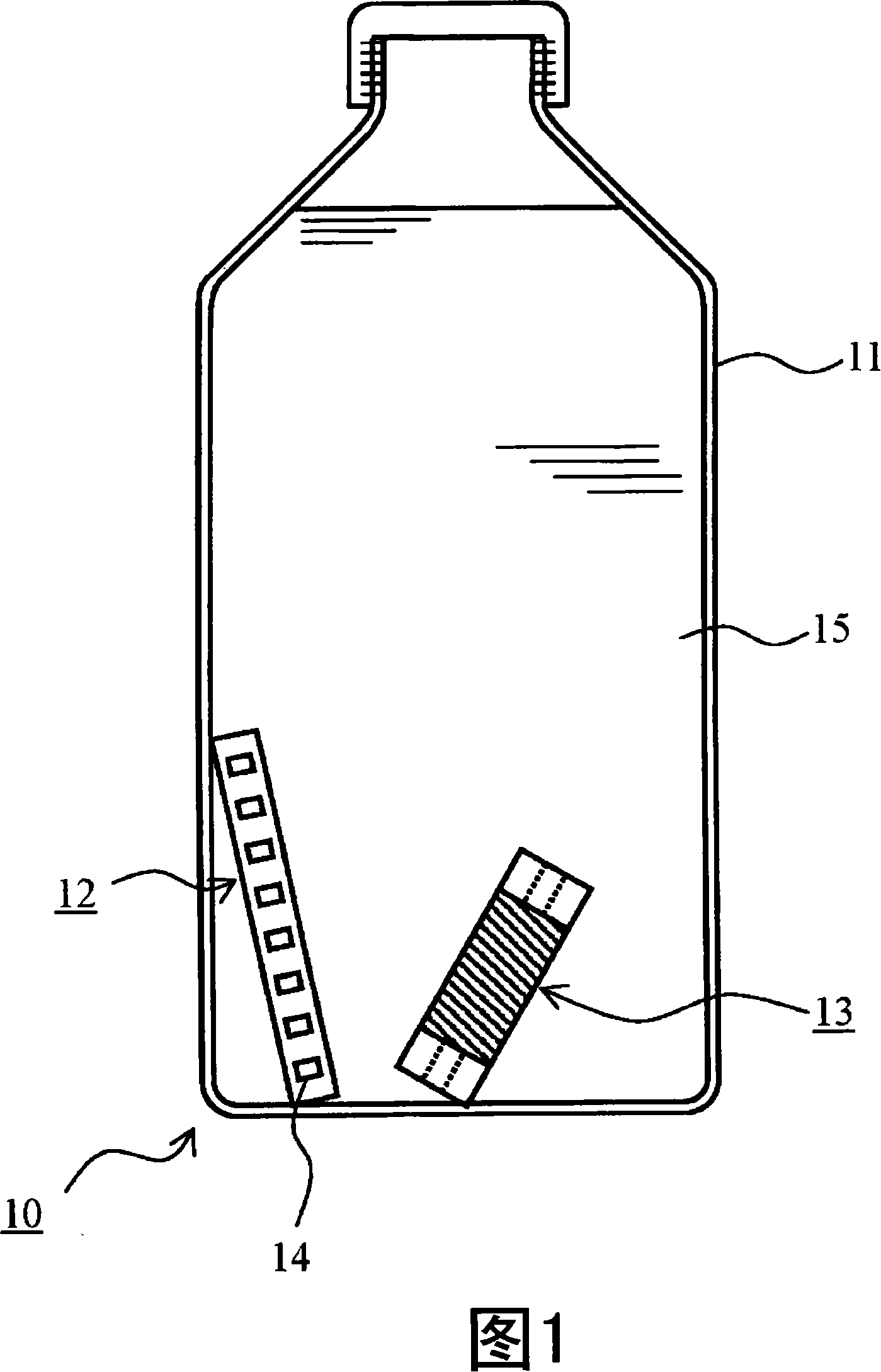

[0055] FIG. 1 is a schematic configuration diagram of an active hydrogen-dissolved water generator as an example for explaining the method for producing active hydrogen-dissolved water of the present invention.

[0056] As shown in FIG. 1 , the active hydrogen dissolved water generator 10 has, for example, a container 11 such as a PET bottle, a first box 12 filled with magnesium metal, and a second box 13 filled with gypsum. And the drinking water 15 is put in the container 11 together with the 1st case 12 and the 2nd case 13, and is stored.

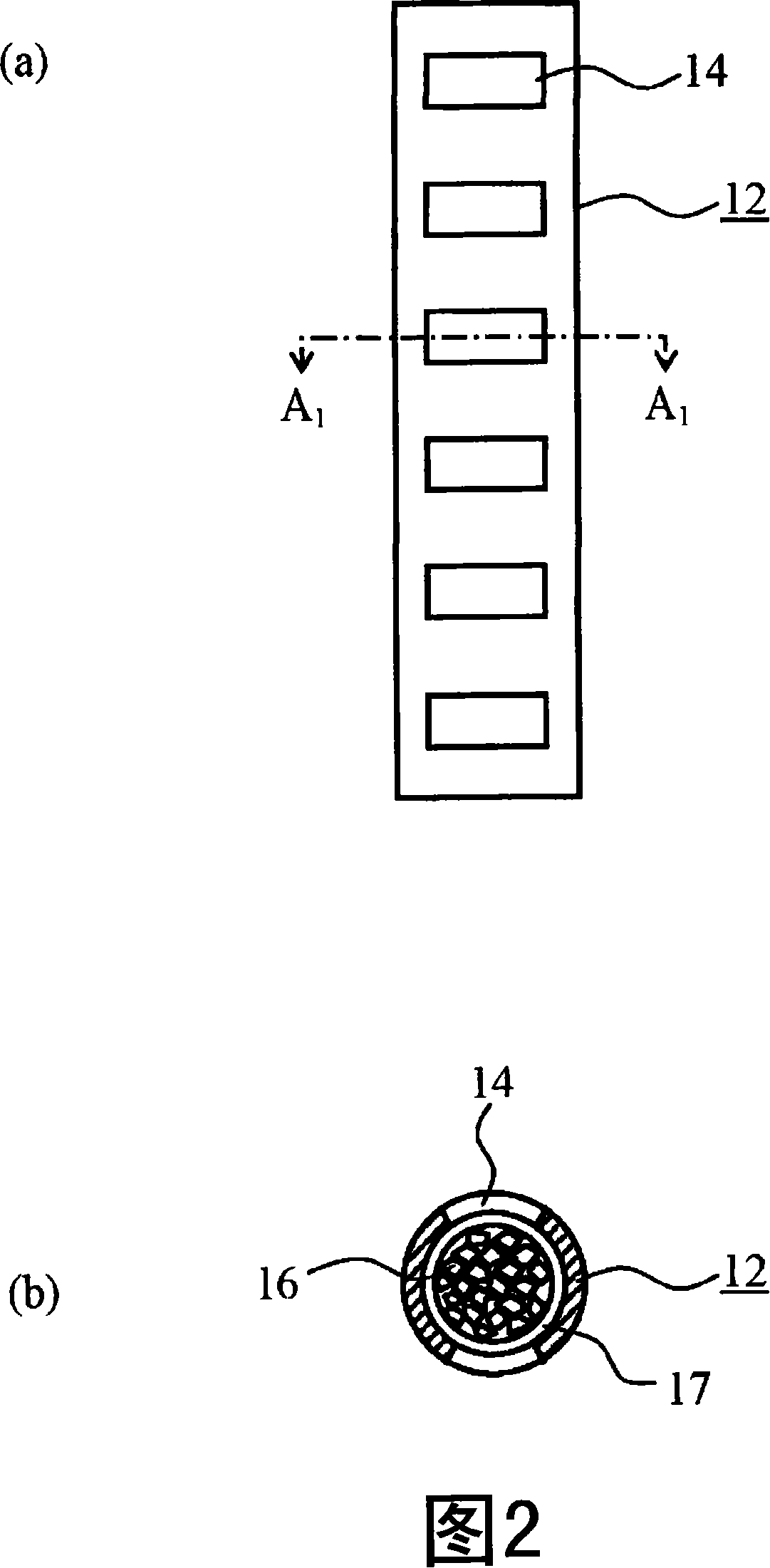

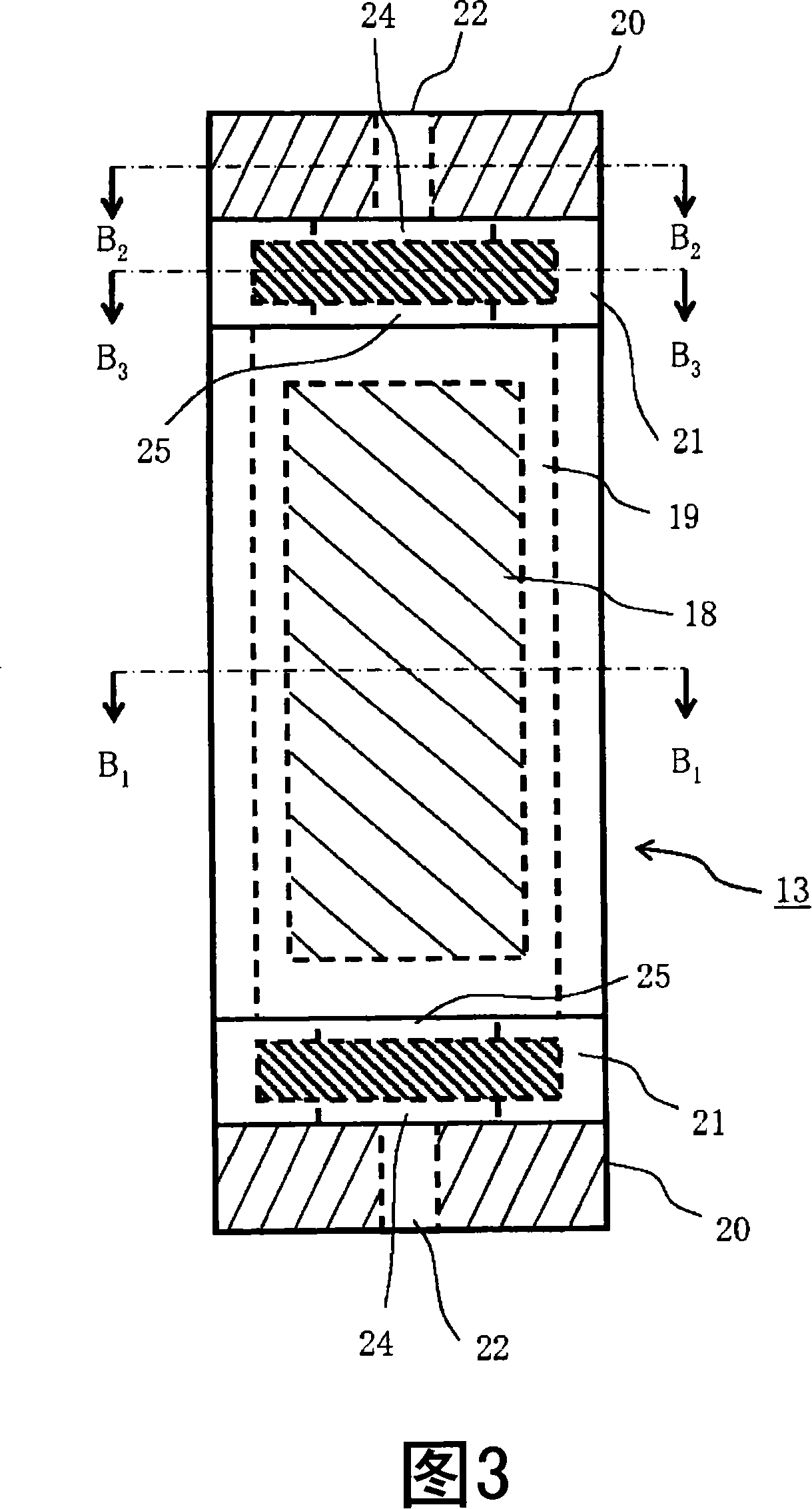

[0057] In a preferred form, the rod-shaped first cartridge 12 shown in FIG. 2( a ) and FIG. 2( b ) is used as the active hydrogen generating means. Fig. 2 (a) is the side view of the first box 12, Fig. 2 (b) is A of Fig. 2 (a) 1 -A 1 To the sectional view.

[0058] As shown in Figure 2, the first box 12 is made of elongated cylindrical plastic with a cross-sectional shape such as a circle, and a hole 14 for allowing liquid to go in an...

Embodiment approach 2

[0101] FIG. 9 is a schematic configuration diagram of another active hydrogen-dissolved water generator as an example of the method for producing active hydrogen-dissolved water according to the present invention. Embodiment 2 is characterized in that a solid mixture of gypsum and metallic magnesium particles is used.

[0102] As shown in FIG. 9 , the active hydrogen dissolved water generator 10 a has, for example, a container 11 such as a PET bottle, and a common box 31 filled with a hydrogen generating solid made of a mixture of gypsum and magnesium particles described later. And the drinking water 15 is put into and stored in the container 11 together with the said common box 31. As shown in FIG.

[0103] In the generator 10a having the above configuration, the method and mechanism of generating the active hydrogen-dissolved water are basically the same as those described in the first embodiment. That is, as shown in FIG. 9, if normal temperature or cooled drinking water 1...

Embodiment approach 3

[0126] Next, Embodiment 3 will be described with reference to FIG. 15 . This embodiment is a case where the magnesium metal generated by the above-mentioned active hydrogen is not mixed with gypsum, but is separately enclosed in the common box 51 .

[0127] The common box 51 is made of elongated cylindrical plastic, for example, and has a structure in which magnesium metal 47 and plaster 33 are alternately arranged as shown in FIG. 15 .

[0128] In Embodiment 3, in generating the active hydrogen dissolved water, the common box 51 is accommodated in the container 11 containing the drinking water 15 in FIG. 9 . And, the drinking water 15 entering through the hole 41 reacts with the magnesium metal 47 in the sealing chamber 35 according to Chemical Formula 1 to generate active hydrogen. In addition, the drinking water 15 entering through the hole 41 dissolves the dihydrate gypsum 33 enclosed in the chamber 35 to generate dissociated calcium hydrate ions. And, this calcium hydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com